Maintenance

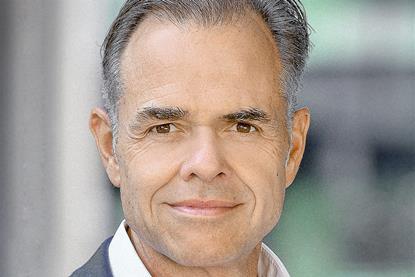

Video: Arno Güllering on transforming Dräxlmaier’s global production

Dräxlmaier COO Arno Güllering shares how the company is advancing smart factory strategies through cloud systems, AI-powered maintenance, and mindset shifts across its global operations.

Tunç Kip: Human-Machine Interfaces the key to optimised production

Human-Machine Interfaces are key to enhances productivity across auto plants from Munich to Michigan and beyond.

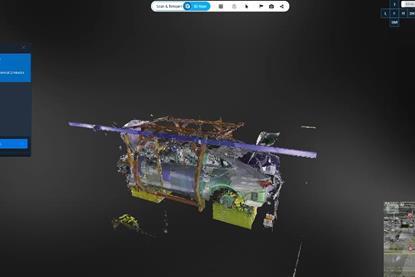

Register now: Scan-First Digital Twins: A reality capture roadmap for agile, ROI-focused brownfield transformation

Discover how a leading US-based OEM is using Cintoo’s scan-first digital twins to streamline factory upgrades, reduce risk, and drive ROI. Learn how Cintoo’s reality capture platform enables faster decision-making, remote collaboration, and agile responses to supply chain disruptions. Perfect for OEMs, EV manufacturers, and suppliers navigating today’s volatile automotive landscape.

Arno Guellering on harnessing shopfloor visualisation and genAI in Draexlmaier production

COO Arno Güllering wants to build on the tier-1 supplier’s highly connected production to ensure both plants and HQ have a mindset ready to embrace change.

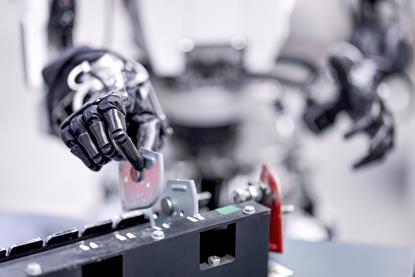

Humans and machines converge for Mercedes-Benz’ vehicle production

Mercedes-Benz is merging human expertise with AI and robotics to redefine how vehicles are built, from chatbots to humanoids and shopfloor analytics.

Cybersecurity: Building defence-in-depth into smart factories

Smart factories are vulnerable to growing cyber threats as IT and OT systems converge. Siemens outlines a holistic cybersecurity approach rooted in IEC 62443, Zero Trust, and defence-in-depth principles to protect digital enterprises and ensure resilient, sustainable industrial operations.

A conversation with JLR’s Tomasz Jozwiak: end-to-end asset reuse for EVs

JLR is redeploying surplus robots, pumps and tooling from Castle Bromwich to EV sites worldwide, cutting costs, CO₂ and boosting resilience through circularity.

Human-Machine Interfaces at Mercedes, Volvo, Ford, and GM

AR, AI vision, cobots and digital twins are redefining how carmakers train staff, plan lines and inspect quality through smarter human-machine collaboration.

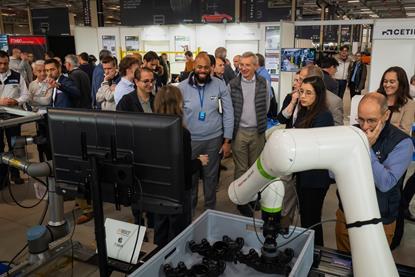

When machines talk back: How HMIs are rewiring the factory floor

Discover how next-gen HMIs are reshaping automotive manufacturing - from predictive AI dashboards and cobot coordination to ergonomic innovation and immersive digital training platforms.

Mercedes-Benz, BMW & Dräxlmaier embrace agile, digital ecosystems

Mercedes, BMW and Dräxlmaier turn to AI, robots and digital tools to boost efficiency, sustainability and flexibility in production and supply chain

GAME Theory: Is Tesla’s “Unboxed” process a new production paradigm?

Tesla’s “Unboxed” manufacturing process promises to halve production costs and redefine car assembly. Is it the game-changer the industry needs?

5G networking: How JLR is building smarter factories

Steve Mason, JLR’s Advanced Digital Technologies Manager for Global Industrial Operations speaks to AMS about the integration of 5G networks into factory environments.

Smart factories reshape automotive job roles

Digital change in automotive plants is fuelling demand for AI, data and IIoT roles, while reshaping traditional job profiles on the factory floor.

Digital twins: Boosting productivity in automotive manufacturing

Digital twins are becoming invaluable to manufacturing operations but there is more potential yet to be realised.

Edge computing and AI: Transforming manufacturing at the source

In modern manufacturing, edge computing is becoming a game changer, enabling faster, more secure, and more efficient operations.

Building better digital twins: Optimising visibility across production operations

Learn how Cintoo’s digital twin platform is helping BMW, HORSE, and others modernise brownfield plants and improve automotive manufacturing operations.

These are the strategies for the Software-defined Vehicle (SDV)

SDVs are shifting value creation in the auto industry, with OEMs racing to develop software, form tech alliances, and launch new digital revenue streams

Siemens’ OT networking blueprint: Transforming automotive manufacturing with digitalisation

How a future-ready OT network can drive efficiency, security, and flexibility in smart factories.

Audi leads with virtual controllers in vehicle bodyshop automation

Audi and Siemens debut virtual controllers in Böllinger Höfe, marking a milestone in digital factory automation and sustainable production

Digital twins are catalysts for automotive production strategies

This is how Automakers are leveraging digital twins to optimise production, cut costs and adapt to electrification, making factories more agile and efficient. Stellantis, Webasto, and Cintoo disclose…

Mercedes-Benz excels in connected manufacturing at Berlin-Marienfelde

Mercedes-Benz is reshaping production with AI, cloud platforms and smart tools at its Berlin campus, setting a digital benchmark for global automotive plants

Digital twin technology: Bridging the physical and digital worlds

As the automotive industry shifts towards electric and autonomous vehicles, digital twins are becoming essential in optimising design, engineering and production.

JLR creates 150 EV manufacturing roles in the UK

JLR is recruiting 150 EV technicians in the UK to support the production of Range Rover Electric and next-generation battery and drive unit manufacturing.

Mercedes-Benz advances AI and robotics in production

Mercedes-Benz is redefining production at Berlin-Marienfelde with AI and humanoid robots, pioneering digital manufacturing methods for a more intelligent future.

European automotive production in dire need of efficiency gains

A McKinsey report warns that Europe’s automotive sector is losing ground in global markets. Without decisive action, its competitive edge may erode even further.

Henkel’s advanced thermal management for ADAS reliability

ADAS domain controllers generate extreme heat, threatening performance and longevity. Henkel’s latest thermal interface material ensures efficiency and reliability.

Revolutionising Automotive Manufacturing: Flexibility, Efficiency, and Sustainability with Siemens

Discover how Siemens’ innovative solutions empower automakers to meet the challenges of EVs, sustainability, and smart manufacturing. Download the whitepaper to explore actionable insights.

Renault boosts sustainability with Poland’s new ‘Renew Factory’

Renault launches a sustainable repair facility in Poland, targeting the booming used car market while cutting costs and carbon emissions for refurbished vehicles.

Verne begins constructing Croatia’s first autonomous EV plant

Verne has begun construction on Croatia’s first autonomous EV plant at VGP Park Zagreb, a project set to boost the region’s role in future mobility and green tech.

Revolutionising Automotive Manufacturing: Flexibility, Efficiency, and Sustainability with Siemens

Discover how Siemens’ innovative solutions empower automakers to meet the challenges of EVs, sustainability, and smart manufacturing. Download the whitepaper to explore actionable insights.

TCS’ Anupam Singhal on offsetting EV cost and sustainability doubts

A recent Tata Consultancy Services (TCS) study found 64% of consumers are open to EVs, yet cost and sustainability concerns remain. AMS interviews Anupam Singhal, TCS’ president of manufacturing to find out how manufacturers and policymakers can now shape the transition to electrification

Europe’s $208.4bn AI investment to catapult automotive production

The EU’s InvestAI fund will drive AI adoption in automotive, supercharging manufacturing with smart factories, enhanced automation, next-gen production technologies.

VW adopts Dassault’s AI-driven cloud platform for vehicle development

Volkswagen will implement Dassault Systèmes’ AI-driven 3DEXPERIENCE cloud platform to accelerate software-defined vehicle development and streamline processes.

What does China’s Deepseek AI mean for the automotive industry?

DeepSeek’s AI claims to train models with minimal Nvidia chips, shaking Wall Street and raising questions about computing power in automotive AI.

Rockwell expands with Clearpath Robotics acquisition

Rockwell Automation completes its acquisition of Clearpath Robotics and OTTO Motors, expanding its autonomous material handling capabilities in smart factories.

Audi wants to define new standards for AI image processing

Audi is driving AI innovation in vehicle production with advanced image processing, eliminating errors and setting new quality benchmarks for the smart factory era.

AI: Enhancing predictive maintenance in production lines

For predictive maintenance strategies AI now offers a significant step forward in real-time monitoring and data gathering and analysis.

Data-driven decision-making for sustainable automotive production

Data-driven decision-making is revolutionising automotive manufacturing. By leveraging AI and big data analytics, OEMs and suppliers are optimising operations, minimising waste, and achieving ambitious sustainability goals.

How BMW’s San Luis Potosí leads in sustainable production

BMW’s San Luis Potosí plant sets benchmarks in solar power, water recycling, and AI-led sustainability, making it a global leader in green automotive manufacturing.

How AI is shaping the future of automotive manufacturing

Explore how AI is transforming automotive manufacturing with advanced technologies like predictive maintenance, deep learning, and generative design.

Subscriptions terms and conditions

1) User Acceptance of Terms of Service

2024 to 2025, the trends and predictions in automotive production

Explore 2024’s top advancements in auto manufacturing, from EV battery innovations to sustainable production strategies, and discover what’s shaping the future, and predicitons for 2025

Skoda: “We need clarity in production about where the path leads”

Andreas Dick shares Skoda’s vision for digitisation and flexibility, tackling the challenges of electromobility, AI, and sustainable production.

Smart Factory: BMW’s digital production at San Luis Potosi, Mexico

BMW’s San Luis Potosi plant sets standards in automotive production with AI, digital twins, and sustainable innovation, leading the charge toward electrification.

Blueprint for building the smart factory of the future

The concept of the smart factory offers highly efficient, optimised production operations. Ford, ZF and PPG reveal how they are working to realise this potential.

Hyundai Kia’s ‘Wearable Robot’ with vehicle production applications

Hyundai and Kia’s X-ble Shoulder robot promises a revolution in worker safety, reducing injuries and enhancing efficiency across industries.

Smart manufacturing: Data, AI, and digital transformation

Manufacturing operations are working with new software and hardware developments, and artificial intelligence, but challenges remain in optimising these opportunities.

AMS Evolution 2024: Recap blog

Get insights on technologies like AI, robotics, and sustainable production systems driving flexibility and zero waste in factories at the second AMS Evolution North America Conference 2024

This is how efficiently the VW plant in Portugal works

VW’s Palmela plant keeps running efficiently with lean principles, 90% automation, and innovative 3d printing, ensuring the success of the t-roc and its successor. This is how…

VW's Thomas Hegel Gunther: “We cannot afford to make any mistakes”

The Volkswagen Autoeuropa plant in Portugal is a testament to the power of continuous improvement and efficient production and logistics. Despite being over three decades old, the factory has consistently achieved high levels of productivity and received recognition for its lean practices.

Stellantis turns to AI tools and fast deployment to cut production costs and launch times

Stellantis manufacturing boss Arnaud Deboeuf reveals technologies in automation, factory planning and lineside logistics that reduce transition costs and time to market.

Volvo’s 100% EV strategy shift: facing the unavoidable truth

Lower-than-expected EV sales continues to have repercussions for production plans, with Volvo the latest vehicle maker to delay 100% EV target.

Rockwell Automation appoints sustainability leader

Industry-leading automation company bolsters commitment to environmental and social responsibility with new VP of Sustainability.

Antolin, Gestamp and Fersa using AI to improve production operations

Spanish parts makers are pushing process improvements across their businesses using the latest digital technology

Top 5 EV battery chemistries and formats across the world

Battery technology is paramount to the electrification drive from cell chemistries such as Lithium Iron Phosphate (LFP) and Lithium Nickel Manganese Cobalt Oxide (NMC) to architectures like prismatic or cylindrical cells. We look at cost, performance and more.

Tesla’s EV battery production and global gigafactory network

Tesla’s growing network of gigafactories, including new sites in Berlin, Texas, and Shanghai, demonstrates its commitment to leading global electrification.

Virtual production networks are able to solve diverse complexities

This is how digital twins are reshaping automotive manufacturing from enhanced simulations to greater flexibility and global collaboration.

Exclusive: BMW Group improves efficiency with additive manufacturing gripper

AMS visited BMW Group’s Additive Manufacturing Campus and plant in Munich to see it 3D-printed bionic robot grippers, which are saving costs and emissions and improving efficiency across its plants.

How Mercedes-Benz and Seat are transforming their plants

Both Mercedes-Benz and Seat are transforming their plants to increase sustainability and digitalisation, but it hasn’t all been smooth sailing.

Ford Otosan and how automation is driving production of the Transit

Ford Otosan’s Kocalei site is one of the most advanced production facilities in the world, producing the highest number of derivatives with the widest range of powertrains. Complexity

Ford Otosan manufacturing for an economy in transition

Ford Otosan has upgraded its manufacturing facilities in Turkey to ensure the Transit is ready for an electrified future

Audi: “We have a clear strategy towards electromobility”

Gerd Walker illuminates Audi’s innovative strategies for sustainable, flexible production and the transition to electric vehicles

GM and Honda JV ‘FCSM’ begins producing hydrogen battery fuel cells

GM-Honda collaboration FCSM kicks off hydrogen fuel cell production at its Michigan plant, setting a new standard in sustainable battery technology

ACC raises €4.4 billion for three gigafactories in Europe

Europe is becoming an increasingly popular region for battery manufacturing, with ACC, CATL, Northvolt and Farasis setting up production facilities across the continent.

Powertrain – Reducing waste in machining fluids

JLR offers a very interesting sustainability case study on powertrain production processes at its Electric Propulsion Manufacturing Centre.

JLR – Putting sustainability at the centre of its strategy

JLR’s manufacturing sustainability transformation lead, Garrett Bell, shares some insights in how the business is reducing its carbon footprint across its operations

How Farasis will bridge the battery gap in Europe

Farasis has appointed Marcel Brömlage to lead its European division and support the growth of its Siro joint venture gigafactory in Turkey, where it expects to produce battery cells by 2026.

Design and manufacturing integration, digitalisation key to cost and sustainability gains for BMW’s Neue Klasse

To realise large cost and emission savings on its EV architecture, BMW is redesigning vehicles and manufacturing in parallel, and rolling out rapid digital solutions.

The state and stipulation of automotive production: Retrospect 2023 to prospect 2024

In 2023, the automotive industry underwent a transformative journey, adapting to trends such as sustainable materials, electric vehicle dominance and digitalisation. But what clues does 2023 provide about the vehicle manufacturing landscape in 2024?

Simultaneous engineering – accelerating production line design, development and commissioning

The transition to electric vehicles has increased pressure on speeding product development and starting production operations

Renault announces Re-Industry roadmap to transform production base

Renault Group’s Re-Industry initiative aims to transform its manufacturing base for cost efficiency and sustainability by leveraging the Industrial Metaverse, AI applications, and agile practices.

UK Government injects £2bn into automotive industry to drive sustainable growth: Nissan leads

The UK government’s £4.5bn initiative prioritises the automotive sector with over £2bn, signaling a green push. Nissan swiftly invests £2bn in three EV models.

Henkel powers EV evolution with cutting-edge battery sealing technology

Innovative solutions from Henkel ensure safety, reliability, and durability for EV battery manufacturers worldwide, setting new standards in performance.

BMW: ‘Flexibility is in our genes’

BMW, Mini and Rolls Royce are driving a tight electrification course. Nevertheless, the group remains open to drive diversity. In an interview, production director Milan Nedeljković talks about flexibility and the concept of the iFactory.

Fanuc and Volvo Cars sign deal to transform automotive manufacturing with sustainable robotics

In a landmark collaboration, Fanuc, the global leader in industrial robotics, and Volvo Cars are to reshape auto manufacturing with sustainability at the forefront

The future of Ford in a flash of lightning

The Ford Dearborn Truck Plant is a benchmark for managing complexity, quality and software. Plant manager Corey Williams shares learnings and lean principles across ICE and fast-growing EV output.

Toyota addresses production system malfunction that put the breaks on Japanese production

The OEM finally releases statement regarding the nationwide disruption; identifying “insufficient disk space.”

Rising EV production boosts demand for more advanced automation

Advanced automation could be the key to challenges in battery production, according to ABB.

Qualcomm’s collaborations with leading automakers to reshape automotive manufacturing

Partnerships with BMW, Mercedes, JLR and Mahindra revolve around automotive digital advancements and driving industry transformation.

Continental digitises European automotive manufacturing plant with a private 5G Network

The private 5G network is powered by T-Mobile in Czechia. With plans to integrate over 1,000 devices and sensors within the plant’s expansive 5,000 square metres, the company’s smart network promises to create an interconnected ecosystem that enables seamless communication between employees, machinery and devices such as sensors, production robots and autonomous transport vehicles.

JLR to boost West Midlands workforce for new body shop and EVs

JLR will recruit 300 technicians and engineers for body shop production, testing and development, highlighting its commitment to West Midlands manufacturing and electric vehicle innovation.

BMW Batteries blossoming in South Carolina

BMW’s battery assembly plant will use advanced automation and set global standards, whilst supporting a local-for-local production strategy, says Rich Everly.

Audi’s ‘Edge Cloud 4 Production’ ecosystem launches into serial production

EC4P is an IT-based production system that leverages Edge and Cloud technology to digitise the automotive production landscape and is the first of its kind to go into serial production.

Audi uses AI for quality control of spot welds

The carmaker is officially using the technology after successful trials.

Case Study: Daimler Relies Upon HiveMQ During Automotive Manufacturing

Learn how and why Daimler uses HiveMQ to manage information flow between vehicle diagnostics system test devices on the factory floor and server-side enterprise IT systems

Seat: Digital tools, shopfloor innovations and multi-brand manufacturing

Markus Haupt has returned to his professional roots in Barcelona. As the board member in charge of production and logistics, he now has the fortunes of Seat’s manufacturing operations in his hands

Smart Factory Special Edition - Automobil Produktion

Read about the latest developments in Industry 4.0 featuring SEAT, Audi and more from AMS sister publication Automobil Produktion in this special edition for the Hannover Messe

Solving electric vehicle production challenges with smart manufacturing and logistics

Siemens discusses how the latest digital tools are enabling the transition to e-mobility and explains why these are now essential to OEMs and tier suppliers if they are to create transparent, sustainable supply chains

Tools for progress: real-time tracking and monitoring in Audi’s toolmaking

The carmaker’s Toolmaking 4.0 system is bringing greater visibility of suppliers and potential disruption of machines and operations at tool shops, with high productivity gains.

Building on the edge of the virtual and physical worlds

As Audi aims to bring its local production cloud to plants, Jörg Spindler sees opportunities in digital control systems, digital twins and virtual reality.

Special series: Digitalising manufacturing engineering at Audi

Jörg Spindler is leading Audi’s push to virtualise production planning, ramp up battery production and use data to reduce emissions and improve productivity in areas like toolmaking and body shop

AMS Automotive Evolution Europe – a review from Munich 2022

The first AMS Evolution Europe Summit saw experts from BMW, Audi, ZF CATL and more discussing speeding time to market, greater agility in production, factory conversion and boosting battery cell manufacturing in the region.

Digitalisation: Solving EV production challenges with smart manufacturing

Autonomous vehicles, electrification, and shared mobility are the key trends influencing the strategy and investments for most automotive manufacturers and suppliers today. These are causing automakers to rethink their business models and prepare themselves for fundamental changes in their design, manufacturing, and aftermarket processes. Siemens looks at how digitalisation can ...

After baptism of fire, BMW plant has room to grow in Mexico

Under Mexico plant director Harald Gottsche, BMW has launched new models during the pandemic, navigated supply disruptions, integrated new technology and maintained staff levels – and it’s ready to expand.

Škoda sets sights on 70% EV mix by 2030, more climate-neutral plants in Czech Republic

Skoda production chief and VW Group veteran Michael Oeljeklaus sets out the Czech brand’s route map to more EVs and more efficiency in this exclusive interview.