Simultaneous engineering – accelerating production line design, development and commissioning

The transition to electric vehicles has increased pressure on speeding product development and starting production operations. AMS spoke with experts at NIO and Comau on how they had successfully accelerated the commissioning of new e-motor lines

Competition is fierce as OEMs race to establish a foothold in the growing global electric vehicle (EV) markets. This has placed increased pressure on developing new products and starting volume production, with timescales being slashed. So, how is this being achieved without compromising line efficiency and product quality? A very interesting case study comes from a collaboration between NIO and Comau.

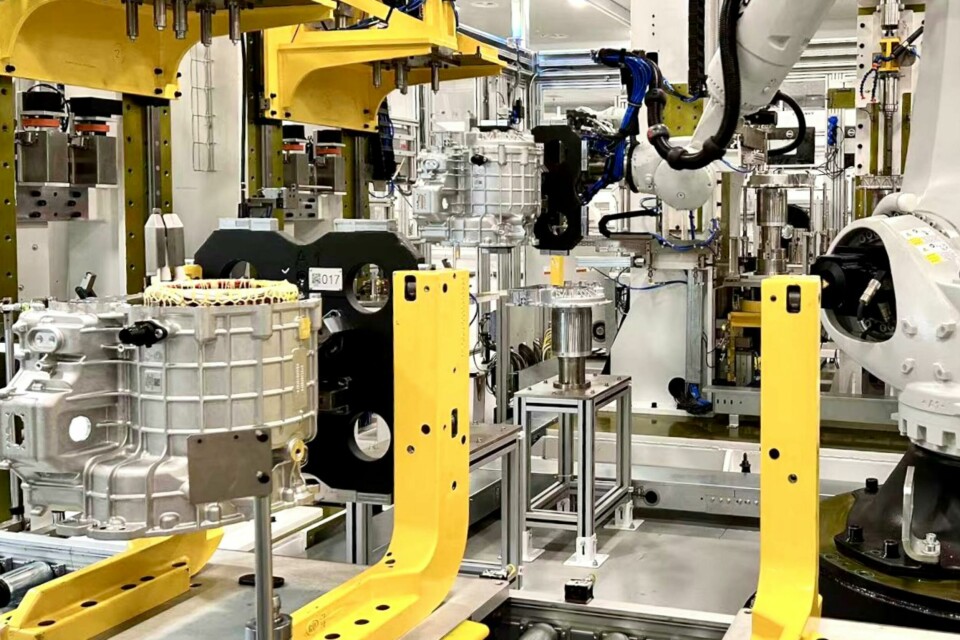

Earlier this year automation specialist Comau announced it had developed high-performance, automated production lines to assemble electric drives systems (EDS) for NIO. These included a co-production assembly line for both Induction Motor (IM) and Permanent Magnet Motors (PM), and lines for gearboxes and inverters.

However, beyond the production hardware, the project involved a very close collaboration between the two companies as they pursued a ‘simultaneous engineering approach’ which has been pivotal developing the e-motor assembly lines within very constrained timescales.

Managing the shortening product development timescales

Alan Zeng, Senior Vice President of NIO and CEO of XPT, shared some background on the project and the working partnership with Comau. “Following a challenging period for NIO the company bounced back and in 2020 commenced development work on our NT 2.0 vehicle platform. At that point our chairman had set a challenging target of 24 months to deliver the new vehicle programmes.

“Working towards this we kicked off all the projects at the same time and engaged with Comau at an early stage to discuss how we could deliver the vehicles in the shortest possible time. Comau were introduced to the new vehicle project in Sept 2021. The we began working on the processes that would reduce the time in both the product and the production line development.

“We needed to have these advanced engineering processes in place to support meeting our product delivery targets but this was then disrupted by the Covid 19 pandemic and the subsequent lockdowns, so this presented a major challenge with a lot of disruption to the supply chains and our own production operations. But we (NIO-Comau) trusted each other, and we worked on each of the challenges, one-by-one and found solutions.”

As with the OEMs, suppliers were also under a great deal of pressure during the Covid pandemic, so managing the very short project timescales around EV production presented another challenge. For NIO and Comau the solution was to adopt a simultaneous engineering approach. This would see the design and development of the production lines run in parallel with the design and development of the new products that would be produced, and this would require very close collaboration and a lot of trust between the two companies. Jeff Yuan, Comau’s Head of Countries Cluster APAC, explained how this worked.

“Normally we would start to design and develop a new production line once the vehicle’s design had been finalised and signed off by the client, but because of the very tight deadline we began to design the line with only the prototype designs for the EDS.

“Our engineers were working very closely with NIO’s R&D department, so this allowed any information on changes in the product design to be synchronised very closely with our team. This approach not only enabled us to quickly react to any changes needed in our production line system design, but also to feedback with suggestions for the product design that would minimise any challenges in the production process.”

This example of Comau working with NIO much further ‘upstream’ in the product design process that would be normally expected, reflects a wider and growing trend with equipment and materials suppliers wanting to be more involved at earlier stages in new vehicle projects to reduce impacts on development times and better optimise manufacturing solutions.

The benefits of strong partnerships

Comau had already worked with NIO on its first-generation vehicle platform, which then had a design to launch timeline of 36 months, and Zeng noted that with the shortened timescale for the EDS lines, choosing the right partner was critical. With NIO recognising Comau’s capabilities in delivering production lines, this was the obvious choice.

It’s clear that both companies have developed a high level of trust in each other, and Zeng observed that this partnership goes much deeper than the traditional client/supplier transactional relationships that are far more common across the automotive manufacturing sector.

“Normally the process involves a lot of negotiations and agreements to be finalised and contracts signed before any work commences, but we wanted to work a more in parallel way to get the project moving at the same time as the commercial processes and having worked with Comau before and both parties having that trust in each other allowed us to do this.”

EDS line – key requirements to achieve levels of efficiency and scalability

Zeng explained that the line needs to be highly flexible to produce both the IM and PM EDS variants and features high levels of automation to support high volume production. Building electric motors is very different from producing ICE engines. The e-motors are designed to operate at very high rpm, and this creates NHV issues, so the motors are built to very tight tolerances to help minimise these issues. To achieve the quality levels required is very difficult using manual assembly processes, so the line operations are more than 80% automated. Loading and unloading is fully automated, and the robots utilise a lot of camera and video systems.

When setting up a line with such a high level of automation, the calibration process can take a lot of time to complete. All the assembly processes, torque control, etc. are completely integrated, and linked together. This line only has 20 technicians working on it and has a capacity to produce 300,000 units per year.

Yuan explained that key technologies applied to this line included robotic digital simulation and robot force control and guidance. 3D intelligent guidance system and a gluing system with laser inspection and fully automated bolt delivery and tightening system.

He also highlighted an adaptable mounting plate with a zero-point positioner that would accommodate both electric motor variants.

“This supports another requirement which is not to increase the cycle time when switching between e-motor variants,” said Yuan.

Timeline for the e-motor line

The letter of intent between the two companies was signed in September 2021 with the line scheduled to start production in September 2022, 12 months later, but the partners had worked out a process of identifying any issues throughout the development process, with constant communication so as to minimise any problems once the line started production.

Comau benefited from both having worked with NIO on other projects, so having a greater understanding of the development process, and being able to leverage its wider experience and expertise in automation systems.

“For us a normal timescale to develop and install a production line of this type would be around 16-18 months. But our close partnership with NIO and our simultaneous engineering approach was very important to us meeting this tight deadline. Comau also has an extensive database of systems and components, so allowing us to react very quickly to establishing a functioning model for the new lines,” explained Yuan.

Having an established engineering team in based in China also speeded the process as they could support any changes and make quick decisions on site. Yuan noted that Comau had engineers embedded with NIO, monitoring line performance, which feeds into a monthly meeting cycle between the two companies.

NIO had designed its EDS units with a single housing design to reduce weight. Normally the EDS would be a three-piece design, featuring separate gearbox, motor and power electronic unit (PEU).

Zeng said: “So with our design the three main parts mentioned are now assembled into one housing. This is a very efficient design and has reduced the weight of the EDS. But this design restricts the space for assembly within the housing, which was another challenge.

“We also wanted to reduce the capital investment of having two lines so we focussed on developing the single line where we can switch production very quickly between the two EDS types.”

Flexible automation – challenges and solutions

Discussing the challenges of automating the assembly of an electric motor, Zeng explained that cleanliness of the line processes was very important and challenging due to the very tight tolerances of the motor parts being assembled. Also, the torque control for the bolt tightening was very important. Camera systems have been widely used for process monitoring and quality control. With the fitting of high volumes of small parts, quality is a high priority and process data is gathered and monitored across the line.

Yuan said: “We were able to leverage much of our experience and expertise in ICE powertrain production into the e-motor assembly operations. Processes such as bolt feeding and tightening had very similar requirements. Vision systems also play a big role in automating the process. In ICE production we were using 2D camera systems, but for the e-motors we now using 3D systems.”

The adapter plate with a zero-point positioner was identified as an important innovation, and Yuan also noted the application of a quick tool change system, a technology that Comau had already developed and used on ICE powertrain lines.

The rigorous quality control extends to the end of line (EOL) testing with 100% of the produced units fully tested. This is a challenging part of ICE production but what were the challenges posed by the e-motors? Zeng explained: “The e-motors have a wider range of rpm to test, up 18,000 rpm, so the systems must be capable of managing this rpm range. There is also specific testing for the gear set.”

To manage the testing of the current volume of motors there are five parallel test stations with each motor test cycle taking 3mins. But when production volume increases there is the flexibility to add more EOL test stations.

However, there is a big emphasis on the production lines being flexible not just for the existing EDS variants but also for any future products. This new EDS line is both bespoke in terms of its focus on assembly for the current EDS variants but still needs to be fit for the future, certainly in terms or ramping up production volumes.

Again, the simultaneous engineering approach looks to support this with Zeng noting that NIO XPT was sharing its future product designs with Comau in anticipation of adapting the line. “This allows us to establish which parts of the existing line, which stations, can be utilised for any new product and where changes need to be made.”

Integrating automation into production operations

NIO has 20 workers on this line, and Comau worked with them providing training on the operations and systems. This helped to speed the line’s start up and support effective quality control from the worker’s operations.

Zeng noted: “We also sent workers to Comau for training during the line’s development stage prior to installation. Although there are less direct workers on this line there is a high number indirect highly skilled technical workers associated with management and maintenance of the monitoring systems, cameras, sensors, PLC, etc. This is a major requirement for lines with this level of automation.”

Digital tools are a key enabler not only in simulating new production operations but also monitoring the production flow of ongoing manufacturing. Yuan explained that Comau had supplied the manufacturing execution system (MES) to NIO and built a digital twin of this line that runs in parallel to the physical operations. “So, we can monitor any changes in production and identify the source of any problems and we can also simulate any changes that might be planned to optimise the integration.

NIO and Comau have now gathered a lot of useful development and operational data from these new lines and along with the digital twin this will allow duplicate lines to be commissioned much faster.

Managing supply chains and planning for the future

Suppliers are also struggling to keep pace with the changes in the industry and Zeng acknowledges that this is because compared to developing and producing ICE vehicles there is greater pressure and competition to shorten the product development time and get to high volume production much faster. He also notes that the EV product lifecycle is much shorter with changing battery configurations and chemistries and EDS control systems, adding to the challenges for suppliers.

But he believes electric powertrain lifecycles become longer as technologies become more established and fixed.

“In the next few years, it will become more stable as technologies such as 800v systems come into the market. This is something many vehicle makers are working to develop. We are already in discussion with Comau to set up a third production line for an 800v product.”

The strong working partnership between NIO and Comau serves as a good example of how the automotive industry is evolving. Greater visibility upstream in the product development process and continuity in working partnerships look to provide some much-needed stability to the operational transition to EV production, and to future planning.