Exclusive: BMW Group improves efficiency with additive manufacturing gripper

BMW Group has improved the speed, versatility and sustainability of its manufacturing and cut costs by using 3D-printed bionic robot grippers. Automotive Manufacturing Solutions reports on the latest innovations from the BMW Group Additive Manufacturing Campus and manufacturing plant in Munich.

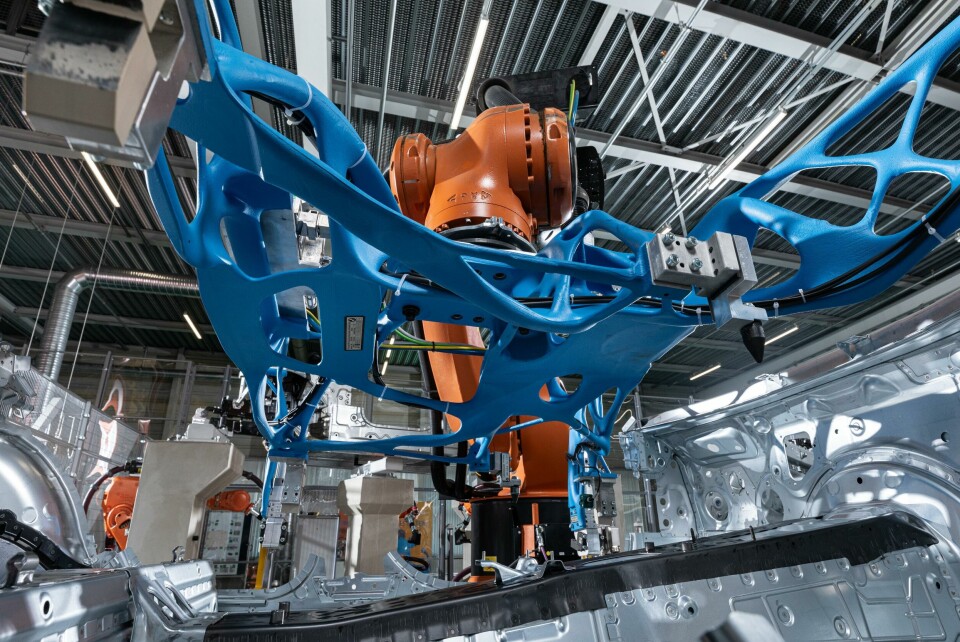

Additive manufacturing, better known as 3D printing, has been used by the carmaker for three decades, including for vehicle development, concept and prototypes, as well as for series production of specific and custom parts. But increasingly, BMW Group has been integrating additive manufacturing into its production system, including for work aids and tooling. The latest innovation is a large 3D-printed bionic robot gripper.

While BMW Group has been trialling the use of the gripper to better understand its capabilities and durability, it has been consistently improving and developing it to make it lighter, more efficient, and more versatile to suit different parts of the manufacturing process. Now, at the carmaker’s Munich plant, which builds a variety of models including the all-electric i4, the bionic robot gripper is being used to hold and move the entire floor assembly of the EV in body production.

“Why does BMW Group use additive manufacturing? The simple answer is that additive manufacturing provides significant benefits and cost savings,” Jens Ertel, head of Additive Manufacturing, BMW Group told AMS. “That means across many applications, like in the development process of our vehicles, it leads to a higher efficiency because it’s a technology that can provide parts within days, compared to several months. So, it’s a huge reduction in lead time and can save massively on tooling costs.”

“Due to the high degree of geometric freedom that the technology gives you, you can create new innovative ideas and parts and also new business models,”

To make the gripper, BMW Group uses 3D-printing to create a sand-casting mould, which is filled with liquid aluminium. With all the additional attachments the gripper weighs only 110kg, making it roughly 30% lighter than the previous conventional model used, and has intricate load-optimised structures resulting in maximum weight reduction. As a result, the robot in the body shop uses less energy compared to the previous model. BMW Group experts also suggest that ultimately it may be possible to use even smaller and lighter heavy-duty robots in the medium-term, cutting costs and emissions even further.

“We use 3D-printing to equip our established grippers with individual, printed attachments and are already replacing complete gripper systems with highly integrated and weight-optimised bearing structures,” said Markus Lehmann, head of Plant Engineering and Robotics, BMW Group Plant Munich. “When handling the full BMW i4 floor assembly, this allowed us to reduce the weight of the complete gripper by 30% and thus extend the service life of our facilities.”

In fact, it could even lead to BMW being able to use smaller, cheaper robots, helping save costs and crucial time – speeding up the larger production system and adding valued efficiency.

Innovative software and employee-led ideas

BMW has more than 200 3D-printers across its production network, decentralised across different plants. But it also centralises development, as well as additive manufacturing production at its Additive Manufacturing Campus in Oberschleißheim, in the north of Munich. Here, more than 300,000 parts were 3D-printed on industrial machines last year, with more than 100,000 parts on top printed across all the plants in the global production network.

The campus has regular exchange with the various sites to establish standards and best practice applications that can be used throughout the whole production system. At the same time, engineers and maintenance workers at each plant have the freedom to come up with innovative ideas and solutions and escalate them through 3D-printing consultants on the AMC campus and on-site contacts at each plant, and potentially even further to the campus. As well as passing on knowledge to the wider group, the campus also trains BMW employees from all over the world, working closely with those in R&D and automotive design, for example.

Ertel told AMS: “Due to the high degree of geometric freedom that the technology gives you, you can create new innovative ideas and parts and also new business models, like we’ve seen with customisations.”

As for the software, intricate and bionic structures are designed and calculated using special generative tools like Synera, which BMW iVentures has invested in. Synera, previously known as Elise, allows fast and efficient optimisation, and can virtually generate topologically optimised bionic structures. BMW said this makes it possible to exploit the full potential for lightweight construction.

Widespread uses for 3D-printed grippers

The carmaker has been trialing similar 3D-printed grippers across its plants for the past three years.

At BMW’s Lightweight Construction and Technology Centre in Landshut, the OEM has been using a large gripper element weighing around 120kg on all its robots handling carbon fiber reinforced polymer (CFRP) roofs. The gripper is manufactured in just 22 hours and can rotate 180 degrees to remove the finished roofs. Here, the new gripper is around 20% lighter than previous versions, meaning it extends the life of the robots and is more durable so cuts maintenance intervals as well as energy usage. The manufacturing of the gripper is also more sustainable, with 60% lower CO2 emissions.

The OEM is also using 3D-printed grippers in the process of chassis construction. In Plant Regensburg, the carmaker is using grippers printed using the large-scale printing (LSP) process for making doors.

Florian Riebel, head of door and flap production in Regensburg said: “With an optimised bearing structure produced using 3D printing, we were able to increase the rigidity of the gripper when handling door elements at the plant in Regensburg, while at the same time reducing weight. In subsequent projects, it is then possible to use robots with a low bearing capacity, which helps to cut costs.”

Look out for our in-depth feature from inside the campus, coming soon on AMS.