Editor's Pick – Page 7

-

Article

ArticleVIDEO: Views from the assembly line at the home of the Range Rover

Assembly workers give their reaction as Jaguar Land Rover’s Solihull plant reopens under new social distancing measures

-

Article

ArticleWatch: Kia maintains investment, launches and stability in Europe

In this video interview, Kia Motors Europe chief operating officer, Emilio Herrera, and director of marketing, Carlos Lahoz, outline how the Korean brand is learning from supply chain and production disruptions, digitalising sales channels and maintaining investment in electrification to chart a route towards recovery in Europe.

-

Article

ArticleAssembly lines begin to resume but start-stop production is the new normal

Carmakers are potentially hostage to a halting series of restarts as the automotive industry tries to gradually restart production

-

Article

ArticleBentley aims for 11 May restart at its UK factory

A comprehensive list of health protection measures will be in force as workers return to Bentley’s production line next month. The Crewe factory employs over 4,000 people working under Bentley’s strong, hand-built ethos.

-

Article

ArticleVIDEO: FCA’s return to production in Europe begins as the Sevel LCV plant reopens

After weeks under lockdown, Italy’s automotive manufacturing sector takes its first steps to recovery

-

Article

ArticleDziczek: After the pandemic, restoring component supply and customer demand will form the next hurdles

In the second of Ultima Media’s new Livestream webinars, editor-in-chief Christopher Ludwig was joined by Kristin Dziczek, vice-president of the US Center for Automotive Research (CAR), to talk about a range of issues facing the global automotive manufacturing and supply chain, and what it means for the US market…

-

Article

ArticleMofid Elkemiri, LEVC manufacturing operations and quality director

LEVC’s Mofid Elkemiri was recruited to the Geely-owned company back in 2016 as launch director for the TX5 electric taxi. Prior to that he spent six years at UK-based trim supplier CAB Automotive, where he rose to the position of engineering and quality director. AMS speaks to him about his current role, ramping up production, battery cell supply and the relationship with the parent company. But first, we ask how the factory has been affected by the recent coronavirus measures and the suspension of production…

-

Article

ArticleZipse blog sets out BMW’s response to the coronavirus crisis

As China operations resume, BMW CEO Oliver Zipse sets out the action areas to steer the company’s global production through the crisis …

-

Article

ArticleAudi mobile maintenance app keeps Ingolstadt in the know

Maintenance teams at the Ingolstadt factory have a new app on test, developed an inhouse to provide live updates from across the assembly process direct to their smartphones

-

Article

ArticleMitsubishi masterplan – spearheading Alliance activity in South-East Asia

In its new regional strategies for 2020, the Renault-Nissan-Mitsubishi Alliance announced that it wants Mitsubishi to spearhead activities in South-East Asia

-

Article

ArticleItaly’s OEMs and suppliers stay resolute through national coronavirus measures

FCA, Lamborghini, Ferrari, Maserati, Alfa Romeo Brembo and Pirelli – the famous names of the Italian automotive industry are battling on through the Covid-19 crisis

-

Article

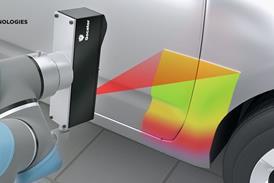

ArticleSimulate to fabricate: vehicle plants keep VR and AR in their sights

Carmakers are exploring how virtual reality and augmented reality can be used to improve manufacturing and inspection operations

-

Article

ArticleSteel makes the case as the mainstay material for vehicles

With OEMs demanding vehicle-structure materials that are low in mass, crash-protective and economic to use, steel grades stay true to form

-

Article

ArticleStrong, light and formable, stainless steel re-enters the material mix

Helsinki-based Outokumpu says stainless steels are ideal for lightweight, safety-critical structural parts and have put it to use in the series production of EV battery enclosures

-

Article

ArticleUS giants in Asia: Part 1 – down and nearly out in India

As GM and Ford scale back from the subcontinent, the withdrawal is symptomatic of their global challenges and retrenchment back in the homeland

-

Article

ArticleYour webinar questions answered: How tier 1 suppliers are responding to tough headwinds

You asked, we answer. We return to the questions from our audience that we didn’t have time to answer in our live webinar, ranging from which parts of automotive tier 1 suppliers’ business models are at risk of commodification, to how tier suppliers are changing manufacturing processes

-

Article

ArticleAMS on Africa: Part 5 – Heavy-duty headway at Scania

There may be less reliance on automation at Scania’s Johannesburg plant but flexibility and workflow keep operations in smart shape for the needs of its commercial vehicle customers

-

Article

ArticleAMS on Africa: Part 3 – Game plan for South Africa

Despite competition elsewhere in the continent, South Africa retains its key place among global manufacturing strategies

-

Article

ArticleInvesting in testing: better scrutiny for complex new vehicles

Rigorous testing of new vehicles, systems and components has become more important as complexity of the products increases and pressure to reduce time to market grows. AMS visits Test World in Finland to see some of the developments introduced to meet this demand…

-

Article

ArticleDo or die: quality and precision begins with the toolmaking

Mould and die manufacturers reveal the latest solutions deployed to ensure quality control remains paramount