Casting/Forging News

Honda looks to master flexibility to futureproof production operations

Honda North America’s newly upgraded production operations in Ohio are going to be the OEM’s template for flexible production of ICE, hybrids and EVs on a single line.

$21bn Hyundai plan to scale US automotive vehicle production

Hyundai ramps up US automotive investment with a $21bn plan to boost production, localise supply chains and advance EV and robotics technologies by 2028

Honda North America’s big investment in flexible manufacturing for EVs, hybrid and ICE vehicles

Honda invests $1 billion in retooling its Ohio manufacturing plants to build ICE, hybrid, and EV models on same production line.

Watch now: How to maximise efficiency in battery tray manufacturing and integration

This webinar showcased innovative, cost-efficient quality processes to assure 100% quality in battery manufacturing. New quality solutions from Hexagon enable automakers to detect defects efficiently and ensure a perfect fit into the underbody of the car.

100 years of Henkel in the automotive industry

Henkel celebrates 100 years: Henkel’s heritage and impact on the automotive industry, and how Henkel will shape the vehicles of the future

Watch Now: Next-Gen Gapfillers: Henkel’s Blueprint for Automotive Electronics

This webinar explored Henkel’s latest innovations in thermal gap fillers, designed specifically for automotive electronics.

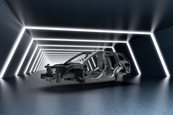

Changing dynamics– developing the next generation of vehicle architectures

Building electric vehicles has demanded big changes in OEM production operations and increased support from tier suppliers

Porsche launches all-electric Macan

Porsche will build its first Porsche models on the PPE platform at its factory in Leipzig, Germany.

Watch Now: Shaping the future: How electric vehicles are driving manufacturing decisions

Explore electric vehicle (EV) architecture design and manufacturing complexities, from flexible platforms to battery integration challenges.

The state and stipulation of automotive production: Retrospect 2023 to prospect 2024

In 2023, the automotive industry underwent a transformative journey, adapting to trends such as sustainable materials, electric vehicle dominance and digitalisation. But what clues does 2023 provide about the vehicle manufacturing landscape in 2024?

Gestamp joins Catena-X digital supply chain exchange

Parts maker Gestamp has joined the Catena-X digital platform to advance its circular economy and technological innovation

Watch: Structural change – Developing vehicle architectures optimised for EV manufacturing

Hear expert insights into the development and production of high volume electric vehicle architectures, and how these are driving innovation in manufacturing processes and efficiencies, featuring Gestamp’s North America R&D director Paul Belanger and ArcelorMittal head of automotive steel solutions Jérôme Favero.

Form and function: Developing production processes and structures for electric vehicle architectures

The new electric vehicle architectures are also continuing to evolve as vehicle makers strive to find the optimum balance between platform flexibility, while also being viable for high-volume production. To get some insights in to this ongoing process AMS spoke with Paul Belanger, Gestamp’s R&D Director for North America

Special series: Digitalising manufacturing engineering at Audi

Jörg Spindler is leading Audi’s push to virtualise production planning, ramp up battery production and use data to reduce emissions and improve productivity in areas like toolmaking and body shop

Tools for progress: real-time tracking and monitoring in Audi’s toolmaking

The carmaker’s Toolmaking 4.0 system is bringing greater visibility of suppliers and potential disruption of machines and operations at tool shops, with high productivity gains.

Stellantis to localise production of new electric drive module in Indiana

Investments to be made at Indiana Transmission, Kokomo Transmission and Kokomo Casting Plants, with the company investing a total of $155m

Dacia – building on a successful formula

Speaking to AMS, Carlos Carrinho, General Manager Dacia Vehicle plant Mioveni, discusses the factory’s unique position within the realm of European car manufacturing and how it has been continuously developing to meet future production challenges

GM invests $918m in four US powertrain production facilities

Investment will prepare four GM plants for production of 6th generation small block V8 and EV components

Material matters: body, forming and process transformation

Teknia, ArcelorMittal and SSAB joined the seventh panel at Automotive Evolution Europe to discuss how new technology and materials are ushering in new innovations in manufacturing.

Watch: Are all OEMs start-up manufacturers now?

In this livestream, learn how OEM start-ups can short time to market in manufacturing and re-engineer body structures, featuring the head of manufacturing at Volta Trucks and ArcelorMittal.