Rising labour costs become biggest concern for automotive manufacturing

Rising labour costs and skills shortages are the biggest concern for the automotive manufacturing industry this year, according to the latest AMS & ABB Automotive Manufacturing Outlook Survey 2023.

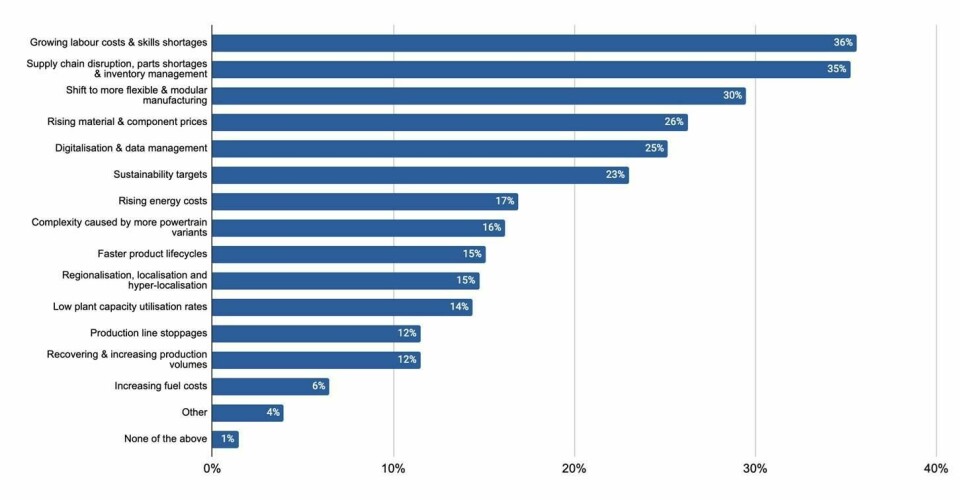

In a global survey of industry experts, more than a third of respondents (36%) said they were concerned about labour costs and the skills shortage, putting the issue at the top of the challenges the industry is facing.

In fact, labour issues overtook supply chain disruption as the most pressing obstacle for the industry, with 35% of respondents reporting disruption, parts shortages and inventory management. This is still clearly affecting a large proportion of respondents, just lagging behind labour concerns, as disruptions are ongoing with the ongoing Russia-Ukraine and Israel-Hamas conflicts, the drought on the Panama Canal, and Red Sea and Suez Canal tensions adding further levels of complexity. However, in comparison to the previous year’s survey, supply chain disruption has eased, as this was the dominant issue (67%) in 2022.

“The main challenge last year was supply chain disruption, but now that it has somehow eased and been mitigated this year, it’s been slightly overtaken as an issue,” said Daniel Harrison, automotive analyst, AMS. “As we move to more EVs, those changes mean that the skillset required in manufacturing and production lines has evolved and is gradually increasing in terms of automation skills, robotics, EV understanding, software and even AI. The skillset has fundamentally changed in comparison to the traditional skills for ICE vehicles in the past, and we’re also competing for those skilled workers at the same time.”

Of course, the past year saw labour disruption, particularly in North America, when the UAW strikes ran for weeks and hit the big three’s (GM, Ford and Stellantis) production lines and wallets, with GM reporting that the union action cost the carmaker $1.1 billion.

Rising material and component prices and rising energy costs also ranked high on the list of issues for the industry, with 26% and 17% of respondents respectively stating these as areas of concern.

The array of industry challenges have been captured in this comprehensive global survey with AMS teaming up with robotics and automation experts ABB Robotics to provide insight into the current state of play in automotive manufacturing.

Beyond automotive manufacturing and related challenges, the survey also measures the overall market sentiment around vehicle production and sales volumes, and looks to the future, exploring where the likely opportunities are likely to be.