Joining News

VW’s Bratislava and Pamplona gain strategic production value

VW ramps up production in Slovakia and Spain, shifting key models like the Passat and future EVs away from Germany to cut costs and drive innovation.

Honda North America’s big investment in flexible manufacturing for EVs, hybrid and ICE vehicles

Honda invests $1 billion in retooling its Ohio manufacturing plants to build ICE, hybrid, and EV models on same production line.

100 years of Henkel in the automotive industry

Henkel celebrates 100 years: Henkel’s heritage and impact on the automotive industry, and how Henkel will shape the vehicles of the future

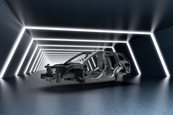

Megacasting: a new frontier or unfounded flare-up?

Megacasting claims to reimagine automotive production, reducing parts and welds significantly. But is it a one-size-fits-all solution?

Sames solves for BMW & Mercedes: Adhesive tech in bodyshop & glazing

Sames innovates with custom adhesive solutions for BMW & Mercedes, enhancing carbon fiber body assembly and glazing applications with tailored systems and rigorous testing.

Exclusive: BMW Group improves efficiency with additive manufacturing gripper

AMS visited BMW Group’s Additive Manufacturing Campus and plant in Munich to see it 3D-printed bionic robot grippers, which are saving costs and emissions and improving efficiency across its plants.

Changing dynamics– developing the next generation of vehicle architectures

Building electric vehicles has demanded big changes in OEM production operations and increased support from tier suppliers

Join DESIGN4PRODUCTION: innovating across car design and manufacturing engineering

Automotive design and manufacturing experts will share insights at Design4Production in Munich on 15 May on how to accelerate innovation, efficiency and sustainability.

Design and manufacturing integration, digitalisation key to cost and sustainability gains for BMW’s Neue Klasse

To realise large cost and emission savings on its EV architecture, BMW is redesigning vehicles and manufacturing in parallel, and rolling out rapid digital solutions.

A class of its own: transforming BMW production for next-gen EVs

BMW’s home plant will produce only EVs by 2027, with much of the century-old factory rebuilt to meet new levels of efficiency and digitalisation, without missing a beat of ongoing production.

JLR expands EV production to Slovakia

JLR has announced that it will develop its plant in Nitra, Slovakia to produce electric vehicles by 2030.

How digitalisation is ramping up battery cell production for EVs

Digitalisation is helping to scale up battery cell production in North America through improving standardisation and traceability and ensuring quality of materials.

Watch: Automated weld seam inspection of EV-battery trays with VIRO WSI

An EV battery tray typically has many welds. But even one defect weld risks stability, tightness, and safety

How Vitronic’s Weldloop software reimagines the welding process

Find out how Weldloop’s technology achieves quality enhancements in automotive welding through machine vision technology.

A friend of flexible lines – upgrading JLR production for EVs and more

Barbara Bergmeier is driving digitalisation, sustainability and resilience across operations, and wants to ramp up EV manufacturing whilst staying flexible

Form and function: Developing production processes and structures for electric vehicle architectures

The new electric vehicle architectures are also continuing to evolve as vehicle makers strive to find the optimum balance between platform flexibility, while also being viable for high-volume production. To get some insights in to this ongoing process AMS spoke with Paul Belanger, Gestamp’s R&D Director for North America

Automotive ADAS Camera White Paper

The advanced driver assistance systems (ADAS) utilized in today’s automobiles are built using active alignment, a cutting-edge assembly technique used to produce high-quality camera modules. Henkel’s cutting-edge dual-cure Active Alignment Adhesives ensure reliable, fast bonding while achieving optimal lens alignment in these safety-critical modules.

AMS Evolution Munich – Building Europe’s EV production network

Building battery gigafactories and updating existing plants are key in ensuring Europe will become an EV production powerhouse

Material matters: body, forming and process transformation

Teknia, ArcelorMittal and SSAB joined the seventh panel at Automotive Evolution Europe to discuss how new technology and materials are ushering in new innovations in manufacturing.

Henkel Adhesives grips tight to growth through EV battery innovation

With a focus on research, Henkel has joined automakers and battery producers in the pursuit of better EVs through hard-won scientific advances.