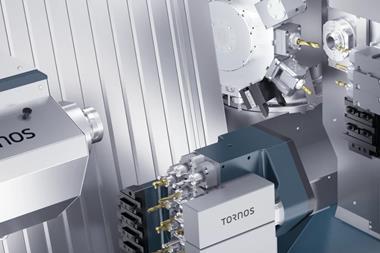

Polydec’s operations producing small, high-precision components rely heavily on more than 30 Deco, EvoDeco and SwissNano machines from Tornos

More than 50% of the world’s automobiles contain parts that were manufactured in the Swiss town of Biel/Bienne by Polydec SA. Although the municipality is best known for watchmaking, and home to the head offices of some of the great global brands, Biel/Bienne can also look back on a long history in the automotive sector. Cars were made there as far back as 1889, and from the 1950s onwards, tens of thousands of vehicles for consumers all across Europe have been produced in the town by General Motors. Biel/Bienne continued its success story with Claude Konrad, head of Polydec SA, a manufacturer that largely relies on over 30 Deco, EvoDeco and SwissNano Tornos machines.

More than 50% of the world’s automobiles contain parts that were manufactured in the Swiss town of Biel/Bienne by Polydec SA. Although the municipality is best known for watchmaking, and home to the head offices of some of the great global brands, Biel/Bienne can also look back on a long history in the automotive sector. Cars were made there as far back as 1889, and from the 1950s onwards, tens of thousands of vehicles for consumers all across Europe have been produced in the town by General Motors. Biel/Bienne continued its success story with Claude Konrad, head of Polydec SA, a manufacturer that largely relies on over 30 Deco, EvoDeco and SwissNano Tornos machines.

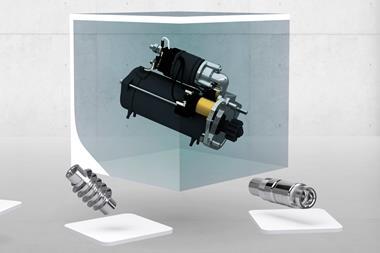

As a subcontractor specialising in the production of small, high-precision components, Polydec SA manufactures around 40m parts per month, especially for the watchmaking, medical and automobile industries. For the latter, more than 20m shafts for dashboards and fuel injection systems are produced in Polydec’s workshops each month. To date, the company has produced more than five and a half billion parts in Biel/Bienne.

Automobiles and Biel/Bienne: a long success storyAlthough Henriod Frères had been producing cars in Biel/Bienne since the 1880s, the golden age of this sector began some decades later. On February 5th, 1936, an eight-cylinder Buick rolled off the production line at General Motors. In the same year, 321 Chevrolet, 115 Buick, 61 Oldsmobile, 36 La Salle, 117 Vauxhall, and 318 Opel cars were produced. When Henriod Frères closed down in 1975, as many as 329,864 vehicles had been produced in Biel/Bienne.

In 1985, Polydec SA was founded and in 1998 it got the QS:9000 certification for the automobile industry. Today, the company’s expertise is recognised far and wide and Polydec SA is one of the very few suppliers of parts for actuators (micro motors) that are used for dashboards.

In 1999, Polydec invested in its first Deco 10 machine. It turned out to be a good strategic choice and further machines followed. This first Deco is still active today in a workshop equipped with one EvoDeco and 12 SwissNano machines. For the oldest machines, a revision programme is underway. For other workpiece types, the manufacturer has an inventory of about 40 Escomatic machines.

As far as metal cutting is concerned, Polydec SA is pushing the envelope and recently the company machined steel parts with diameters down to 0.07mm (the diameter of a human hair) and a length of 0.3mm. The parts are then polished and quenched. Polydec SA regularly processes workpieces of 0.3mm diameter that demand a number of machining processes, such as drilling or polygon cutting. Konrad explains: “When we reach such dimensions, the mechanical system no longer reacts normally and the cutting speed is virtually zero.” He adds: “On a regular basis, we are producing to tolerances of ±2 μ and, in extreme cases, we even have to go down to ±1 μ.”

SwissNano at the service of precisionAfter one year of testing, the first SwissNano was assessed as being highly efficient and the company soon ordered 11 additional machines. “We are extremely happy with this small machine; not only is it equipped with state-of-the-art technologies – to name just the spindle motor – but it has also a compact design that enables it to easily fit into every workshop. Furthermore, its precision is really excellent,” states Conrad.

What do you think of SwissNano’s ergonomics?It boasts an appealing design, perfect visibility and very good accessibility. I had to get used to the machine, the available space is a bit confined for an operator who used to work with Deco machines. Of course, it’s not possible even for SwissNano machines to be very compact and offer a vast machining area at the same time. Today, I enjoy working with this machine. They are well enclosed, tight and very clean.

Do you carry out particular operations?We carry out all turning and gear cutting operations on it. The asset of this machine is definitely the quality level that we can achieve. This is remarkable for a machine with such a small footprint. We also performed some stamping work but this machine has not been designed for such operations.

And what about service?On the whole, we are satisfied with our relationship with Tornos and the aftersales service. As for SwissNano, I can’t comment on the service because in three years of using this machine, it hasn’t been necessary to call aftersales service.

…to offer unparalleled servicesBy combining its technical, people and administrative skills, Polydec SA is capable of sharing its entire know-how with all its fields of activity. “The watchmaking sector is in the process of radically changing its approach towards metal cutting,” says Conrad. “Many experts from the automotive sector are now working in the watchmaking division and, here, they introduce strict methods that may deter anyone who is not familiar with them.”

He adds: “In the automotive sector, there are extreme cases in which we have to deliver parts with a reject rate of zero ppm, ie. we have to ensure that not even a single part of 1m supplied parts is out of tolerance. For this purpose, we have installed automatic inspection systems that enable us to subject all of the parts to an extensive inspection.”

Where humans make the differenceThe company offers its expertise gained in automotive and other industries but this is not enough. Every field has its own constraints, for example, in terms of finishing and visual or dimensional inspection. “When talking about micron accuracy, the measuring devices are reaching their limits. So, we have to adapt ourselves to the needs and requirements of our customers,” the CEO explains.

Know-how is a prerequisite for Swiss companies to stand out and to secure jobs in Switzerland and the company’s staff are key to this. “Our customers are very demanding and we know that an average performance in most cases is not sufficient; we cannot afford mediocrity. Our challenge is to create favourable framework conditions for our colleagues to be able to support this philosophy. It is not uncommon that ‘little geniuses’ from Polydec find innovative solutions for customers and the customers cannot understand how it is possible to realise machining with such levels of performance,” he concludes. Microtechnology, made in Biel/Bienne, never ceases to amaze.