All Composites articles – Page 4

-

Article

ArticleCollective thinking

Closer collaboration between product development and production teams could lead to significant improvements in vehicle manufacturing processes. Ford Otosan holds a unique position. Michael Nash reports The scenery in Turkey is full of surprises. A quick car journey can lead to towering mountains, pristine beaches and lush forests, while historical ...

-

Article

ArticleRobots on the rise

Advances in robotics go hand in hand with new approaches to automotive manufacturing, writes Chris PickeringThe automotive industry is at a crossroads. Ahead lays the most radical shake-up in a generation, with disruptive trends such as electrification, autonomous driving and lightweight materials bringing opportunity and uncertainty in equal measure. It ...

-

Article

ArticleThe wonder material

A number of composite automotive parts enhanced with graphene were on show at JEC World in March this year. James Bakewell investigates if this material has a real place in the automotive industryFew of us would imagine that you can win a Nobel Prize for Physics by playing with sticky ...

-

Article

ArticleZoltek expands carbon fibre plant

Hungary - The company has announced that it is increasing carbon fibre production by 50% at its facility in Nyergesújfalu. As a result, the plant will have an annual capacity of 15,000 tons.The expansion will cost around US$130m, and will generate 350 additional jobs. According to Yoshihiro Takeuchi, CEO, COO ...

-

Article

ArticleWeighing up the options

Disruptive technology was high on the agenda at JEC World, the composites industry’s flagship event held every March in Paris, France.A sizable proportion of the 42,445 people who attended the show flocked to see Dirk Ahlborn, Chief Executive Officer of Hyperloop Transportation Technologies (HTT), lay out his vision for the ...

-

Article

ArticleMagna opens new composites facility

Germany - The new Composites Center of Excellence will act as a base for the development of various vehicle structural components such as subframes, as well as exterior body parts like door panels and hoods. The idea is to identify production-ready lightweight solutions that will help vehicle manufacturers meet increasingly ...

-

Article

ArticleAlto teor de fibra

Os compósitos reforçados com fibras de vidro têm sido utilizados na produção em massa de peças pendulares e parafusadas durante décadas. A AMS analisa algumas inovações recentes.A pressão de montagem sobre os OEMs para reduzir o peso de seus veículos significa que os fornecedores de materiais e sistemistas que fabricam ...

-

Article

ArticleContando com os dados

A implementação de ferramentas digitais está transformando os processos de controle de qualidade nas operações de fabricaçãoOs gabaritos físicos agora estão sendo processados como modelos digitais e a Audi diz que está no caminho para representar um conceito que reside no mundo digital "virtual". A empresa agora está explorando o ...

-

Article

ArticleAlto contenido en fibra

Llevamos décadas utilizando materiales compuestos con fibras de vidrio en la producción en masa – AMS analiza las últimas innovacionesCada vez es mayor la presión de reducir el peso de los vehículos, lo que significa que los proveedores de materiales que producen paneles de carrocería, interiores, ensamblados, etc. tienen que ...

-

Article

ArticleContando con los datos

La implementación de las herramientas digitales está transformando los procesos de control de calidad en las operaciones de producciónLos planos se generan primero como modelos digitales y Audi asegura que ya está desarrollando un concepto que reside en el mundo digital, 'virtual'. La marca explora ahora el concepto de ‘plantillas ...

-

Article

ArticleThe case for carbon fibre

The launch of the i3 has changed the conversation about the future application of carbon fibre in vehicle structures

-

Article

ArticleSeeing things clearly

AMS reports on the most recent developments in the use of machine vision technology for quality control applications in automotive manufacturingIn response to rapid and sustained improvements in machine vision technologies, a growing number of automotive manufacturing OEMs and suppliers are now deploying such systems in a wider range of ...

-

Article

ArticleCounting on the data

The implementation of digital tools is transforming the quality control processes in manufacturing operationsPhysical jigs are now being rendered as digital models and Audi says it is well on the way to representing a concept that resides in the digital, ‘virtual’ world. The company is now exploiting the concept of ...

-

Article

ArticleHigh fibre content

Composites reinforced with glass fibres have been used in the mass-production of hang- and bolt-on parts for decades – AMS looks at some recent innovationsMounting pressure on OEMs to reduce the weight of their vehicles means that material and tier suppliers making body panels, interior parts, under-the-bonnet parts, suspension assemblies ...

-

Article

ArticleBMW divests stake in carbon-fibre supplier

Germany – SGL Carbon SE will acquire the OEM’s 49% share in SGL ACF, comprising SGL Automotive Carbon Fibers (Germany) and SGL Automotive Carbon Fibers (US), according to an agreement signed in late November. BMW said the company would remain a key supplier, with procurement for the i3 and i8 ...

-

Article

ArticleSeating plan

Adient CTO Detlef Juerss talks to AMS about the company’s sure and steady approach to new and complex challengesAmong all the exhibits at the IAA international motor show in Frankfurt, a seat that Adient produces for the BMW 7-Series ably exemplifies a modern automotive manufacturing challenge – to combine precision ...

-

Article

ArticlePenn Engineering ebook: Automotive triangle of disruption

Automotive triangle of disruption – an e-book by Penn EngineeringThere is an automotive revolution in process that will change the face of the industry by 2030. Notably there are four technology mega trends driving these changes. Each of these trends create challenges for the automotive manufacturing industry in the way ...

-

Article

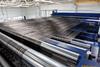

Composites take shape

Pressing and forming technology for composite materials are a key part of modern automotive production. Andrew Williams looks at the latest developmentsWhen manufacturing composite parts, companies throughout the automotive supply chain commonly rely on hydraulic press systems, which are generally far better at increasing the curing time of materials compared ...

-

Article

ArticleSelf-clinching fasteners for composites and plastics

The VariMount fastening system allows the use of PEM self-clinching fasteners for attachment applications in composites, plastics, metal and any rigid material or panel, claims PennEngineering. The company says the system integrates a self-clinching nut, stud, or standoff pre-installed permanently into a steel or stainless steel base plate.The base plate ...

-

Article

ArticleThe strength-ductility trade-off

High-strength, ductile steels could be processed on an industrial scale thanks to a new research project from WMG at the University of Warwick in the UK. AMS finds out what it means for the automotive industryThe team at WMG claim to have found a way of controlling undesired brittle stages ...