All Composites articles – Page 8

-

Article

ArticleHigh-strength steel: Strong, lightweight & cost effective

SSAB discusses the benefits of using advanced high-strength steel in vehicle structures “When it comes to cost efficiency, environmental issues and value for money, nothing can compete with advanced-high strength steel [AHSS]. The only problem we have today is that our top product could probably use a more sexy image”. ...

-

Article

ArticleInterview: John Pacanovsky, Scigrip

As the use of composites increases in the automotive industry, the head of R&D at an adhesives supplier talks about the advantages of this type of bondingAMS: Scigrip does some work with Renault and Fiat trucks, is that correct?John Pacanovsky (JP): Whilst we can’t name specific models, Scigrip is a ...

-

Article

ArticleHandling with care

New materials and the drive for greater flexibility in production have created new challenges in handlingWalk through almost any modern automotive assembly plant and the major trends in automotive assembly aren’t difficult to spot. Equally clear to see are the tensions and trade-offs that exist between them. The inexorable march ...

-

Article

ArticleMoulding tools for the future

What visitors to EuroMold 2013 can expect at the mould-making and tooling expo in Frankfurt this DecemberThe programme for 2013Exhibitors with automotive interestsAs the world trade fair for mould-making and tooling design and development, EuroMold brings together buyers, suppliers and process experts from all parts of the globe. This year’s ...

-

Article

ArticleFord makes the most of recyclate

With vehicle-makers taking a greater interest in using recycled materials, Ruari McCallion investigates the processes and challenges involvedFord Motor Company’s new F-150 trucks have been the target of some criticism for their size, weight and thirst, but according to the OEM the model will feature unprecedented levels of environmentally-friendly materials.Recycling ...

-

Article

ArticlePotential for aluminium in high volume

When, at a demonstration of the new Range Rover Sport, the presenter talked about it being in excess of 25% stiffer than its predecessor, the point was made by forcing the vehicle’s front right wheel off the ground, tilting the whole thing across its diagonal axis and banging it back ...

-

Article

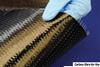

ArticleComposites come of age

BMW, Ford and Renault are incorporating composites and plastics in new modelsTo demonstrate that reduced weight and increased fuel efficiency are boosting the use of composites beyond their traditional use in niche manufacturing, look no further than BMW’s use of composites in its new i-series models; Ford’s inclusion of integrated ...

-

Article

ArticleMass is the driver for composites

Though tooling costs and shorter production runs bring advantages, reduced mass is pushing developmentCompared to steel or aluminium body structures the number one advantage of composites is mass reduction. “That is really the single most important driving factor that is leading to the drive to include more composites,” says Will ...

-

Article

ArticleFibre is in fashion

Once the domain of high-performance sports cars, recent developments have increased composite use in high volume manufacturingThere are two very distinct parts of the automotive industry; those two sectors have vastly differing challenges and have approached the use of composites in differing ways. We are, of course talking about the ...

-

Article

ArticleLearn the hard way

With so many hard part machining applications in the automotive sector, keeping up with the latest manufacturing technologies is imperative.Around 55% of applications for PCBN (polycrystalline cubic boron nitride) cutting tools are in the automotive sector – gears, shafts, CV joints, injector nozzles, bearings, extrusion dies and pressure rolls, to ...

-

Article

ArticleThe heat is always on

Steed Webzell reviews the welding technologies prevalent in the automotive arena today, as well as those currently building momentumLaser welding is popular for applications such as producing tailored welded blanks, largely because it is very effective at joining together steel sheets of varying thicknesses and strengths. Another popular application area ...

-

Article

ArticleA world of welding

Steed Webzell reveals the high levels of innovation being applied to welding processes in automotive manufacturingWelding remains the dominant joining technology for the automotive manufacturing sector but developments in technology, equipment, quality control and automation are crucial to evolving more efficient processes to produce ever lighter and stronger compOnents and ...

-

Article

ArticleA Formula One finish for the road

Ron Dennis and the birth of the chrome racecarProduction paint for road supercarsClean and open paintshop designPartnering for optimum colour consistencyAdvanced booth design and low bake ovensChrome paint on road carsAkzoNobel won the contract to supply paint for McLaren road cars partly through its experience with the chrome finish on ...

-

Article

ArticleEditor's Note: Evolution not revolution

When following the fast moving developments in this industry it’s easy to get swept along on a tide of innovative technologies, expanding (and shrinking) manufacturing networks and staggering production figures (usually from China). But, taking time to stand back and view this constant flow information, you realize that change, while ...

-

Article

ArticleCrossing boundaries at Hannover

Intelligent networked systems, composites and nanotechnology will be among the many new technologies being exhibited at Hannover Messe 2013 from April 8-12The lead theme for the 2013 Hannover Show is one of ‘Integrated Industry,’ with the event structured to reflect the increasing integration of all areas of manufacturing. Central to ...

-

Article

ArticleSheets ahead

Malcolm Wheatley reports on how advanced production processes have enabled automotive glass to be augmented with added-value technologiesFor the most part, glass alone does not provide the capabilities that a driver most values in a vehicle’s glass components. Instead, from road noise reduction to heat-reflective capabilities, and from built-in antennae ...

-

Article

Adhesive solution for DCPD bonding

SCIGRIP has launched an enhanced product for bonding dicyclopentadiene (DCPD) composites. The company claims that different grades of DCPD can be adhered successfully using SG600 without the need for time-consuming preparation techniques such as flame treatment.SG600 is cold curing and also features ratio-adjustable cure times and rheology compatible with robotic ...

-

Article

ArticlePlastics evolution

Lightweight and strong, plastic composites are increasingly used in automotive manufacturing but is Henry Ford’s all-plastic car concept coming any nearer to reality, asks Malcolm WheatleyLocated in a leafy suburb of the Canadian capital of Ottawa, the country’s National Research Council (NRC) is one of the world’s premier scientific and ...

-

Article

ArticleForming a bond to replace spot welding

Sticky timesBody strengthBetter applicationUsing adhesives for body manufacture – adhesives which can be formulated for aluminium, steel and composite bonding applications on unprepared surfaces – is a trend that’s on the rise with automakers,” sums up Jeff Kapp, a structural adhesives specialist within 3M’s automotive division. “Some manufacturers have been ...

-

Article

ArticleJoined-up thinking at Fronius conference

Industry expertsComplex casingsLow volume approachGlobal production processesDelta spot weldingQuality controlFronius recently held its annual international conference, and this year’s topic was 'Demands of joining technology for modern vehicle makers'. The Austrian company’s close working relationship with major OEMs was apparent from the number and quality of speakers present. All those ...