All Battery System and Pack Production articles – Page 12

-

News

NewsAudi-FAW to construct new EV plant in China to meet growing demand

Audi plans to begin construction on a new plant in China for fully electric Audi models, set to be completed by the end of 2024.

-

News

NewsAMS EVolution summit returns with fresh new format and guest speakers

The Automotive Manufacturing Solutions EVolution Summit returns this spring from 17th - 19th May with a brand-new format and with a mission to provide unique and exclusive insight into the world of automotive production.

-

News

NewsToyota to expand US manufacturing capacity with $90m investment in North American plants

Toyota has announced an additional $90m investment in two US manufacturing facilities to expand hybrid transaxle and engine capacity for electric vehicles.

-

News

NewsVolvo investing $1.1 billion in Gothenburg site to support huge electrification push

In the coming years, Volvo Cars will be investing SEK 10 billion ($1.1 billion) into its manufacturing plant in the Torslanda province of Gothenburg, Sweden, as preparation for the production of the next generation of fully electric cars.

-

News

NewsVolvo and Northvolt agree to build new gigafactory in Sweden

Volvo Cars and EV battery manufacturer Northvolt have announced a new joint battery manufacturing plant will be built in Gothenburg, western Sweden.

-

Article

ArticleBritishvolt and Glencore agree to expand battery recycling capacity in the UK

Britishvolt has announced a joint venture with strategic partner Glencore to build a battery recycling ecosystem in the UK.

-

News

NewsMazda resumes US production with new all-electric CX-50 SUV rollout at Alabama factory

The first 2023 CX-50 SUV has rolled off Mazda’s new Huntsville assembly line, marking the Japanese carmaker’s return to US-based manufacturing following a 10-year hiatus.

-

Article

ArticleBritishvolt signs agreement with Lotus to expand battery cell production for electric sports car

Britishvolt has signed a Memorandum of Understanding (MoU) with Lotus to advance lithium-ion battery cells and support the British EV car manufacturers brand targets and vehicle performance objectives.

-

News

NewsGM announces $6.6 billion investment in Michigan EV and battery production

General Motors has announced $6.6 billion worth of investment across Michigan to construct a new manufacturing plant and develop EV pickup production.

-

News

NewsBritishvolt and UKBIC sign agreement to develop next generation cell technologies

Britishvolt has signed a two-year, multi-million-pound agreement with the UK Battery Industrialisation Centre (UKBIC) to develop next-generation battery cell technologies.

-

Article

ArticleStrategies for a European battery supply chain

Battery manufacturing experts from ACC, Dräxlmeier and Rockwell Automation discuss the changes underway in the European battery supply chain, and what is needed to be done to secure production and supply for the automotive industry.

-

News

NewsBritishvolt receives UK government support for Northumberland EV battery plant as sustainability goals drive localised manufacturing

The British government has confirmed it will fund the creation of an electric vehicle battery plant in Northumberland.

-

News

NewsVinFast invests in StoreDot extreme fast charge battery cell development

StoreDot’s Series D funding round will be up to $80m and the capital will be used for completion of R&D and mass production scale-up of silicon dominant extreme fast charging (XFC) battery cells by 2024

-

Article

ArticleAMS Paintshop 2022 – Paint it Green

In this edition we get insights into how OEMs are adapting and developing their paintshop operations and processes to meet the need for more efficient and sustainable production, as well as insight into scaling up battery production

-

Article

ArticleThe leaders of the pack

Producing battery enclosures and packs is an important part of EV assembly, and manufacturers are focused on better standardising and inspecting parts to improve automation and quality. Jason Dunn reports from the AMS Evolution Summit held online in December

-

Article

ArticleAn electric shock to the system

Italvolt founder Lars Carlstrom has a mission to scale up EV battery production in Europe with a new factory in Italy – and a blueprint for scaling up gigafactory development. He speaks to Christopher Ludwig and Daniel Harrison

-

Video

VideoElectrifying heavy truck production at Scania

Plant general manager Mathias Wijkström discusses the process, technology and planning considerations as Scania starts production of battery electric trucks

-

Video

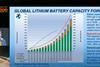

VideoGlobal powertrain and battery production forecast: ever-evolving complexity

With diverging regulations, infrastructure, market trends and manufacturing bases, the path to EV and battery production will vary across regions, adding more variation for OEMs and suppliers. Ultima Media analyst Daniel Harrison shares the latest data on powertrain and battery forecasts

-

Video

VideoGetting giga with it – ramping up battery cell production

Manufacturers require huge investment and must carefully consider production locations and technology to build batteries at ‘giga scale’, reveal leaders from Italvolt, AMTE Power and Zeiss

-

Video

VideoScaling battery pack production

Increasing production of battery enclosures at scale will be essential to launching EVs in line with targets. ABB’s Patrick Matthews and Zeiss’s Paulo Cruz discuss automation and quality control opportunities.