In the coming years, Volvo Cars will be investing SEK 10 billion ($1.1 billion) into its manufacturing plant in the Torslanda province of Gothenburg, Sweden, as preparation for the production of the next generation of fully electric cars.

As part of the planned investments, the company will introduce several new and more sustainable technologies and manufacturing processes in the plant. These include the introduction of megacasting of aluminium body parts, a new battery assembly plant and fully refurbished paint and final assembly shops.

This follows a recent announcement by Volvo Cars and Northvolt, the leading battery cell company, to invest SEK 30 billion in the development and manufacturing of batteries for the next generation of pure electric Volvo models.

Both investment plans represent new steps towards Volvo Cars’ ambition to be a fully electric car company by 2030 as well as localised production in the company’s hometown.

“Torslanda is our largest plant and will play a crucial role in our ongoing transformation as we move towards becoming a pure electric car maker by 2030,” said Håkan Samuelsson, Volvo chief executive.

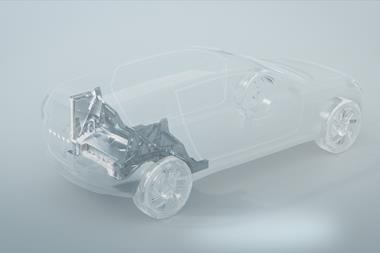

The introduction of megacasting of aluminium body parts for the next generation of electric Volvo models is the most significant change introduced in the investment package, the company noted.

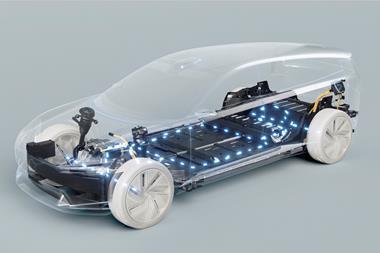

Megacasting is the process of producing a single large aluminium body instead of welding together many smaller parts. It’s a process that is still relatively uncommon in automotive manufacturing but allows for a number of benefits in terms of sustainability, cost and car performance during the vehicle lifetime.

Casting major parts of the car’s floor structure as one single aluminium part reduces weight, improving the energy efficiency and thereby the car’s electric range. Volvo designers can then optimally use the available space inside the cabin and luggage area, boosting the overall versatility of the model.

Megacasting also reduces the complexity of the manufacturing process. In turn, this creates cost savings in terms of material use and logistics, reducing the overall environmental footprint across the manufacturing and supply chain networks.

Ambitious restructuring

These investment plans all constitute essential aspects of a broader electrification strategy for Volvo.

“We will introduce a new electric vehicle platform around 2025, and for this, we will use an aluminium casting for the rear floor section of the vehicle,” explains Mikael Fermér, solution architect for vehicle platforms at Volvo Cars, in an interview with AMS.

Fermér, who has spent around 25 years at Volvo and Geely, mostly in body structure engineering, said it makes sense to “focus the development and use of the megacast parts in this part of the body since it is a ‘busy’ area of the vehicle in terms of seating, suspension, powertrain configurations.”

In addition, as the company moves away from steel to cast aluminium, there are reductions in CO2 emissions in sourcing the material. For example, Volvo expects the megacast parts to be 15-20% lighter than a steel floor.

The investments in Torslanda and the new megacasting process are huge endeavours. But Volvo sees this as a necessary step to securing future EV development and production. While the cost is high, Fermér described it as a “long lifetime” investment – and one that will further support many new lifecycles of electric vehicles.

The installation of new machinery and implementing new processes will also be required with an updated paintshop, which will support the ongoing reduction of paint shop energy consumption and emissions.

A new battery assembly plant will integrate battery cells and modules in the car’s floor structure, as the assembly shop is being refurbished to accommodate next-generation fully electric cars.

The Torslanda plant, which has an annual production capacity of 300,000 cars and is one of Volvo Cars’ longest-operating manufacturing facilities, will also refurbish its logistics operations. The company will also invest in facilities surrounding the plant, such as break areas, locker rooms and offices, to improve the working environment.

Topics

- Aluminium

- Assembly

- Battery System and Pack Production

- Electrification

- Europe

- EV manufacturing

- Industry 4 and Smart Factory

- Kaizen

- Lean manufacturing

- Lightweighting

- Logistics

- Materials

- Materials

- Northvolt

- OEMs

- Paintshop

- Plant Functions

- Powertrain

- Powertrain

- Process Improvement

- Regions

- Steel

- Suppliers

- Sustainable production

- Volvo Cars

No comments yet