The die is cast for Volvo’s future EV production

One of the key pillars of Volvo’s investment in electric vehicles will be the application of aluminium megacasting to produce large structural parts. Mikael Fermér, solution architect for vehicle platforms at Volvo Cars, explains the significance of this change for EV production.

Last year Volvo Cars announced its intention to become a ‘pure electric carmaker by 2030’, with plans for 50% of its sales to be EVs by 2025 and 100% by the end of the decade. Now, the full scale and impact of this transition for the Geely-owned carmaker’s manufacturing and supply chain are becoming increasingly evident, with multi-billion-dollar investments and significant upgrades to production equipment, partnerships and facilities.

The carmaker has recently announced a SEK 30 billion ($3.3 billion) investment as part of a joint venture with Swedish battery cell startup Northvolt to build a lithium-ion battery R&D centre and gigafactory close to its main plant in Torslanda, near Gothenburg, Sweden, which will start production by 2025. Volvo Cars will invest a further SEK 10 billion to modernise the Torslanda plant for the next generation of EV production, including a new battery pack assembly facility, and upgrades to paint, logistics and vehicle assembly areas at the plant.

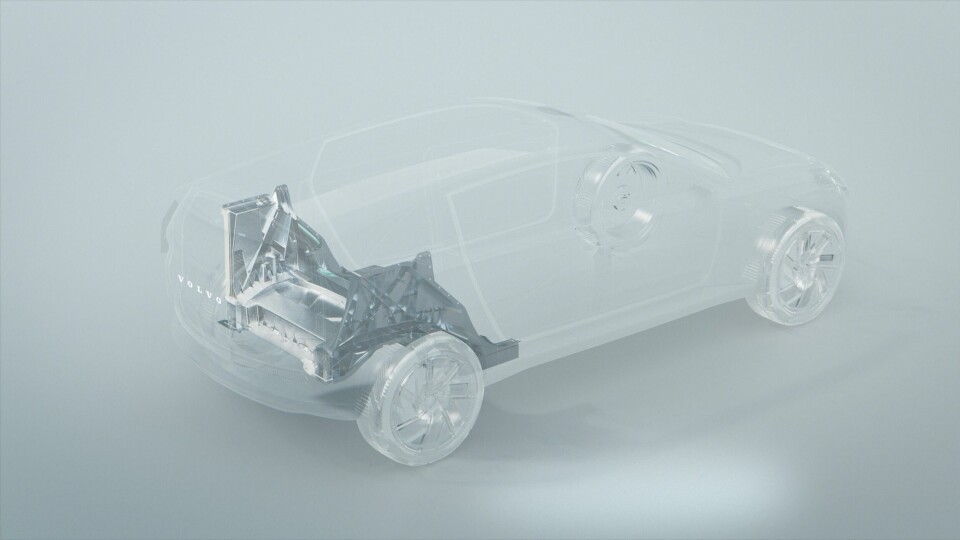

These investments will be critical to producing electric vehicles that are more competitive, have better performance and generate fewer CO2 emissions across their manufacture and supply chains. One the biggest changes evident for Volvo’s engineering and manufacturing will be the use of large, cast aluminium floor sections, produced using a relatively new ‘megacasting’ process, which will be rolled out first at the Torslanda plant.

Megacasting is the process of producing a single large aluminium body instead of welding together many smaller parts. It’s a process that is still relatively uncommon in automotive manufacturing – at least for large, structural parts – with the notable exception of Tesla.

Volvo Cars will use megacasting for the rear floor section of a new EV platform as this part of the body contains many parts related to seating, suspension and powertrain configurations

The use of this process will now underpin future model development and production at Volvo. The megacast parts will be used in the rear floor section of vehicles in a new vehicle platform, according to solutions architect for vehicle platforms at Volvo, Mikael Fermér, who points to ways this change will improve production processes, increase flexibility, reduce logistics costs and emissions – while also allowing more flexibility in vehicle development.

“We will introduce a new electric vehicle platform around 2025 and for this we will use an aluminium casting for the rear floor section of the vehicle,” explains Fermér, who has spent around 25 years at Volvo and Geely, mostly in body structure engineering. “This makes sense to focus the development and use of the megacast parts in this part of the body, since it is a ‘busy’ area of the vehicle in terms of seating, suspension, powertrain configurations.”

In opting to use megacasting, Volvo is committing to a high level of investment in technology, equipment and infrastructure at Torslanda, not least the establishment of an aluminium foundry at the site, which will reportedly have an annual capacity of 55,000 tonnes. The casting equipment itself occupies a large footprint; according to Fermér each are around 20 meters long, six meters wide and six meters high, and have a cycle time of around 140 seconds per floor, so the plant will need several units to produce parts in volume. Fermér says that the carmaker is in discussion with suppliers in Europe and China to buy this equipment.

Volvo will eventually introduce megacasting at all plants where the new EV platform is produced.

Volvo Cars solutions architect for vehicle platforms says megacasting will allow Volvo to engineer optmal floor layouts for completely different body sizes on the same platform

A way to be mega flexible

As the transition to producing electric vehicles requires huge investments in cash and resources, vehicle makers are focused on maximising this expenditure over the longer term. To that end, adapting vehicle platforms to meet inevitable changes in technologies and market trends will be a key priority. Fermér believes that megacasting offers a viable solution.

“If you take a traditional platform, you are deciding from the start to optimise its flexibility in terms of vehicle length, width, height, seating options, powertrains, etc. So, everything is pre-defined and as soon as you launch that platform it starts to get ‘old’. This is not the case with the planned megacast parts.”

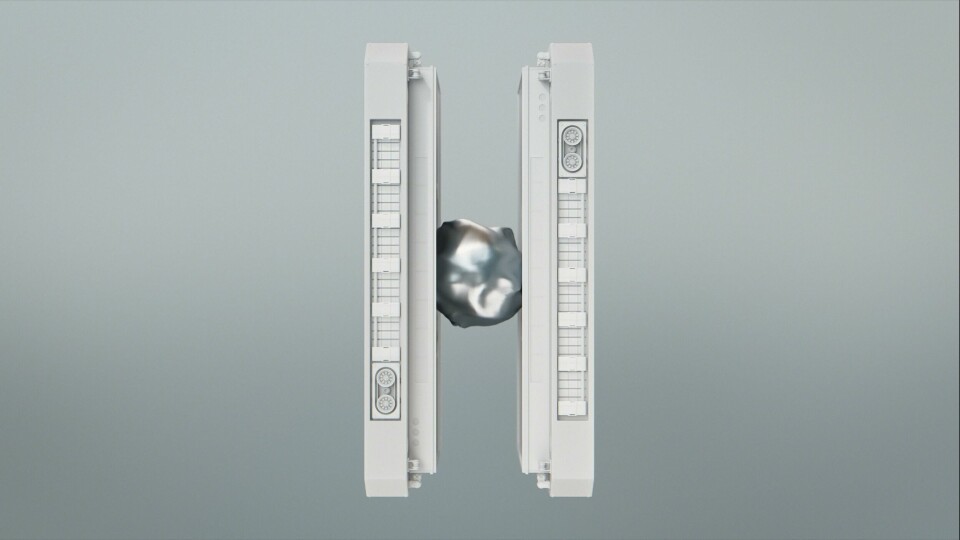

For example, a megacast floor can be optimised for a small, B-segment car with no rear electric motor and a simple suspension layout. At the other end of the scale, a manufacturer can use megacasting for the floor of a seven-seater with three seat rows and full active suspension, engineering the floor for this product in a completely different way to other segments on the same platform.

“Attempting to design a single platform that will cater for a range of models will require compromises, but megacasting allows you to produce dedicated floors for each product,” says Fermér.

He adds that the duty cycle of the casting dies – which is around 100,000 cycles – offers the opportunity to fine tune dies to get better output or adjust to improve performance or adapt to updated technology, such as electric motors and batteries. “This is very useful as there are likely to be some big technology shifts and this process allows you follow these changes, whereas this would be more difficult with a traditional platform,” Fermér adds.

Consolidating parts, logistics, scrap and emissions

Despite its high cost and complexity, Volvo sees clear benefits to using this process, especially in the integration of different body parts and functions into one part. Tesla, for example, has claimed that it achieved a 70:1 ratio of parts per megacast. Fermér says that Volvo will achieve 100:1.

“We are looking to achieve a parts reduction ratio of 100:1 with this process. If we look at cost comparisons between a steel floor and a cast floor the price is roughly the same. But if you take a mixed material floor, the cast part is cheaper,” he says. “This reduction in the number of parts also helps with reducing complexity in the manufacturing process, for example it takes away the need for subassemblies in the bodyshop.”

The process also improves the sustainability of the parts. By building one cast-floor section close to the body line at the plant, Volvo eliminates the transport of many other smaller parts to the factory and around the facilities, many of them in shapes that don’t ship efficiently and which also risk damage. Megacasting also reduces the need for further machining operations, adds Fermér.

Compared to stamped steel parts, Volvo anticipate gaining much higher utilisation and lower emissions with megacasting since all scraps can be fed directly back into the furnace at the plant

A further consideration is that in moving from steel to cast aluminium there are reductions in CO2 emissions in the material itself. Volvo expects the megacast parts to be 15-20% lighter compared to a steel floor, for example.

Aluminium casting also helps to increase the use of secondary (scrap) aluminium, which Fermér expects to reach 50% of content. “This aluminium casting process gives us 100% material utilization,” he says. “The material comes in, you cast and everything you cut off, such as overflows, goes straight back into the furnace to be reused. This is a big difference compared to stamped parts.”

Typically, manufacturers achieve around 55% utilisation of stamped steel parts, with the remaining scrap shipped back for reprocessing into new coils, which then must be shipped again involving even more logistics and adding more CO2 to the stamping process. By contrast, casting aluminium and reusing scrap will be consolidated at the furnace onsite.

Volvo is exploring the use of alloys with 100% recycled content, however even at that level Volvo would not hit its emission reduction targets. “We need suppliers of primary material that can deliver a low CO2 product: aluminium produced with less than 4 kilo CO2 per kilo of material. This is essential,” he says.

“We are looking to achieve a parts reduction ratio of 100:1 with this process. If we look at cost comparisons between a steel floor and a cast floor the price is roughly the same. But if you take a mixed material floor, the cast part is cheaper. This reduction in parts also helps with reducing complexity in the manufacturing process, for example it takes away the need for subassemblies in the bodyshop.”-Mikael Fermér, Volvo Cars

An investment to last many lifetimes

While the benefits of megacasting are significant, Volvo also looked carefully at other processes, including ‘rheocasting’ of aluminium alloys, a process that involves using slurry in a semi-solid state. However, the carmaker has elected to start with high-pressure die-casting, as the larger casting machines make an important difference here. “One issue with casting the big parts is that you can’t have any post-casting heat treatment because this would cause the part to warp, so we need to use an alloy that offers the part performance but without the need for heat treatment,” says Fermér. “It is call F-temper alloy and we are looking into different alloys that meet the cost, ductility and strength requirements.”

Volvo is working with other foundries to develop knowledge of aluminium megacasting, as well as with other companies and universities to help build up a local competence centre

To fully develop and implement megacasting into its vehicle production, Volvo has benchmarked other companies and industries that are already using the process. “We are working with other foundries to develop our knowledge with this process. One of the biggest challenges is to gain competence in both R&D and manufacturing, so we have reached out to other companies in this sector and brought in some new personnel with the relevant experience, including people from within Volvo with experience in castings for powertrain,” says Fermér.

However, he acknowledges that the processes for these parts are quite different to Volvo’s aim to cast larger, structural parts using a different alloy. “It’s new ground for many of us. But it is a very positive step, not just for Volvo, as we work with research departments outside the company such as universities, and as we roll this process out across other [Volvo] plants we will be establishing casting competence centres to share our experience.”

With this investment in Torslanda and megacasting, Volvo is taking another big step in securing future EV development and production. While the cost is significant, Fermér points out this is not like updating a set of tooling or equipment for a platform or model cycle. Rather, megacasting is a “long lifetime” investment – and one that will further support many new lifecycles of electric vehicles.

“Typically, when you introduce a new generation of vehicles you must reinvest [in new production] all over again, but with megacasting it will simply require new dies,” he says. “So, this is new way of approaching production, not only in terms of flexibility but also speed and cost of manufacturing.”