Steel – Page 5

-

Article

ArticleMaterial changes guide the new additive manufacturing routes

Additive manufacturing is offering not only a wider range of application techniques but also materials with polymers now joined by metals and even ceramics

-

Article

ArticleSteel stays the distance

SSAB’s Thomas Müller explains how new high-strength and ultra-high-strength steels can assist OEMs in cost-effectively improving the range of electric vehicles

-

Article

ArticleE-mobility needs steel

A new report from ArcelorMittal has identified the benefits in performance and cost that steel can bring to the EV production challenge

-

Article

Articlethyssenkrupp invests in advanced forging line

Germany - thyssenkrupp will make front axles for trucks and crankshafts on the new forging line

-

Article

ArticleStrong bonds

James Bakewell looks at the challenges of joining new grades of advanced and ultra-high strength steels in the latest multi-material vehicle structures

-

Article

ArticleTaking shape

The automotive sector has seen a rapid increase in the use of high strength steel grades. But the materials provide a challenge for manufacturing engineers in the forming process

-

Article

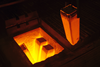

ArticleReal clean steel

With vehicle-makers and tier suppliers wanting greater performance from less material weight, Ovako’s engineering steels seem a good fit. Nick Holt visits its production facility at Hofors in Sweden to find out more

-

Article

ArticleCool processes

Across measures of quality, performance and cost Chemetall discusses how reactive oils can offer advantages in the cold-drawn, precision steel tube production process High-strength precision steel tubes are the material of choice when components must withstand high levels of stress. These steel tubes not only ensure the ...

-

Article

ArticlePressing matters

Our vehicles have all faced hazards at one time or another, from potholes in the road to rocks or broken glass. But what about protection when the hazards are ballistic threats to the safety of civil servants or service men and women? As a specialist for custom automobile protection solutions, ...

-

Podcast

PodcastAMS Podcast Episode 04 – Swedish steel and Russian reveal

AMS Editor Nick Holt describes his visit to Ovako’s steel foundry in Sweden where high strength engineering steel for long products is made, while Assistant Editor Michael Nash talks about his tour of Russia which included visits to Volkswagen and Volvo Trucks plants.

-

Article

ArticleAugmented assistance

Visit any car manufacturing plant in the world and the majority of production equipment will be similar. The real differences between factories are the human workers and the way in which technology is used to optimise their environment

-

Article

ArticleCorolla confidence

Upgrade and investments at Burnaston see Toyota start production of the new Corolla in the UK, despite all the turmoil of Brexit The UK secretary of state for business, Greg Clark, and the straight-taking Japanese ambassador to the UK, Koji Tsuruoka, joined local dignitaries, business leaders and Toyota executives in ...

-

Article

ArticleLow heat input welding

The Cold Metal Transfer (CMT) welding process reduces the heat input in comparison to other MIG/MAG processes, claims Fronius. This uses a digital process control, which automatically detects short circuits and then helps to detach the droplet by retracting the wire; during welding, the wire moves forward and is pulled ...

-

Article

ArticlePhotochemical etching for metal parts

The use of photo etching offer OEMs the ability to produce aesthetic complex mesh patterns and high definition surface engraving, claims Precision Micro. The company explains that this process doesn’t require hard steel tooling, instead, it uses digital tooling that it’s claimed offers interior trim designers greater freedom to experiment ...

-

Article

ArticlePressed, radial ISO indexable inserts

Mapal says it now offers a milling programme with pressed, radial ISO indexable inserts. The new face, shoulder, slot and shell end face milling cutters are designed for roughing and for medium machining of cast iron, steel and stainless steel, says the company. It’s claimed the tool bodies are designed ...

-

Article

ArticleDashboard meeting

Switching from gantry line to a fleet of AGVs, an IAC facility near Liverpool has brought swift and smart adaptability to its instrument panel assembly process Specialists in interior components, IAC operates in all automotive manufacturing markets around the globe. But it was its production lines at Halewood ...

-

Article

ArticlePaintshop 4.0

Nick Holt visits Eisenmann’s technology centre in Holzgerlingen, near Stuttgart, for a preview of the latest skidless paintshop technology prior to its installation at the Daimler plant at Kecskemét The skids used to convey vehicle bodies through the various coating and drying stages in the paintshop are seen as a ...

-

Article

ArticleCasting a duo

Two innovative metal forming techniques could have a significant impact on the press shop of the future

-

Article

ArticleShow and tell

Cost savings and reduced installation time are the result of Profil’s self-piercing stud, as visitors discovered at the NEAA Expo 2018A new earthing stud is allowing automotive global OEMs to achieve the triple benefits of reduced installation time and cost, guaranteed electrical earthing and a substantial reduction in parts count: ...

-

Article

ArticleA clean winner

Coherent-ROFIN’s Frank Gäbler explains a new approach to laser welding problematic materials Fig 1. Hairpin welded with CleanWeld technology: excellent weld quality, low spatter and low porosity Although fibre lasers are widely utilised in the automotive industry, there are still some applications that ...