Germany - thyssenkrupp will make front axles for trucks and crankshafts on the new forging line

Germany - thyssenkrupp has announced plans to build a new forging line to make front axles for trucks at its Homburg site in Germany. The line will cost €80m (US$90.5m), and represents the single largest investment made at the facility. Construction is due to start in early 2020, with completion due for early 2021.

”Our customers have made a conscious decision to place their orders with our Homburg site in order to secure the reliable supply of these specialised parts in Europe in times of international customs risks and rising logistics costs,” commented Alexander Becker, CEO of the forged technologies business unit at thyssenkrupp. “This will allow the Homburg site to demonstrate its production expertise, product quality and delivery performance in the international marketplace.”

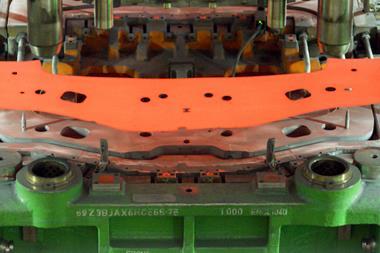

The new forging line will be highly automated. It will include a forging press measuring 10 metres in height and weighing 1,700 tonnes, with a pressing force of 16,000 tonnes. This will produce around 360,000 forged components per year, front axle systems as well as crankshafts and other forged parts.

thyssenkrupp recently said it would aim to cut emissions from production and outsourced energy by 30% as early as 2030, with emissions from the use of its own products to fall by 16%. For example, the company is currently pursuing two approaches to reducing CO2 emissions in production - converting steel mill emission gases into valuable chemicals, and replacing coal with ‘green’ hydrogen as the reducing agent for blast furnaces.

Furthermore, thyssenkrupp is also active in the e-mobility field. The company is supplying battery production lines and special steels for electric motors.

No comments yet