ArcelorMittal: smarter steels for the new world of mobility

Automotive manufacturing is evolving, fast. As the focus shifts to environmental performance, automakers need their vehicles to be lighter, stronger and more sustainable. Guided by a philosophy to produce safe, sustainable steel, ArcelorMittal is the leading supplier of quality steel products in all major markets including automotive, construction, household appliances and packaging. ArcelorMittal operates in 60 countries and employs about 23,000 people worldwide.

Smarter steels have a central role to play in this new world of mobility. Given the inherent strength of these advanced materials, cars today can be both lighter and safer. Steel can also make electric drivetrains more efficient. And it’s endlessly recyclable. We’re committed to helping the automotive industry build a better world with smarter steels.

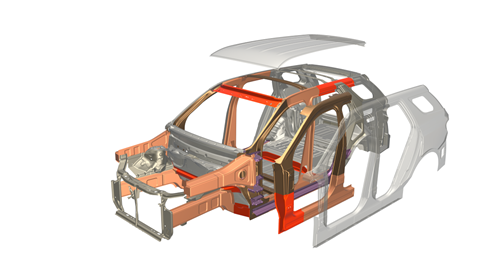

Full range of automotive steels

As the world’s leading supplier of steels to the automotive sector, ArcelorMittal is able to offer a full range of flat, long and tubular steels to meet the challenges car and truck makers face today. Whether it is for the body-in-white (BIW), closures, chassis, suspension system, electric motors, wheels, seats, fuel tank, exhaust system or windscreen wipers, ArcelorMittal has a solution available from its wide range of products. Coupled with our extensive know-how, ArcelorMittal is able to offer a steel solution for almost any vehicle application

The material that drives change

Over two-thirds of a car is typically made of steel. With focused innovation, this highly versatile material is evolving to meet the needs of the automotive industry as it transitions to carbon-neutral mobility. Today, we’ve made steels that are up to five times stronger than they were 20 years ago, so cars can be lighter, yet remain strong and safe. Our innovative electrical steels help electric motors to offer better range, efficiency and acceleration. And smarter steel solutions are protecting batteries and providing chassis for electric vehicles.

Innovation centred around the customer

ArcelorMittal invests industry-leading sums in R&D to create new steels, steel solutions and steel-making processes. Everything we do has a laser focus on our customers and their quest for materials that offer better performance and sustainability. It’s part of our commitment to supporting manufacturers’ ambitions to create carbon-neutral mobility. And to ensure our innovations match their changing needs, we embed resident engineers at our customers’ design and engineering facilities.

Today, some of our steels are five times stronger than they were 20 years ago. Cars can be stronger, lighter, safer and more affordable as a result.

Global footprint

ArcelorMittal researches and produces automotive steels and solutions on a global basis. With operations in Europe, North and South America, South Africa and Asia, ArcelorMittal is able to closely match the global footprint of our automotive customers. The establishment of our Valin ArcelorMittal Automotive Steel (VAMA) joint venture in China is a tangible example of ArcelorMittal’s commitment to maintain close proximity with our customers.

Smarter steels

Steel will continue to be the dominant material in cars, with demand expected to stay the same even as the world makes the transition to electrified vehicles. So as the design and engineering of vehicles evolves, so will the materials they are made from. Smarter steels can not only offer better strength and safety; they can also adapt to the function of each individual part, offering high levels of efficiency and sustainability. And innovations in battery technology mean manufacturers can achieve their lightweighting and driving range goals more cost-effectively with steel than with any other material.

Driven by expertise

Our steel innovation is made possible by the expertise and passion of our people. The ArcelorMittal culture is entrepreneurial and agile, rewards boldness and prizes curiosity. When we invent a new process, product or solution, our people and customers across the world benefit from it.

Explore automotive and mobility

For in-depth detail on ArcelorMittal’s products, services and solutions for the industry, including our S-in motion® steel solutions for lighter, safer and more environmentally friendly vehicles, visit our Global automotive and mobility solutions website, which features:

- Videos, features and customer case studies showcasing how our innovations are answering industry challenges

- Complete product catalogue with extensive information about our automotive steel products

- 3D car configurator to explore how our BEV and ICE steel solutions work with different car module

- Laser Welded Blanks technology, products and smart solutions in our Tailored Blanks section

- Interactive map of our global automotive footprint

- Background on our commitment to sustainability in the automotive industry

Visit our global automotive and mobility solutions website

Download our Global Automotive App to your mobile device:

ADDITIONAL INFORMATION

• ArcelorMittal automotive turnover in 2019: $11.9 billion

• Existing customers include OEMs and tier one suppliers

• Total ArcelorMittal turnover in 2019: $76.0 billion

• ArcelorMittal has a presence in more than 60 countries and has automotive facilities in Europe, North America, South America, Asia and Afr