Stellantis has announced a $3.6 billion CAD ($2.8 billion USD) investment at its Windsor and Brampton plants to accelerate its electrification plans

This supports the company’s Dare Forward 2030 strategic plan and its $45 billion CAD investment in electrification and software globally. The company says this investment will see the Windsor assembly plant upgraded to support production of a new multi-energy vehicle (MEV) architecture that will provide battery-electric (BEV) capability for multiple models and have the flexibility to adjust production volumes as needed to meet changing market demand over the next decade. Retooling is expected to begin in 2023.

The Brampton plant will be retooled and modernised, beginning in 2024. When production resumes in 2025, the plant will introduce an all-new, flexible architecture to support the company’s electrification plans. The company notes that both Ontario assembly plants are expected to return to three shift operations to support the demand for these new products and it will announce product allocation later.

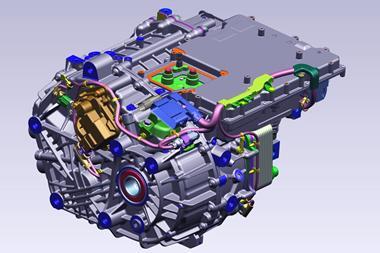

This investment will also see the company expand its Automotive Research and Development Centre (ARDC) to house the first Stellantis battery lab in North America. The ARDC will provide more than 650 engineering jobs and will focus on development of electric powertrain technologies, including batteries, power electronics, electric machines, motor controls, energy management and embedded software.

The company notes that this increases its investment in Ontario to $8.6 billion CAD when combined with the Stellantis-LG Energy Solution joint venture battery plant, which was announced in March, to establish a large-scale, domestic, electric-vehicle battery manufacturing facility in Windsor to support the company’s electric battery development.

No comments yet