The EcoPaintJet was the first series application of the overspray-free painting process in the automotive industry. Dürr discusses the next step in this technology with its enhanced EcoPaintJet Pro version

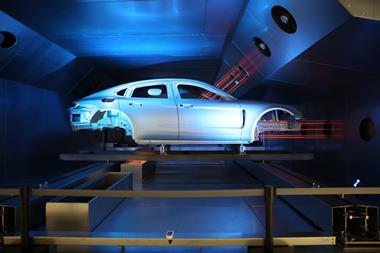

With the EcoPaintJet Pro system the robot can now paint and apply custom design elements to extremely complex body surfaces such as vertical or A- and C-pillars, fully automatically and without masking. Dürr says the precise interaction of high-tech paint application components, robotics, and software ensures maximum precision, greater energy efficiency, and minimal material use from a sustainability standpoint. The company notes that the use of this new process started in series car manufacturing this year and that the EcoPaintJet Pro is suitable for solvent and water-based 1C and 2C paints.

Dürr notes that there is an increasing demand in car manufacturing for two-tone paint jobs, such as contrasting colours on roof surfaces or A and C pillars, stripe designs, or intricate elements like lettering. Along with this trend, manufacturers’ require paintshop systems that have the flexibility to apply contrasting paint jobs with different colours and paint types on diverse surfaces, including vertical ones, without needing the body design to be changed or hindering the manufacturing process, while at the same time keeping manufacturing and environmental costs as low as possible.

“Printing instead of spraying is the future of automotive painting” – Dr. Lars Friedrich, Dürr

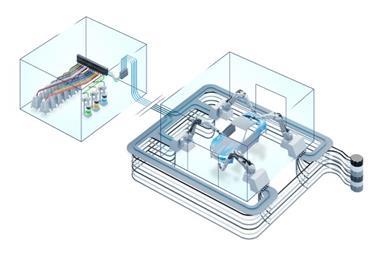

To meet these requirements Dürr has enhanced its EcoPaintJet system and developed the EcoPaintJet Pro. This robot system features an overspray-free applicator and modified paint supply process. In addition to an innovative cleaning process, it automatically checks the spray pattern, uses camera-based sensors for measuring the body as well as various software tools for robot control, generates the robot program, and adapts the painting program to the actual vehicle with accuracy down to tenths of a millimetre.

Innovative technology for more design variety

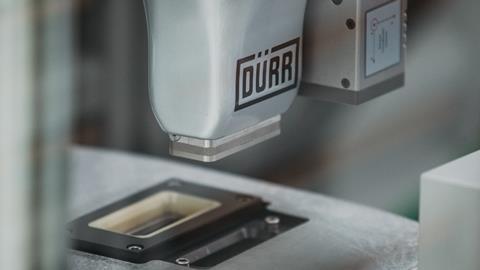

At the heart of the system is the EcoPaintJet Pro applicator, which, unlike a rotary atomiser, applies the colour with the help of an intricate nozzle plate. Several dozen, individual nozzles with a diameter of around one-tenth of a millimetre apply the colour to the body in parallel streams from up to 25 millimetres. Since 100% of the paint lands on the surface without any loss, two-tone paint jobs can be completed with more speed and less waste – even without masking, says Dürr.

The company says the nozzles opening and closing independently in fractions of a second offers completely new design possibilities for carmakers. Based on the new application principle, design elements like decorative stripes or contrasting colours are applied to the body automatically. The new system can paint large areas, apply patterns and directly transition between the two functions.

Fast colour changes without any waste

From the beginning, Dürr says it designed the EcoPaintJet Pro to make colour changes easy. Its design prevents paint accumulation, which is crucial for fast switching between two paint shades with minimal losses.

This feature is also critical when working with 2C paints because they cure quickly. The fine nozzles can become clogged by even minimal residue left after rinsing. With the EcoPaintJet Cleaner, no waste is released into the booth environment because all cleaning and rinsing processes occur in a closed system. And no overspray means no need for an overspray separation system.

Fully automated individualisation

The complex geometries of the body parts to be painted pose substantial challenges to the 3D measurement and programming of robot paths. The DXQ3D.onsite software helps operators configure the process parameters by automatically calculating the painting paths where the applicator hovers over the surface. An initial measurement registers and compensates for any inaccuracies in the conveyor technology or the body-in-white. A second sensor mounted on the robot measures the variation between the painted body and the reference model. The robot controller adapts the painting paths in real-time. The applicator’s speed and incline angle are controlled, so the colour is always evenly applied without overspray. The development of the software tools is an ongoing process, with additions and improvements regularly incorporated.

Complete process layout flexibility

With EcoPaintJet Pro, Dürr says car manufacturers can integrate overspray-free application not only into new plants, but also existing ones. Various processes that integrate at different points in the paintshop make this possible. For example, the contrast colour can be applied to the base coat following intermediate drying or as a single-layer clear coat on the cured clear coat. Masking-free two-tone painting with EcoPaintJet Pro requires much less space and energy than a comparable, conventional line, notes the company. Calculations show energy savings of up to 32% (based on the entire painting line), equating to a CO2 emissions reduction of up to 33kg per car body.

Dürr says this new process offers substantial benefits when it comes to manufacturing costs and environmental compatibility, too. No overspray means no need for overspray separation, and the fact that the rest of the body no longer needs film masking eliminates large amounts of waste. Another benefit is a better paintshop utilisation. Dr. Lars Friedrich, President & CEO Application Technology Dürr Systems AG, is confident that “printing instead of spraying is the future of automotive painting.” “Our process involves no overspray and no masking, even for vertical surfaces. In terms of cost efficiency and sustainability, Dürr has taken another step in the right direction with the EcoPaintJet.” A car manufacturer is currently integrating the new process in its manufacturing facilities and expects it to be up and running in the second half of 2022.

Permanent guest at awards ceremonies

Thanks to its innovative strength, the EcoPaintJet Pro has already won several prizes in Germany and abroad - including the German Innovation Award. It was also recently a finalist for the prestigious European Inventor Award, which is organized by the European Patent Office.

Find more about EcoPaintJet Pro here

No comments yet