All Maintenance articles – Page 26

-

Article

ArticleSolid benefits of fluid management

Growing adoption ratesReview nowTougher metals and more advanced and severe metalworking processes, along with the ongoing drive to increase productivity and reduce costs, have seen cutting fluids rise up the agenda at automotive machine shops.Where a neat or aqueous (soluble/water miscible) cutting fluid is selected, it is crucial to monitor ...

-

Article

ArticlePride in production

On a visit to Volvo’s Torslanda plant in Gothenberg, Sweden, AMS examines how the split from Ford has affected the carmaker, going on to look at the production processes put in place to handle the complicated model mixVolvo manufacturing ethosRecruitmentCost-cutting solutionsA lighter modelDelivering to the worldSwedish showcaseIn comparison to the ...

-

Article

ArticleLean and reliable identity

A report covering how Volkswagen upgraded its vehicle identification systems across BIW and paint in order to streamline production of a varied model mixSystem change: Back to the futureMoving to an integrated PROFINET communicationReduced maintenance and PROFINET communicationThe end result of a long, multi-branched production process is a vehicle of ...

-

Article

ArticleRe-condition and re-use

As markets in traditional regions of automotive manufacturing contract, new plants being built in low-cost countries are looking to benefit from installing used equipmentConveyors - a feast of flexibilityRelocation, relocation, relocationPaintshop Nano-techCamping out down at NissanCOMAUKUKA RoboterSABBRobot tradingAIDAWhile a lot of smaller manufacturing equipment is too specific in terms of ...

-

Article

ArticleSavings by design

Tata Motors at Sanand is behind the Nano and its challenge of producing and marketing the car at the given price pointColour considerationsThe Tata Nano still holds the title of the world’s most inexpensive new car. But the question remains, how do they do it? How does Tata manage to ...

-

Article

ArticleProbing for competitive gain at Audi Hungaria

Gearing up for successGet movingThe ‘art’ of measurement is portrayed nowhere so vividly than in automotive applications. With freeform body surfaces and complex, multi-featured engine components, the challenge for engineers is to get the best from metrology equipment to help develop and optimise manufacturing processes.Few can provide a more comprehensive ...

-

Article

ArticleThin white Juke

The new Nissan Juke crossover has replaced the Micra in production at the company’s Sunderland, UK plant. Nick Holt tours the facility to find out more about the overall build processes, taking a closer look at individual changes made for the new model and how manufacturing plans for the Leaf ...

-

Article

ArticleThe next frontier of smarter transportation

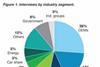

Opportunities for automakersConnectivity: The driving forceThinking outside the vehicleAMS has had exclusive access to a recent global study of automotive executives’ opinions that offers a fascinating insight into how the world of personal mobility will change over the next decade, and how the industry needs to respond.The automotive sector accounts ...

-

Article

ArticleNew hybrid solution from GKN

System designUnit production and installationWith more than 40 facilities in 30 countries, GKN Driveline commands approximately 40% of the automotive driveshaft market. The company’s latest technology involves development of the hybrid system that will feature on upcoming Peugeot models.Peugeot is set to launch production of its hybrid model range under ...

-

Article

ArticleRenault-Nissan AIMS for automation

As foreign carmakers continue to build new plants in India, the changing balance of low labour cost and automation must be revisited, as evidenced at the new Renault-Nissan plant in ChennaiAMS talked to Marc Nassif and Akira Sakurai about the ‘automation development’ of the Chennai plant and how the carmakers ...

-

Article

ArticleDoors of perception

Random temporary storage – reliable controlComplex but clearly visible control processesNetworking and consistencyAllowing for all eventualitiesThe almost universal system of dressing doors off the line and reuniting them with the right body requires sophisticated handling and software systems, as seen at BMW’s Dingolfing plantIn recent years, all processes across automotive ...

-

Article

ArticleAnodising and coating with experience

Optimising anodisingMeeting the challenge of new EC regulationAluminium cleaning, pre-treatment and anodising are some of the last finishing processes still using highly dangerous chemicals. One materials supplier is trying hard to clean up these areas For many decades, hexavalent chrome pretreatment has been the standard for aluminium. More recently, chromebased ...

-

Article

ArticleApplication expertise exhibited

Tight corners and compact carriersMoving into the third dimensionDürr’s Open House in Germany earlier this year saw all of the group’s business units presenting their innovative technologies with the motto: “Efficiency in the handling of energy and resources”In the paintshop application area, most important new model launch in is the ...

-

Article

ArticleWhen carbon counts for the better

An alternative to wet-chemical cleaningProcess technology – the decisive criterionComprehensive testing validates cleaning resultsRobot system with three nozzle arraysSmooth operation with many advantagesTopcoat line to go CO2As part of its drive towards greener paintshop processes, BMW has introduced a revolutionary cleaning technology at its Landshut plantTraditionally, plastic components for automobiles ...

-

Article

ArticleHarmonized automation

Bosch Rexroth, Hall 7, Booths 450, 550Pilz, Hall 9, Booth 370The SPS/IPC/DRIVES event, which will be held from 23-25 November 2010 at Messe Frankfurt, is Europe’s leading automation fair and the ideal event for finding out what’s new to the market, the trends, and what the future holds for automation ...

-

Article

ArticleVariations on a theme

Reducing cost in paint use and maintenanceParallel power in paint linesLess paint lost and rapid colour change possibleInside and outsideAdaptable and agileLight weight and high efficiencyLightweighting the robot armSpace-saving interfacing simplifies maintenanceEisenmann has been working hard to meet the challenges of today’s paintshop according to Ralph Meier, head of the ...

-

Article

ArticlePremium paintshop principles

Turnkey solutions and specificationsAluminium – low weight – big headache?Sludge control technologiesWet-on-wet – the way forward?Powder clearcoat – good for BMW but not JLRSourcing chemicals – the multi-supplier approachPrimerless paintColour matching challengesMatt finishes – will they ever be volume painted?Dream budgetCombining the finishing of upper-segment saloons, coupes and sports cars ...

-

Article

ArticleManufacturing in a fluctuating market

Tofas numbersDedicated tooling productionRobots in the minorityLocal sales and export issuesWorking in TurkeyAMS travels to Turkey to talk with the plant directors of Tofas and Honda Turkiye to uncover what it takes to run a successful automotive production facility in this ever-changing marketIn March this year, the Turkish government introduced ...

-

Article

ArticleNew robotic gripper from DE-STA-CO

DE-STA-CO, producer of robotic tooling and workholding solutions, has released a new electric parallel gripper said to combine improved durability with the economy of brushed motor technology. The DPE Series gripper is designed for any application currently using pneumatic grippers. DESTA- CO says that the new gripper requires no programming, ...

-

Article

ArticleSKF introduces new condition monitoring equipment

SKF has introduced a new generation of wireless condition monitoring measurement devices. The Multilog WMx provides early fault detection and prevention, while also delivering information about correcting existing or impending problems. The new equipment also analyses operating conditions in order to provide an optimised maintenance schedule, helping to improve machine ...