A battery system production factory in Hefei, Anhui province is being built by Volkswagen Group, the first battery system plant to be wholly owned by the German carmaker in China.

VW Group has announced that the annual capacity of the plant will be 150,000 to 180,000 high-voltage battery systems, intended to support Volkswagen Anhui’s all- electric vehicles based on the Group’s MEB platform.

The site will cover an area of 45,000 sq.m and be located next to Volkswagen Anhui’s production facilities. VW Anhui is Volkswagen’s first majority-owned joint venture for all-electric vehicles.

Over €140m ($164m) will be invested in the plant and its related facilities by VW China until 2025, with production set to begin in the second half of 2023.

As of SOP, the new factory employs around 200 people.

“Volkswagen Group’s platform strategy is a competitive advantage which we are transferring into the e-mobility era” said Dr. Stephan Wöllenstein, CEO Volkswagen Group China.

“With a significant increase of battery-electric vehicles (BEVs) in the future, we need to focus on keeping key components like battery systems in our own value chain, allowing us to leverage Group-wide synergies and innovations. Volkswagen Anhui and VW Anhui Components Company, alongside our two strong Joint Ventures, are crucial to our electrification strategy and to achieving our goal of the Volkswagen Group China fleet reaching over 40 percent NEVs by 2030”.

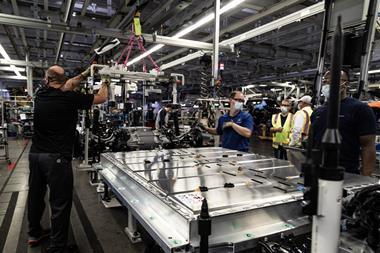

The manufacturing process at the plant will involve two production steps, each with two production lines – one for frame production and another for system assembly

Nearby, the new VW Anhui Components Company plant will be located in the supplier park of Volkswagen Anhui’s EV-production site, which allows for more logistical and cost efficiencies as well as quicker transport of products to market.

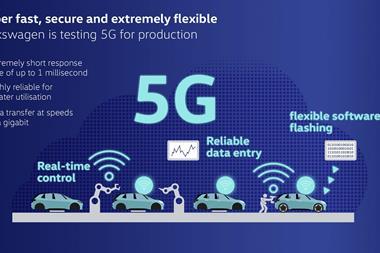

The new plant will collaborate with VW’s battery plants and workshops in Germany and Tianjin, as well as improve ties with the MEB battery plants of OEM’s Chinese Joint Ventures.

Teams at the Braunschweig plant, VW’s centre for planning, development and production of battery systems, are currently assisting with the international facilities currently being set up, such as in Anhui, and sharing their experience across the group.

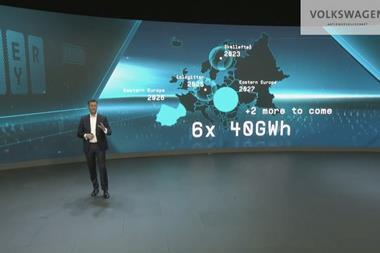

Battery assembly plants are also being established in the Czech Republic (Mlada Boleslav) and in the USA (Chattanooga), with the stated aim of manufacturing 1m battery systems per year in a few years. VW also plans to build 6 new battery production sites across Europe by 2030.

The expansion of VWs production capacity in China is part of a programme of large-scale vertical integration and the acquisition of its own cell production. In 2020, Volkswagen acquired a stake in Chinese battery maker Gotion High Tech, laying the groundwork for a range of joint ventures and in-house production.

This marks another big step by an OEM to try and secure its own battery supply chain, reflecting an industry-wide trend. A report from AMS outlines the level of investment taking planned to take place over the next decade by both OEMs and battery suppliers, to secure production capacity and supply for electric vehicles.

No comments yet