Advances in virtual testing at DaimlerChrysler are allowing it to save time and money in assessing the performance of its vehicles before they are built. AMS looks at how digital tools are enhancing quality control

We live in a digital age, so it is no surprise that the instances of digital technology having an impact on automotive manufacturing are growing by the day. Where once simulations were the exclusive domain of the design engineers, they are now being utilised by test engineers, production engineers and even marketers. And as the power of computers increases almost as fast as the prices are falling, the growth is set to continue.

Virtual testing will never entirely eliminate the timeconsuming bench and road tests on components but, according to the DaimlerChrysler Research Group, it can eliminate many problems before a prototype has been built, thereby reducing development times and costs. Complex design needs

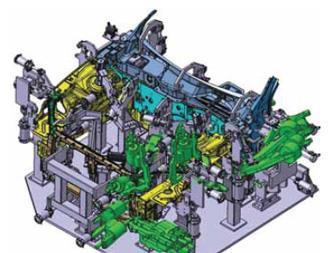

A car transmission is a complex piece of engineering. With a combination of oil heated to 70°C, steel shafts with shrouds that rotate up to 7,000 times per minute, a hydraulic system with 25 bar of pressure and an electronic control unit with at least 100,000 lines of source code for the software. Then expose this to rain, ice, snow, tropical heat, arctic cold, cobblestones and bumps for 6,000 operating hours. That is what a transmission has to endure to be fit for purpose on a modern vehicle.

This just serves to illustrate an enormous challenge of designing a powerful and robust assembly. After all, such an assembly has to operate perfectly with its mechanical, hydraulic, electrical and electronic modules, including their extensive control software, under all driving and environmental conditions.

To realise this objective, it is not enough to simply test the operation, performance, behaviour and reliability of assembly components individually and in isolation.

Whether or not the assembly will be able to pass the test as a mechatronic system can only be determined by observing how all the individual parts interact. What is more, a potential weak point will not necessarily reveal itself right away during testing carried out under defined laboratory conditions. It may become apparent only later on, during the endurance testing conducted on the road once the prototype has already been built and can be installed in a test vehicle. If design engineers encounter a weakness at this late stage in vehicle development they may well have no alternative but to carry out time-consuming and costly changes. That is why the developers look for testing methods that will allow them to ensure quality as quickly as possible – before the engine or the transmission actually exists, in other words.

At the Berlin-based DaimlerChrysler Research Group, led by Volker May, they carry out all this testing virtually using a simulation tool named MODAL. With this simulation tool, the vehicle development staff at the Mercedes Car Group and the Chrysler Group can test the operation of a new assembly more extensively than would usually be possible with even a test car. And this is true despite the fact that the component exists for the time being only in the form of data records in the computer.

At the Berlin-based DaimlerChrysler Research Group, led by Volker May, they carry out all this testing virtually using a simulation tool named MODAL. With this simulation tool, the vehicle development staff at the Mercedes Car Group and the Chrysler Group can test the operation of a new assembly more extensively than would usually be possible with even a test car. And this is true despite the fact that the component exists for the time being only in the form of data records in the computer.

The basis of the simulation method is the object-based modelling language Modelica, which was developed by simulation experts from the aerospace industry.

Its purpose is to translate physical behaviour and component features into a form that can be processed by a computer. The researchers in Berlin use this simulation language to combine all of an assembly’s components and all the external parameters that can affect it into a model in a virtual vehicle environment. The only component that actually exists is the control software.

The second important ingredient for the work of the researchers in Berlin is the simulation tool Dymola, a software tool designed by a Swedish specialist and used by the research team to establish the behaviour of the driver during the simulation. This is the actual achievement of the team in Berlin. Whereas other simulation processes — such as tests on hardware in the loop test stands (HIL) — subject software and virtual and real hardware to a fixed protocol of previously defined test cases, no two tests are alike with MODAL. At each pass, the virtual driver challenges the component.

“We encounter critical operating conditions or malfunctions that no engineer, no matter how experienced, had thought of when selecting the test cases,” explains team member Marcus Meyer. His colleague Jakob Mauss adds: “So these random moves, as it were, are just as much a part of the virtual driver’s repertoire as are the moves it uses to purposefully challenge the assembly, to expose it to situations of maximum stress, in other words.”

The computer plays through as many as 20,000 individual scenarios – gear shifting, for example, and acceleration and braking manoeuvres under all conceivable conditions. And in a complex simulation of this kind, it keeps the virtual vehicle in check throughout the entire weekend.

The computer plays through as many as 20,000 individual scenarios – gear shifting, for example, and acceleration and braking manoeuvres under all conceivable conditions. And in a complex simulation of this kind, it keeps the virtual vehicle in check throughout the entire weekend.

“Of that lot, there are in the end maybe five scenarios left over that are worth analysing more closely, because a small weakness may have been revealed in those cases,” explains Meyer.

“Over the weekend, we check far more test cases than a driver team on test tracks could, even if it worked non-stop for that period of time,” he adds. And as a further advantage, he mentions the very deep insight that can be gained: “In any given model, we can equip certain locations with virtual sensors that provide us with data about a parameter in a given operating situation.

That can’t be done with hardware components tested on HIL test stands, nor is it possible with real models.”

For team member Andreas Junghanns, the crucial advantage of the method is provided by yet another property: “We track down not only implementation flaws in the design but also conceptual errors in the design engineering. That means we are able to make statements about the quality of an assembly at a very early stage of development.

“With MODAL we don’t want to replace the testing and validation in real tests in the car and on the test stand, nor can we. The physics found in reality is too multilayered for that, with its complex factors of influence. But with the model-based analysis in conjunction with MODAL, we’re making a major contribution to what we call ‘frontloading’: identifying and eliminating weak points as early as possible in the development process in order to enter the real tests with a more mature level of development.”

Team leader May sums things up: “Increasingly often, innovative functions in modern cars require new mechatronic components, whether it’s a question of driving dynamics, assistance or comfort systems. So for an automaker like DaimlerChrysler, it’s crucial to master the development of such complex mechatronic systems. Our virtual simulation supports our colleagues in Sindelfingen and Auburn Hills in this demanding job.”

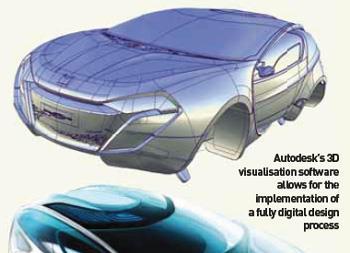

There is little doubt that Mercedes-Benz are ahead of the game when it comes to using virtual tools. Not only are they using it in design and crash testing but in smoothing production in existing and new production facilities.

“The use of simulation is still in development,” Gunter Walz, Vice President and Head of Production Planning at Mercedes-Benz, explains. “It began over ten years ago with the actual development of the car and we have to adopt that on production and with our digital factory. So when the digital car arrives, the digital factory has to be ready, and then we can make the digital car in the digital factory and discover all the problems, which traditionally we would not find until we started production.

“The use of simulation is still in development,” Gunter Walz, Vice President and Head of Production Planning at Mercedes-Benz, explains. “It began over ten years ago with the actual development of the car and we have to adopt that on production and with our digital factory. So when the digital car arrives, the digital factory has to be ready, and then we can make the digital car in the digital factory and discover all the problems, which traditionally we would not find until we started production.

“Even using simulation I believe we will never do away with the actual hardware, but the question is how much hardware do you need? And at what phase in time? So with the digital factory we try, in the phase before the hardware comes up, to solve as many issues as possible and then only do the hardware that we need.

So we still need the hardware but only at a minimum.

“First we need to decide how we can develop the digital product, then we have to bring in our requirements from production – design for manufacturing, as early as possible.

“When you look from the digital factory side it is exactly the same, we use it in the very early phase and get the early digital data for development to carry out our first test. Things such as the design for manufacture, how is it? We expect problems from the design but we can see them early. Then later on we are checking things such as the weld points. Are they reachable by the standard weld gun or do we need different ones? Our aim is to have only a few standard weld guns. When development goes ahead, the next question is what does it mean for our production system? Do we have to change it? Can we use the old equipment? Does it need modification or replacement?

This is all done in close co-operation with the product development team.

“Secondly we are always looking at the requirement of the plant, and how we can bring this all together. It is a turntable between production and development.”

When a car has been built there are the vital crash tests to be undertaken, and rather than write off a series of expensive prototypes, DaimlerChrysler has developed virtual crash simulation that is helping to cut the development times for its passenger cars. With the help of high-performance computers, the engineers can already familiarise themselves with the crash behaviour of a new vehicle even before the first prototype is built. Throughout the course of its development, they simply call up several hundred computerised crash simulation variations. These are supplemented by a number of tests carried out on the real object.

Virtual crash simulation has several advantages: for the post-crash analysis animation, the engineers can simply black out any components obstructing their view of critical areas.

Furthermore, they can also follow up the minutest details in the deformation of individual vehicle components. Other significant advantages are the shortened development times and the fact that computer simulations are more economical than real crash tests involving prototypes into which a great deal of time and expense must be invested.

The results of the simulations, such as deformation and stretching of components, or calculated speeds, match those of real tests very closely.

For the purpose of calculation, the engineers divide up the vehicle into a fine mesh of polygons – the finite-element model. This model consists of many individual small, simple elements such as triangles, quadrilaterals, cuboids or beams interconnected by nodes. The more precisely the deformation of a structure is to be calculated; the more closely-knit is this network. The body of the S-class, for example, is divided up into a mesh of some 300,000 finite elements, interconnected by about the same number of nodes. A crash, which in reality takes one-tenth of a second, is analysed by the computer in a sequence of about 250,000 stages.

For each of these time intervals, the computer then calculates the behaviour of the individual elements that deform under the load. State-of-the-art high-performance computers, often 200 times more powerful than a conventional PC, now not only analyse tests in which a vehicle collides with a barrier, but can also simulate a collision between two vehicles. The calculating capacity required for this exercise is immense.

Virtual crash simulations at DaimlerChrysler have now been firmly integrated into the vehicle development process. Nevertheless, the engineers cannot dispense with real crash tests entirely. Firstly, so-called certification tests are required by legislation, and secondly, DaimlerChrysler wishes to have documentation of real crashes at its disposal.

The simulation invariably describes the behaviour of an idealised vehicle. Not all details of a vehicle can be presented on computer, and material faults are also difficult to calculate.

The engineers therefore have no intention of replacing real crash tests entirely. Their objective is to find the ideal combination of the opportunities presented by simulations and real tests, in order to arrive at a high level of maturity within a short development time involving a minimum of prototype tests.

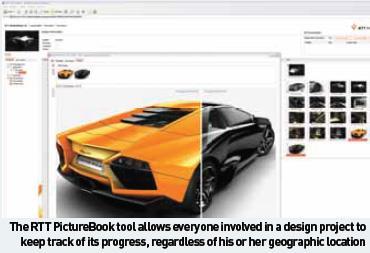

It is not just the engineers that can benefit in the digital manufacturing process, but the marketing department. Creative marketing agencies on opposite sides of the globe have developed photorealistic images for Toyota using 3D rendering hardware from ARTVPS, an industry leader in photo realistic visualisation technology.

London facility Firstbase and Australia-based Leapfrog Strategic Communications were tasked by Saatchi & Saatchi with producing digital alternatives to traditional photography to be used in separate campaigns for Toyota and Lexus.

Photo realistic rendering hardware from ARTVPS was chosen by both agencies to accurately visualise the vehicles. The specialised ray tracing technology enabled the two agencies to accurately recreate the fine level of detail required in the creation of automotive advertising imagery. Rendering cars requires a very large data set, with file sizes often over 300mb. ARTVPS technology combines the ability to render these data sets with a realism of materials that is unique.

Firstbase used RenderDrive, ARTVPS’ dedicated rendering hardware, to provide maximum performance plus speed that surpassed any other solution on the market.

John Whillock, 3D consultant at Firstbase, says: “ARTVPS’ 3D rendering technology enables us to create truly photo realistic images that even a trained eye would have difficulty spotting as fake. By creating photo realistic images within our studio, we can eliminate the need to transport expensive vehicles to remote photo shoots and have the creative freedom to place vehicles in a variety of environments to meet any advertising brief.”

Trevor Coates, owner of Leapfrog, says: “There are three incredibly important things that sell the authenticity of car images to design agencies: the naturalness of the tyre rubber, the quality of wheel finish and crucially the refractive/reflective nuances in the headlights, indicators and brake lights. Without appropriate detail in these areas it wouldn’t matter how deep the paint or how beautifully placed a car was, the image would still look like a cheap render. ARTVPS technology addresses these areas and provides truly realistic results every time.”