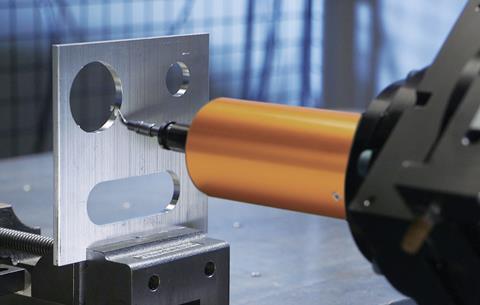

ATI Industrial Automation says its new Compliant Deburring Blade (CDB), offers pneumatic control and an articulated design that allows the contact force to be adjusted for specific applications. The company claims the tool is suited to light and medium deburring, chamfering, and scraping operations on materials such as plastic, aluminium, steel, and brass. The CDB’s axial and radial compliance is suited to maintaining constant force where surface irregularities are present.

No comments yet