Framework for adapting passive grippers in the assembly line

By Hazel Southwell2022-10-03T15:40:00

Digital framework developed to support design of passive grippers and adaptive assembly operations

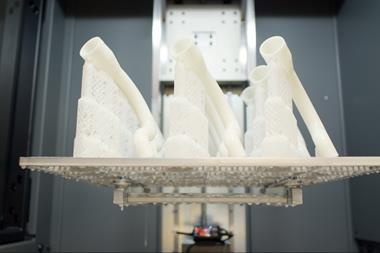

In order to make assembly lines more flexible, while still using relatively simple grippers that could be easily exchanged, the research team first had to research and write an algorithm that allowed the gripper robots to adapt to different objects and trajectories intelligently. Rather than giving them articulated grippers the scientists exchanged the grips being used, forming the new grippers with 3D printing processes and then re-taught the arms to be able to use a different technique.

The framework developed not only instructs the robot arm how to pick up an object but also designs the gripper that would work best for moving it. 3D printing was used to make the relatively lightweight grippers used in the research project, but other moulding techniques could be employed, from the same designs. This would allow assembly line robots to be easily adapted to different movements.