Reducing materials use and vehicle weight are key considerations for OEMs. ArcelorMittal discusses its new Multi Part Integration concept and how this can simplify the vehicle production process

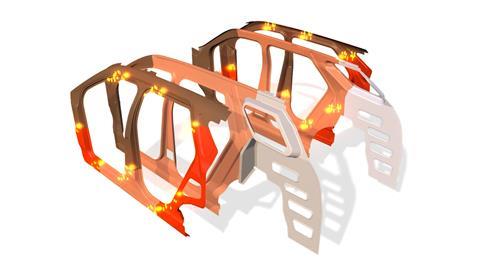

Multi Part Integration (MPI) is a new concept from ArcelorMittal Tailored Blanks which incorporates many parts into one laser welded blank (LWB). MPI uses press hardenable steels (PHS), hot stamping LWB technology, and patches (when needed) to create the new part. For OEMs, MPI simplifies vehicle production by reducing the number of processes and the factory area required. The company says this concept can be applied to all types of vehicles, including those with multiple powertrains and can deliver significant sustainability gains including a lighter finished vehicle.

The MPI concept builds on the success of projects such as the company’s S-in motion and the single-piece door ring. The door ring has been adapted for different vehicle segments and successfully introduced into several vehicles by the global automotive industry.

This new approach to produce simplified and optimised body structures uses breakthrough laser welded blanks and patch solutions. The hot stamping process gives vehicle designers greater design freedom to create parts with complex geometries. That allows one modular solution to be developed for multiple powertrains. Patches can be applied to the part to add reinforcement for a specific powertrain without increasing costs.

The use of hot stamped PHS in a single LWB is key to MPI. The LWB ensures that the right PHS steel, in the right thickness, is in the right place. The continuous weld lines enhance energy absorption and the behaviour of the part during a crash and eliminate weak points in the part.

Integrating multiple parts into one also reduces the overall mass of the part. This offers many sustainability benefits including lower CO2 emissions from reduced steel production. Further reductions in steel usage are possible with the deployment of advanced nesting techniques which enhance material utilisation.

Proven viability

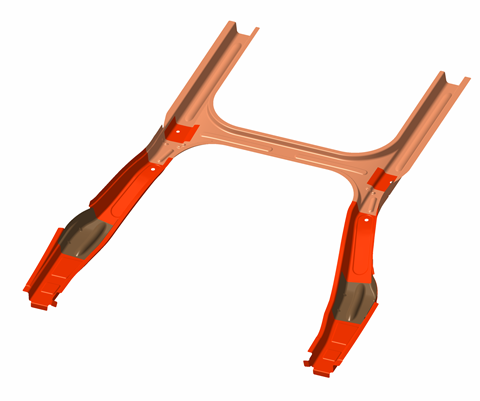

To prove the practical viability of the MPI concept, teams from ArcelorMittal’s Tailored Blanks and Global R&D units completed an MPI analysis of the rear H-frame of an S-in motion SUV vehicle. The MPI H-frame concept replaces 11 separate parts with one. The solution can be applied to almost any powertrain simply by adding patches to reinforce local areas.

The MPI H-frame concept showed that 136 spot welds could be eliminated for every vehicle, and that the footprint of an OEMs bodyshop could be reduced by half. The weight of each vehicle is also reduced by 1.4kgs which means less CO2 emissions from reduced steel production and during the vehicle’s life. The combination of LWB technology and PHS such Usibor and Ductibor has enhanced safety and ensured that the H-frame concept passed global crash test scenarios.

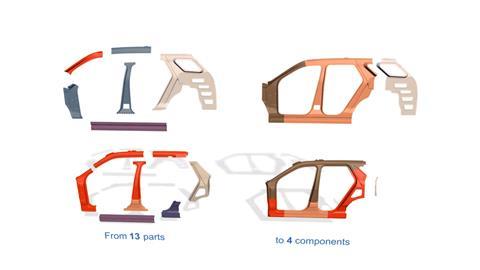

Door ring weight reduction

ArcelorMittal engineers have also applied the MPI concept to a double door ring. This combined a total of 13 parts on each side of the vehicle into just four per side. The number of spot welds was cut by 122 per side, or 244 over the entire vehicle. Overall, the mass of the body-in-white is reduced by around 20kgs using the MPI design.

The company is now working on a new MPI concept for the floor panel. The results of this study are expected to be announced later in 2021. The H-frame, double door ring, and floor panel MPI applications have passed relevant IIHS and Euro NCAP tests.

ArcelorMittal believes that the MPI concept will offer a new dimension in vehicle evolution. Over the coming years, many more MPI applications will be identified and developed in cooperation with OEMs.

Find out more here

No comments yet