Schenck RoTec has created a balancing system for e-drive production lines, which is fulfilling the needs of EV makers seeking a flexible and efficient automation solution

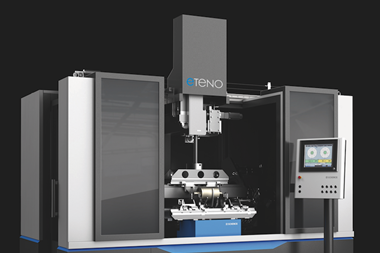

With the new eTENO, Schenck RoTec presents one of the world’s first fully automatic two-station balancing systems for flexible use in e-drive production lines. With maximum measuring accuracy and cycle times of less than a minute, it can balance and correct complete electric armatures weighing up to 50kg. Thanks to its modularity, it can also be integrated into existing or planned e-mobility processes of suppliers and OEMs in various configurations.

Increasingly, the better range and output values of electric power units and, above all, more stringent environmental regulations for internal combustion engines are increasing the demand for vehicles with alternative drive solutions. The automotive industry is rapidly addressing this by converting its early e-mobility manufacturing plants into more advanced production lines. Factory planners are now dealing with related topics, such as full automation, process integration and digitisation, and are, as a result, designing the first smart factories from where the future of hybrid and electric vehicles should emerge. In the current transformation phase, planners are striving to optimise flexibility, process performance and automation.

According to Peter Böhm, e-mobility product line manager at Schenck RoTec, this also applies to the integration of balancing technology with the development and production environments of e-mobility players. “In almost all discussions we have with OEMs and suppliers the desire for an efficient as well as flexible automation solution for balancing e-drives is at the very top of the list,” he states.

For more information about e-mobility at Schenck RoTec, visit the team at EMO Hannover 2019 (September 16-21) in Hall 6/stand F75

Customised for e-drive production

Global system manufacturer Schenck, with its world headquarters in Darmstadt, Germany, has answered this request. Working with an interdisciplinary team of design engineers and consultants, it has developed the eTENO system. Currently the only balancing system with this unique combination of functions and features, it is specifically geared for use in present and future e-drive production of suppliers and OEMs.

Böhm adds: “With the new eTENO, electric motor manufacturers, as well as automotive manufacturers, are getting an automation solution that delivers highly precise measurement results. It can also be integrated in a flexible manner into development and production settings and supports the implementation of highly efficient processes.”

The two-station machine offers fully automatic balancing and correction of complete electric armatures (rotor, shaft, cage, etc.) with weights of up to 50kg. Thanks to its modular design and a whole host of different support bearing and balancing types, the eTENO offers maximum flexibility, and features an internal handling system for workpiece changes with short cycles.

Its machine design is geared towards short cycle times and its mechanical and electrical designs meet all internationally relevant DIN/EN/ISO/UL standards. With the CAB 950 SmartTouch, it also has a premium measuring device from the Schenck RoTec product range on board. In other words, the complete system is an innovative package. “With almost 100 e-drives balancing systems worldwide for well-known OEMs and tier-one suppliers, we are the market leader in this e-mobility segment,” says Böhm.

Increasingly higher revolutions

Andreas Buschbeck, technical consulting manager at Schenck RoTec, works alongside Böhm and his department develops balancing machines designed for specific branches and products at the early stages.

“In nearly all cases, the initial idea comes from a customer who is designing a new rotor and has to know how its shape and mass will behave in terms of vibrations, and how it can be optimised in terms of balancing,” says Buschbeck. “We then determine the individual unbalance budget of the rotors. To do this, we evaluate production drawings, calculate the expected imbalance and identify the design features responsible. Manufacturers use our results to improve the quality and optimise the service life of their rotors.”

During recent years, Buschbeck and his team have tested this procedure numerous times with leading e-drive manufacturers. The knowledge gained during that time regarding the technical properties of the e-mobility drives with increasingly higher revolutions has prompted the current goal to achieve up to 30,000 rpm. The expectations of customers, in terms of flexibility and efficiency of the balancing processes, has been incorporated into the development and engineering of the new eTENO.

Schenck’s balancing system is geared towards maximum precision, best performance and flexible application. The measuring device can accommodate a wide range of complete e-drive electric armatures with shaft lengths of up to 500mm and stack diameters of up to 200mm in three different supports. Depending on the design of the armature or the request of the customer, it can come with prisms, roller bearings or aerostatic bearings. The armature is accelerated with an intelligent belt drive that releases the rotor when the unbalance speed has been reached, so that it rotates without any interference from the belt drive during the unbalance measurement. At the end of the measurement, the drive operates again and positions the rotor in the exact balancing position. When taking all optimisations into account, the measurement uncertainties of the unbalance relative to the rotor weight of only < 0,1 µm (0,1 gmm/kg) are achieved – an exceptionally high accuracy value.

Vibration-free for maximum service life

In the processing unit, the unbalance is almost entirely removed from the e-drive electric armature, so that it reliably meets two criteria: nearly vibration-free running and maximum service life. “Since these are the primary goals for balancing rotors,” adds Böhm.

The eTENO offers users optimum flexibility for this type of unbalance correction as well. With two drills, users can reduce the unbalance of the rotor on the identified position from two sides simultaneously by means of axial drilling. As an alternative, users also have the option to correct the unbalance on the rotor by means of radial drilling or milling, or by automatically inserting steel pins in the opposite angular position on the rotor.

What is new in terms of balancing technology is that the eTENO does not move the rotor during the axial correction, but rather the drills or the steel pin modules. Reversing the feed movement between the tool and the workpiece, as opposed to what was commonly used before, offers the major advantage that the individual angular position of any unbalance can be approached simultaneously on each plane for the unbalance. This happens as soon as the measurement process ends, which means while the rotor is still rotating. The result is a considerably shorter cycle time.

Communication and documentation

When it comes to control and communication technology, the highly-developed measuring system CAB 950 by Schenck RoTec makes it easy to integrate the eTENO into the customers’ production systems and IT networks. The measuring device is one of Schenck’s top products and features a software interface with clear icons and intuitive menu guidance, which machine users can use to quickly navigate through the balancing process.

With the Schenck Computer Aided Balancing Software (CAB), users can also call up all balancing technology data from their office. This helps, for example, when working on statistical process control and documentation which is necessary for quality assurance and customer service.

Like all balancing machines from Schenck RoTec, the new eTENO is also integrated into the comprehensive service and support system that the company uses to ensure the high availability of its systems. In addition to test routines, plausibility checks, and a practically oriented help system, it also offers an online remote diagnosis with teleservice.