What do you need to make your supply chain less vulnerable? Siemens explains why a holistic approach to supply chain management is imperative

When a key supplier of a critical material goes offline, what happens at most manufacturing companies? Instead of provoking distress among your manufacturing and sales teams and a mad scramble in your procurement and planning teams, what if such an event prompted a methodical and well-informed decision-making process, leading to an optimised resolution of the problem? This possibility may sound unrealistic, given today’s turbulent and unpredictable climate for manufacturers and their supply chains across the globe. However, the combination of a new, holistic supply chain management strategy and powerful, interconnected digital tools make it not only realistic but attainable.

Today’s supply chain is more extended and complex than in the past, so to develop an efficient and effective decision-making process it is necessary to have full visibility over each one of the segments composing it.

According to a research study conducted by the McKinsey Institute, companies that succeed during a supply chain crisis take it as an opportunity to embrace a transformation journey to a new supply chain model. The transformation involves all main sectors from the supplier network to distribution, and thus also involves customer service, transportation and manufacturing operations.

Manufacturing operations are a key sector. It is here where all these aspects interact and generate a complicated mix of correlations and dependencies, and where a holistic supply chain strategy takes into consideration all these internal factors. Moreover, the strategy also considers measures to address the inevitable disruptive events that are always on the horizon.

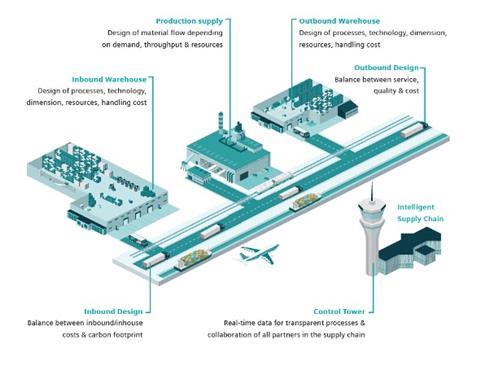

One such holistic supply chain model implements the so called ‘control tower’ approach, which is based on three pillars:

• Establish a cross-functional team to quickly make important business decisions

• Provide the team with the level of information needed to establish a data-enabled decision-making process

• Empower it with the ability to promptly conduct scenarios planning on a regular basis

This approach will equip you with the resources needed to achieve your productivity and delivery goals, even in these uncertain times. But it must be supported with the right digital tools to succeed.

Digital tools for holistic supply chain management

For the control tower approach to work reliably, both in normal times and during disruptions, up-to-date information that represents the reality of supply chain and production conditions is essential. To achieve this visibility, two primary digital systems and an interconnectivity between them are needed. The first system is advanced planning and scheduling (APS), which helps a manufacturer to optimise long- and mid-term planning and to track and make informed decisions about short-term and day-to-day production schedules for their enterprise. With this system, planners can create a production plan that accounts for production forecasts, long-term orders, and the availability and capacity of manufacturing resources. They can also create and maintain a schedule that optimises the sequence of manufacturing operations for efficient production and order fulfilment.

The second system is supply chain management (SCM), which orchestrates logistics, from planning and optimising procurement through executing pickup and transport to performing analytics. A modern SCM provides supply chain visibility and helps to optimise and manage orders, procurement, transport and routes. It makes the most of available resources, adding value at every link of the supply chain, and empowering sound decision-making processes through transparency and precision.

SCM’s domain comprises most production-related activities that occur outside the primary manufacturing floor: movement and storage of raw materials; inventory of supplied parts, components and sub-assemblies; outbound supply and distribution networks; and movement of finished goods to the customer. Thus, APS and SCM serve complementary functions, with APS focused on the manufacturing floor and SCM focused on movement to and from the manufacturing floor.

Modern APS and SCM software are designed to support a holistic supply chain management strategy like the control tower approach. Important functions of these systems support critical decision-making on production plans.

Modelling complex relationships and interactions of the manufacturing ecosystem

Both the production and logistics environments consist of resources, materials, and operations, though they differ in the types of each; manufacturing machinery is a production resource, for example, while loading equipment and transport vehicles are logistics resources. All these elements introduce constraints to production and logistics planning: warehouse space is finite, departments have a maximum work capacity, suppliers have limited processing and storage capacity, carriers have limited shipping capacity, and time is a pervasive and constant constraint on operations. APS and SCM model all the factors within their domain and how they interact with each other. Each system facilitates a step-by-step approach, starting from the basic elements (resources, operations, materials) and then building in relevant parameters up to the most complex constraints. The systems then enable you to fine-tune your model by iterations of “model and verify.”

Rapidly evaluating different scenarios

APS can run multiple production configurations, allowing you to test changes to specific details or boundary conditions. Likewise, SCM can run multiple supplier and transport scenarios. You can vary single characteristics and analyse the impact on relevant data and KPIs. These “what-if” scenarios are extremely useful to evaluate the impact of supply chain disturbances on complex, dynamic interactions. For example:

• What if a material is delayed by three days?

• What if I can get that part from only one of my suppliers?

• What if I need to expedite a customer order?

Facilitating cross functional collaboration and interaction – breaking down communication silos

Production planners and logistics planners using these modern digital tools can effectively and proactively manage inquiries coming from various internal and external sources by running what-if scenarios. They are also able to support the control-tower approach to proactively drive the supply chain.

Siemens’ support of the resilient supply chain

New holistic supply chain strategies like the control tower approach promise smoother, more efficient interactions and activities up and down the supply chain, much like a high-performance automobile provides a smooth ride over rough terrain. Expectations that spring from a holistic strategy are actualised by the synergies and advantages of production planning and logistics continuity. Therefore, Siemens is working diligently to realise deep connectivity and broad visibility between our APS and SCM solutions.

Opcenter APS software solutions have been specifically developed to enable manufacturers to react quickly and intelligently to unexpected changes, while also being able to respond to shorter lead times and satisfy customer demands. Using advanced algorithms that balance demand and capacity, Opcenter APS generates production plans and schedules that are not only achievable but also optimised for maximum productivity and cost-efficiency.

Siemens Digital Logistics offers our Control Tower solutions, which replace standalone and siloed pieces of a logistics system with a centralised, cloud-based collaboration platform. Our AX and SCS products combine to offer full cross-enterprise collaboration and transparency, including supply chain planning and optimisation, execution, and analytics.

Opcenter and Siemens Digital Logistics are part of Siemens Xcelerator portfolio, our comprehensive, integrated portfolio of software and services. Xcelerator is designed to form a software foundation for digital business transformation. It is a catalyst engineered to help you accelerate your evolution into digital enterprises, enabling you to be poised for ongoing success.

If you want to learn more how Opcenter APS and Siemens Digital Logistic join together to empower your supply chain, download our whitepaper here or view or OnDemand webinar here