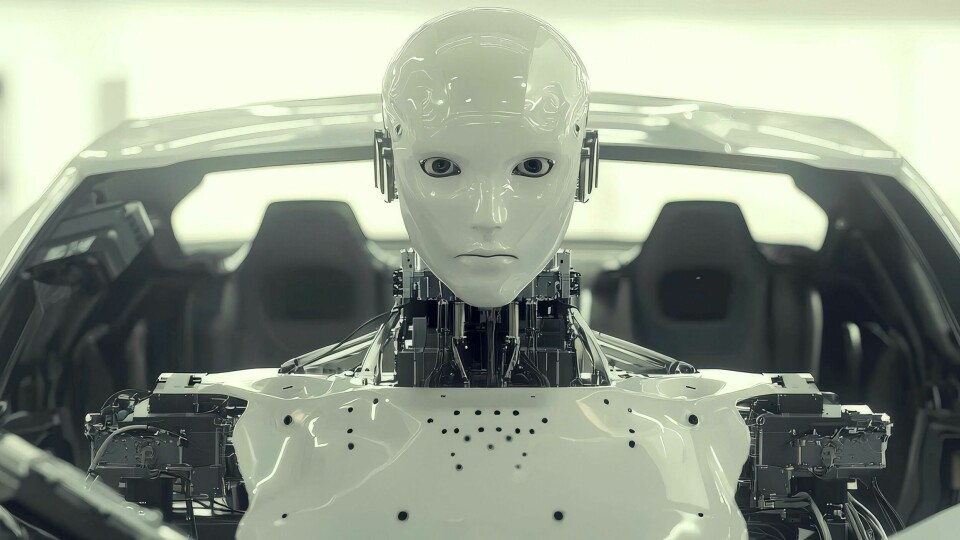

Automation gains new levels of traction as the automotive sector turns to robotics for safer, more efficient production and a redefinition of the human role on the line

A new global survey by QNX reveals how automotive manufacturers are increasingly embracing robotics to boost efficiency, address labour shortages and improve safety, while also navigating concerns over cost, trust, regulation and the future of the workforce.

The automotive industry has long been a pioneer of automation. Since the 1970s, robotic arms have populated assembly lines, spot-welding body frames and lifting panels with increasing precision. But according to a sweeping global survey published by QNX, automotive manufacturing may be entering a new, more transformational phase - one where robotics is not only embedded on the line but redefined as a strategic force touching every aspect of operations, from support roles to research and development. The impact of this shift on automotive production operations is consequential.

In “The Age of the Robot,” based on research conducted by OnePoll across seven major economies and over 1,000 decisionmakers, the automotive sector emerges as one of the most committed adopters of robotics, with 65% of businesses already using robotic systems.

And unlike sectors such as healthcare or agriculture, where uptake is uneven, automotive leaders report high levels of trust, satisfaction and ambition regarding robotics deployment.

”Respondents from automotive companies estimate that 23.3% of their current workforce could be replaced by robotics or automation over the next decade”

The outlook is expansive. Automation and production remain dominant applications - 69% and 64% respectively of automotive firms use robotics in these areas - but significantly, 39% report using them in support roles and 34% in research and development, the highest share across all surveyed sectors. That suggests robotics in automotive is no longer confined to hard mechanical labour. It is also making inroads into intellectual and collaborative tasks, including product testing and prototyping, where consistency and speed can offer competitive advantage.

Trust in robotics on the rise in automotive production but cost deters

Trust in robotics is also pronounced. Fully 82% of automotive respondents say they trust robots to carry out essential tasks, including 24% who say robots are “fully” trusted to perform these tasks “consistently and autonomously.” That compares to 77% across all industries, and, perhaps interestingly, only 63% in Japan - a country commended for its robotics deployment. Automotive workers are also more comfortable than their peers elsewhere - 70% say they are comfortable working alongside robots, and a full third are “very comfortable,” the highest proportion of any sector.

Still, enthusiasm is tempered by pragmatism. Cost remains a barrier. While the initial outlay for robotics can be steep, especially for small and mid-sized tier suppliers, automotive firms are more likely to have both the capital and scale to justify the investment. High trust is buttressed by strong safety protocols.

“Almost nine out of ten (89%) say they believe the business has implemented effective safety measures to prevent accidents involving robotic systems,” the report notes, with automotive leading here too: 45% of sector respondents believe safety measures are “very effective,” the highest of any group.

Automotive production sees automation replacing their positions in the next decade

Concerns remain over security risks and regulatory frameworks. Yet automotive decision makers are less worried than others - with only 45% citing robotics-related safety and security concerns. In fact, automotive businesses are among the most likely to view government regulation around robotics as adequate, trailing only energy and industrial automation in this regard.

Interestingly, for automotive manufacturing, the impact of increasing robotics adoption on human labour is neither dismissed nor exaggerated. Respondents from automotive companies estimate that 23.3% of their current workforce could be replaced by robotics or automation over the next decade. That figure is below the projected in China, but above the global average of 19.9%.

Read more Robotics stories

- Mercedes-Benz advances AI and robotics in production

- The robots are here: How humanoids are changing auto production

- Rockwell expands with Clearpath Robotics acquisition

- Cobots support automotive manufacturing

Yet automation is not universally feared. The biggest threats to morale are less about redundancy and more about the dilution of human agency. “Replacing jobs” and “decreasing human interaction” are cited by 37% and 35% respectively as concerns, while 35% also recognise that removing dangerous or repetitive tasks is one of robotics’ key opportunities.

Importantly, 92% of all respondents - and 99% in China - say it is important to involve employees in robotics integration planning. Automotive production appears to understand this imperative. As one of the earliest sectors to automate, it has institutional experience managing change and retraining staff. The survey highlights that leadership will hinge on how robots are deployed as well as how humans are retained and retrained as adoption rates pick up.

Ultimately, the global robotics market is projected to more than triple in size by 2030, growing from $51bn to $163.9bn. Automotive manufacturing will undoubtedly contribute to this growth, but also shape its contours. The challenge is both technological as well as cultural. To be truly successful, automakers must balance efficiency with empathy, and automation with accountability.

As the report puts it, “we are entering the Age of the Robot.” For automotive manufacturing, that age has already dawned.