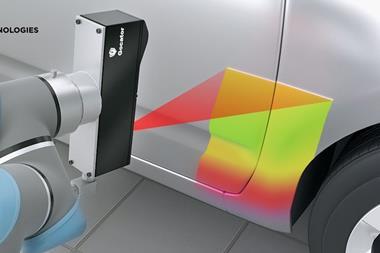

With 3D laser scanning now well established within automotive inspection applications, the challenge for OEMs and suppliers is to reduce costs and deliver high quality products. Universal metrology software for CMMs, portable arms or handheld devices furthers this desire from product engineering to production.

This webinar describes Nikon’s laser scanning capabilities and its compatibility with PolyWorks, for multi-sensor inspection and analysis. The presentation illustrates the many advantages of laser scanning versus traditional tactile probing; how scanning is closing the gap with tactile measurement; and discusses the latest software application advancements.

Tuesday 26th September | 15:30 CEST | 14:30 BST | 9:30 EDT

This webinar was presented by:

Dave Robinson, Product Manager, Nikon Metrology

Dave specialises in CMM and laser scanning products and has more than 15 years of experience in automotive metrology applications. He cooperates with key OEMs and suppliers to help them gain a better insight during production or product development resulting in improved processes and higher quality.

About Nikon

Nikon Metrology – part of the Nikon Group – offers an extensive metrology product portfolio, including CMM and laser-scanning solutions complemented with large scale metrology, state-of-the-art vision measuring instruments and microscopes. These innovative measuring and precision solutions respond to the advanced inspection requirements of manufacturers active in consumer, automotive, aerospace, electronics, medical and other industries. Nikon Metrology contributes to a high performance manufacturing process that allows companies to deliver premium quality products in a shorter time.

For more details see www.nikonmetrology.com