Preparing existing factories for manufacturing electric cars can require comprehensive upgrading of the production operations. Dürr offers some examples from its work with Volkswagen, preparing the Zwickau plant for electric car production

![]()

The large-scale shift towards electric vehicle production means enormous structural changes for final assembly. Just how far-reaching they are is demonstrated by the rebuild of Volkswagen’s shop floor at Zwickau. Since June 2020, the plant has produced exclusively electric cars with volumes set to increase to up to 330,000 units per year in the future. Dürr responded to the new challenges in final assembly with the NEXT.assembly strategy. It brings together expertise in all areas from planning and consulting to conveyor, gluing, assembly and filling technology to the end-of-line test stands and the appropriate digital solutions for final assembly. This enables manufacturers to select either individual components from a modular system or an optimised overall solution for their electric vehicle programmes. Dürr explains how this portfolio of systems and expertise has been adapted to the updating of production operations at Zwickau.

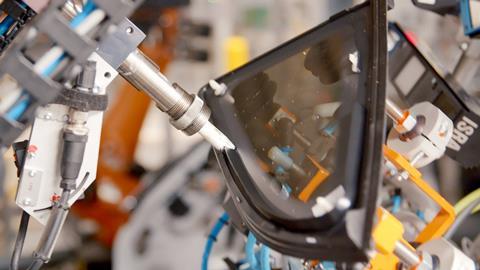

Window insertion: highly automated and flexible

The glazing centre for the Modular Electrification Toolkit (MEB) underwent significant automation during the factory modernisation. In the future, everything will be fully automated; the feeding of the large windows from sequenced transport containers and the side windows from type-specific transport containers by the logistics module, the glue application and insertion of the large windows in cycle operation and the side windows in flow operation. Previously, the automated insertion of side windows was only possible in a stop-and-go mode. The line tracking process developed in close cooperation with Volkswagen changes this, by keeping the bodies moving on skillet platforms while robots glue in the side windows. One benefit is significant cost reductions since the conveyor technology no longer needs to be adapted to the cycle operation. Moreover, the location can be flexibly selected since the side window gluing system can be integrated anywhere in the assembly line. Watch the video of this in action at the bottom of the page.

Marriage: greater speed, lower costs

The Zwickau factory is also equipped with eight x-gun multi direct screwing systems for the modified marriage process for electric vehicles. Dürr developed this system especially for bringing together the body and battery, and with it achieved an unprecedented level of automation. This patented screwing device holds up to four screws in a magazine and fastens them one after the other with just one screwdriver. With eight x-gun systems, this is equivalent to 26 screws every minute. Since intermediate spindles on pallets are no longer needed, these costs no longer apply.

Filling technology: big on variants, small on space

Different refrigerants are used for climate control in the interior of the ID.3 manufactured in Zwickau. One option sees Volkswagen using the refrigerant R744 for the first time, since its thermodynamic properties mean it can be used for cooling and heating. The energy saved in this way increases the electric cars’ range. The manufacturing changeover requires a new technological approach for the filling process too. The aim for the conversion was to fill the vehicles with R744 in the same cycle time as for the previously used refrigerants. This necessitated modernising the filling technology from the base unit to the adapters for the new adapter generation G4 Blue. By modifying the travel consoles, it was possible to integrate the new components for R744.

Conveyor technology: compatible and functional

The pilot hall of the Zwickau factory has a 256-metre-long section for overhead conveyors. In the past, 22 C-hangers with scissor lifts were used to transport the bodies. However, these are not compatible with the undercarriage geometry of the MEB platform, especially due to the high-voltage battery. Dürr therefore replaced the 22 pairs of C-hanger arms with 4-arm hangers on the subframe of the body carrier scissors lift. Since this meant it was no longer possible to convey bodies with wheels in the hanger, the scope of supply included an appropriate lifting platform for wheel assembly and the transfer operation.

In Zwickau, the individual components from the NEXT.assembly modular system have come together in a final assembly system where all processes and technologies are optimally positioned for the production of the new generation of electric vehicles.

Watch Dürr’s fully automated side window assembly process using line tracking here:

Find out more about NEXT.assembly here