Alliance in action

AMS examines the joint projects between Daimler and Renault-Nissan in terms of vehicles, powertrains, technologies, factories, geographies and timescales – and the advantages for each partner

From a near standing start in 2010, the Daimler-Renault-Nissan alliance has quickly grown to encompass projects across the globe. There has been significant technology transfer from Mercedes to Infiniti, but Mercedes has also benefited through licence fees, higher volumes for its MFA platform, and access to small, fuel-efficient engines for its growing small- and compact-car range.

Cross-badging arrangements in Japan and in Europe have enabled gaps in each side’s commercial vehicle line-up to be filled (though other gaps remain, which may yet be filled with similar arrangements in due course). There is a new vehicle plant being built in Mexico and the supply of engines between the parties is growing.

To date, there have been a few problems – such as the Citan’s poor NCAP result, and the cancellation of Renault's version of the Smart ForTwo. However, such challenges have been far outweighed by the numerous successes of the alliance. It seems only a matter of time before more joint programmes are announced.

A trio of pillars for Daimler & Renault

One of the three ‘pillar’ projects that kick-started the alliance was the shared platform architecture which underpins the new Smart ForTwo, Smart ForFour and Renault Twingo. This programme went live with the start of production of these new models in September 2014 and their launch at the Paris Motor Show.

The original plan included a Renault version of the ForTwo and electric versions for both brands, but for reasons which have not been made clear, the idea of Renault taking the two-seater model was dropped soon after the alliance was announced. In terms of electric versions, the Renault Twingo was due to be offered in electric format (Renault even said so officially, with its 2011 annual report stating that the Twingo EV would be produced from 2014), but this idea too has been quietly shelved.

However, at the Paris Motor Show last year, the head of Smart, Annette Winkler, said that electric versions of both the ForTwo and ForFour would indeed appear in 2016, although she was very cautious about what this would mean in terms of production volumes, citing the lower than expected take-up of electric vehicles in general.

Daimler, Renault and Nissan have focused on the development of a new family of three- and four-cylinder, turbocharged, direct-injection engines with a maximum size of 1.8 litres. They are scheduled to go into production at plants belonging to all three members of the alliance towards the end of 2016 and are designed to achieve market-leading positions in terms of fuel efficiency and emissions.

When the programme was announced, the companies stated that these co-developed engines would have “a high level of standardisation of non-brand relevant parts” and would be designed so that they retained “the clear distinctiveness of the individual brand identities”. The engines will be used on the high-end version of the ForFour Smart, Twingo and Clio, plus more widely in the next Renault Megane, Scenic and future Nissan C-segment vehicles, as well as the Mercedes-Benz A- and B-Class series.

Division of responsibility

The Smart ForFour is made on the same line as the Renault Twingo at the Renault Revoz plant at Novo Mesto, Slovenia, while the ForTwo continues to be made at the Hambach plant in eastern France. These vehicles are made on a ‘new’ platform that is actually a modernised version of the original rear-wheel-drive architecture that produced the original Smart ForTwo. Daimler provided the basic platform, while Renault delivered the modern EU6-compliant engines. Development costs were shared, and indeed reduced from what they would have been had each company worked on their vehicles alone, by deriving the new vehicle from the original ForTwo platform.

Although it is early days for these new vehicles, as well having benefitted from shared development costs, the Renault plant in Slovenia should also see enhanced utilisation with the addition of the ForFour to its portfolio. However, it is doubtful whether this will result in sufficient output to utilise all of its 250,000-unit capacity.

What's in a name?

The second ‘pillar’ project to be introduced was a straightforward OEM supply contract, a re-badging exercise in all but name. This involves the supply of the Citan small van by Renault to Mercedes-Benz. The Citan is a largely unchanged Renault Kangoo, made on the same line as the Kangoo at the Renault factory at Maubeuge in eastern France. This arrangement addressed a long-term gap in the Mercedes-Benz line-up, one which it had not filled since the demise of the Vaneo small van, which was an expensive and low-volume derivative of the original A-Class.

The start of this programme was problematic, as the Citan’s Euro NCAP results produced only a three-star rating, the worst for a Mercedes-Benz vehicle for more than 15 years. A number of problems were reported but have now been addressed and it is worth noting that when the Kangoo itself was tested in 2008, it actually received four stars. However, Euro NCAP standards have moved on from those used in 2008, so the ratings are not comparable.

When the programme was announced, it was reported that Mercedes’ sales target was around 30,000-35,000 vehicles a year; final production figures for 2014 have not been released by Renault as it only provides a total figure for Kangoo and Citan, but in 2013 (the only year for which Renault has released separate numbers), fewer than 17,700 Citans were made.

Engine supply

The third 'pillar' project encompasses the supply of existing Renault diesel and petrol engines for various Mercedes models, including:

• A 1.5-litre diesel unit which is made at Renault Valladolid in Spain for the Mercedes A- and B-Class

• A 1.6-litre diesel engine for the Mercedes-Benz Vito/Viano van and, since October 2014, the Mercedes C-class. This engine is produced at the Renault factory at Cléon in France.

• Two small engines for the Smart (and Twingo) programmes, notably a 1.0-litre, naturally aspirated petrol engine and a 0.9-litre, turbocharged petrol unit. The smaller engine comes from the Dacia plant at Pitesti in Romania, while the 1.0-litre unit is made at Renault’s plants in western Europe.

The benefits focus on Mercedes/Smart having quicker access to small, fuel-efficient engines for its small- and compact-car range – and also Mercedes vans – than they would have done if developing these engines alone. For Renault, higher production volumes accelerate payback on its original investment and also mean higher utilisation at its factories in France, Spain and Romania.

Nissan & Daimler's global programmes

Whereas the Renault-Daimler programmes are European in terms of location and scope, the link between Nissan and Daimler takes on a truly global dimension, with programmes covering Europe, North America and Japan. In Nissan’s case, most of its involvement focuses on its premium brand, Infiniti, and the benefits the brand gets from the use of Mercedes technology.

In Europe, the first example continues the cross-supply of engines between the brands. There is a supply from Germany of Daimler’s 2.1-litre turbocharged four-cylinder diesel engine for use in the European versions of the new Infiniti Q50 sedan which is made at the Tochigi factory in Japan.

The second example involves the use by Infiniti of core technologies from the Daimler MFA compact vehicle architecture to produce its new Q30/QX30 compact car and crossover models. Production of these vehicles will start in the second half of 2015 at the Nissan plant in Sunderland, UK. The MFA platform will also be used to support the co-development of new models, including production in Mexico (see below).

Engine supply in North America

In North America, the alliance’s first active project involves cross-brand powertrain manufacturing supply and licensing, and the establishment of a new, co-owned vehicle factory in Mexico. The first North American project involves the production of Mercedes-Benz 2.0-litre, four-cylinder petrol engines at Nissan’s new engine plant at Decherd in Tennessee; these will be supplied to Mercedes for use on C-Class models made at its factory in Alabama, and also the European version of the Infiniti Q50 sedan which is made in Japan.

This new factory involves a total investment of $319m and has created 400 new jobs; construction of the plant began in mid-2012, with the first engines coming off the line in Tennessee in June 2014. The capacity is 256,000 engines a year – far more than the current combined US production of the Mercedes C-Class and European versions of the Infiniti Q50 in Japan. It seems likely that in the future this plant will also be used to supply engines to other vehicles in the Mercedes or Infiniti, or indeed Nissan, ranges in North America and elsewhere.

From Daimler’s side, the sharing of investment costs to build its first engine supply point in North America is clearly a benefit, while the licence fees from Nissan-Infiniti will doubtless boost the company’s finances without any significant risk.

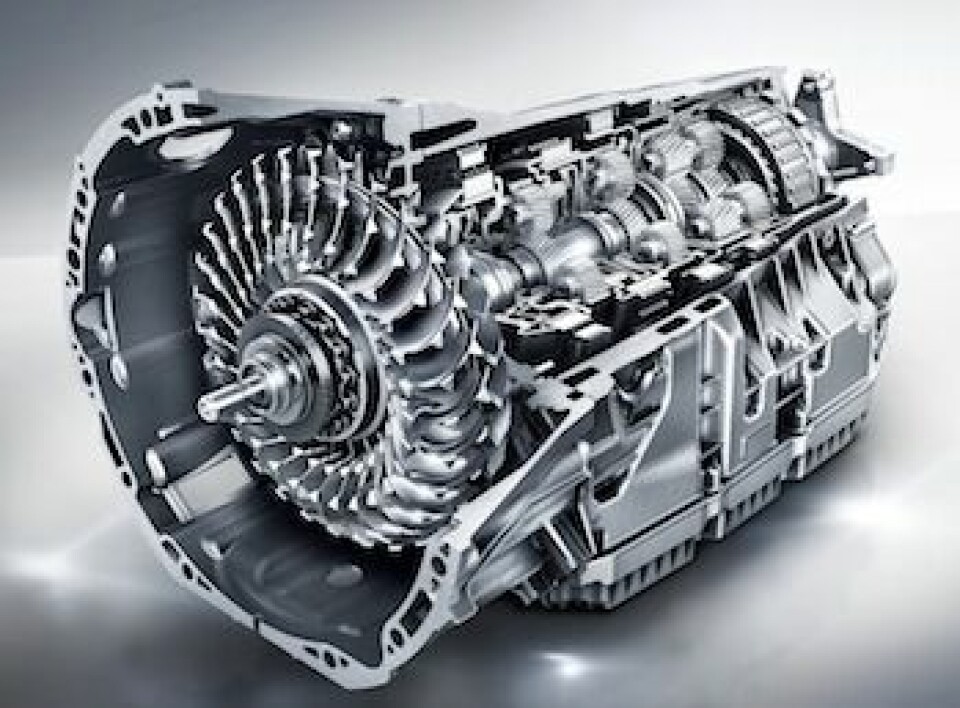

The second project in North America encompasses a licence being granted by Daimler to Nissan – which has in fact transferred this on to its transmissions supplier, Jatco – to produce the latest Daimler nine-speed, automatic transmission for use in both Nissan and Infiniti models made in North America. Jatco will produce these transmissions, which will feature ‘start-stop’ and ‘park- and shift-by-wire’ technologies, in Mexico. Here the benefit for Daimler is purely financial, through the licence fees paid, while Infiniti – and indeed Nissan – gain immediate access to leading-edge transmissions technology without bearing substantial investment costs.

Investment in Mexico

The third project in North America is arguably the most significant. This will involve the joint development of a new series of premium compact models. These will be made at a new $1.09 billion facility which will be equally owned by Daimler and Nissan; the new facility is being constructed next to the existing Nissan plant at Aguascalientes in Mexico. These vehicles will be closely related to the Mercedes A-Class and Infiniti Q30, as they are understood to be based on the MFA architecture.

In fact, Dieter Zetsche, head of Daimler, spoke of this programme being built in China, Mexico, the UK, Germany and Hungary, clearly signalling the MFA platform and the existing Mercedes A- and B-Class and derivatives (which are currently made in Germany, Hungary and China) and Infiniti Q30/QX30 (to be made in the UK). Mexican production is scheduled to begin in 2017 and the new factory will have an annual capacity of 300,000 units when fully operational in 2021. The Infiniti vehicles will be first off the production line in 2017, with the Mercedes-Benz models following in 2018.

Here the benefit to both parties is the sharing of investment costs for the Mexican factory, facilitating both sides’ entry into the compact premium segment in North America; also, the addition of more Infiniti volumes to the MFA platform improves the payback on this original investment by Daimler.

Moving on to Japan, here the alliance is currently simple, involving the cross-supply of commercial vehicles. Specifically, this encompasses the supply of the Mercedes/Fuso Canter truck for Nissan to sell as the Nissan NT450; in reverse, Nissan supplies its Atlas F24 light-duty truck to the Fuso network in Japan for sale as the oddly named Canter Guts. This cross-badging arrangement allows each side to fill a gap in its product line-up: Fuso gains a 1.5-tonne light truck and a van (for markets outside Japan, in fact), while Nissan now has an offering in the two-tonne light-truck segment in Japan.

As well as these marketing arrangements in Japan, the Nissan NV350 Urvan, which is made at the Nissan Shatai Kysuhu factory, has been supplied to Fuso for sale as the Canter Van in the Middle East since late 2014. This is a new plant, opened in 2012 with a capacity of 120,000 units per year, and also makes the Infiniti QX80, the Patrol SUV (now mainly for the Middle East) and the Elgrand minivan for the domestic Japanese market.

Finally, there is the three-way partnership between Daimler, Renault-Nissan and Ford in fuel-cell development which was announced in January 2013. This project aims to develop a fuel-cell system which will be common to all three parties, resulting in significant cost savings. The intention behind this programme is to have affordable, mass-market fuel-cell electric vehicles on the road by 2017.

However, other than indicating that this programme will be undertaken “by three companies at several locations around the world”, none of the parties has said much on the subject since January 2013.