Technical Paper: Accelerated battery analysis through connected microscopy

By Zeiss, sponsor partner

2021-08-02T10:16:00

Learn how BMW accelerated their battery analysis through connected microscopy leading to increased performance, range & longevity of batteries in electric vehicles

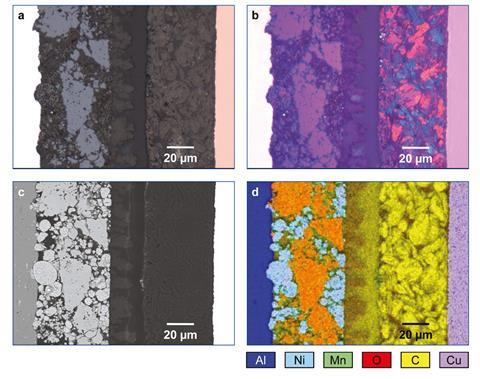

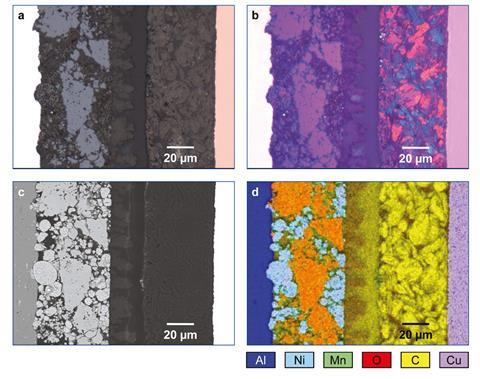

Batteries play an important role in the performance, range and longevity of an electric car. To produce efficient, reliable batteries that last, it is necessary to use top-quality materials and precise production techniques. Quality criteria range from selecting the best possible materials – including Lithium compounds, anode and cathode materials and separator foils – to control critical steps during the electrode manufacturing process. Understanding the microstructure and possible sources of contamination is key. Connecting different microscope types opens up completely new possibilities in quality assurance of batteries. In this way, the combination of light, X-ray, and scanning electron microscopes allows batteries for electric vehicles to be efficiently and accurately analyzed for faults. ZEISS Industrial Microscopy Series with coordinated hardware and inter-compatible data sets play a pioneering role here – and reduce previously time-consuming analysis workflows to just a few iteration steps.

Download the technical paper below to learn how BMW Group in Munich accelerated their battery analysis with connected microscopy!