BMW’s San Luis Potosí plant to build EVs based on Neue Klasse platform

BMW is investing €800m in its Mexican production site to integrate production of the full-electric Neue Klasse models and construction of local high-voltage battery assembly

The plant in San Luis Potosí, Mexico will produce full-electric models for the Neue Klasse in the future. BMW says that of the €800m investment at the plant, €500m is earmarked for construction of a new 85,000 sq. m assembly centre for high-voltage batteries, located on the plant grounds, which will add 500 additional employees to produce next-generation batteries.

In a recent AMS feature on San Luis Potosi, it was noted that the plant has the necessary space and weight-handling requirements on its assembly hangers to add electric vehicles without a major overhaul. Speaking with AMS last year about adding new models and increasing capacity, Harald Gottsche, plant director and CEO of the OEM’s San Luis Potosi facility said: “If you look at the layout you can see that the body shop, paint shop, assembly and logistics are separate from each other, which means we can keep the same value stream even as we increase the volume. We would be able to at least triple the production capacity that we have here and also integrate different models. For example, the hangars in the assembly, and the paint booths, are designed to integrate the X7 SUV from the size perspective and they are also designed to carry cars up to 3.2 tonnes.”

A special feature of the Neue Klasse is that the high-voltage battery is directly integrated into the vehicle structure so, assembly in San Luis Potosí is being expanded to integrate this new process into operations. A second shift will begin at the plant in April, adding another 500 new jobs.

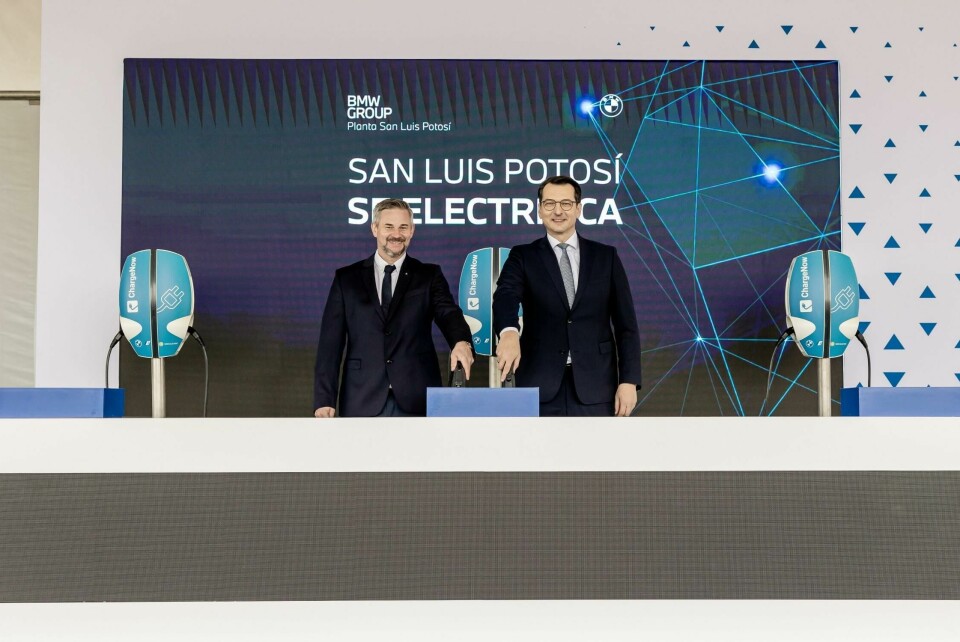

Milan Nedeljković, member of the Board of Management of BMW AG responsible for Production, said: “The first cars of the Neue Klasse will come off the production line at our plant in Debrecen, Hungary, starting in 2025, followed by the main plant in Munich. We will achieve additional volumes by integrating the Neue Klasse at Plant San Luis Potosí from 2027 onwards.”

Speaking with AMS, Plant Munich director, Peter Weber, commented on the use of digital tools being used in the planning and upgrading of the plant’s facilities in readiness for start of production of the Neue Klasse “We are developing a digital twin of the structure and processes. New buildings have digital models of those body shop, assembly and logistics structures and this platform offers the opportunity to integrate the digital twin of the production structure and new models of new structures. We are able to realise a fast, precise update based on the digital twin.”

The new EV platform will use new, round lithium-ion battery cells developed specifically for what will then be the sixth generation of BMW eDrive technology. The new lithium-ion cells which offer an energy density increase of more than 20% and a 30% increase in potential charging speed represent a “huge leap in technology”, BMW’s head of development, Frank Weber, said in a statement. At the same time, CO2 emissions from cell production will be reduced by up to 60%, as a result of cell suppliers relying on energy from renewable resources and, in the case of the raw materials lithium, cobalt and nickel, using a certain percentage of secondary material, i.e., material already in the cycle.

The company also recently announced an investment of $1.7 billion in the expansion of its Spartanburg production site in the US. This includes one billion US dollars for preparations for production of electric vehicles at the company’s US plant and $700m US dollars for construction of a new assembly centre for high-voltage batteries in nearby Woodruff. By 2030, the BMW Group aims to build at least six full-electric models in the US.