Winning the war for energy and talent: how ZF is upgrading plants and skills for growth in EVs and electronics

ZF is accelerating its use of renewable energy, building more critical components in house, decentralising its data analysis and training staff to produce more electronics. Arno Güllering talks tier-1 transformation ahead of the AMS Automotive Evolution Europe Summit in Munich.

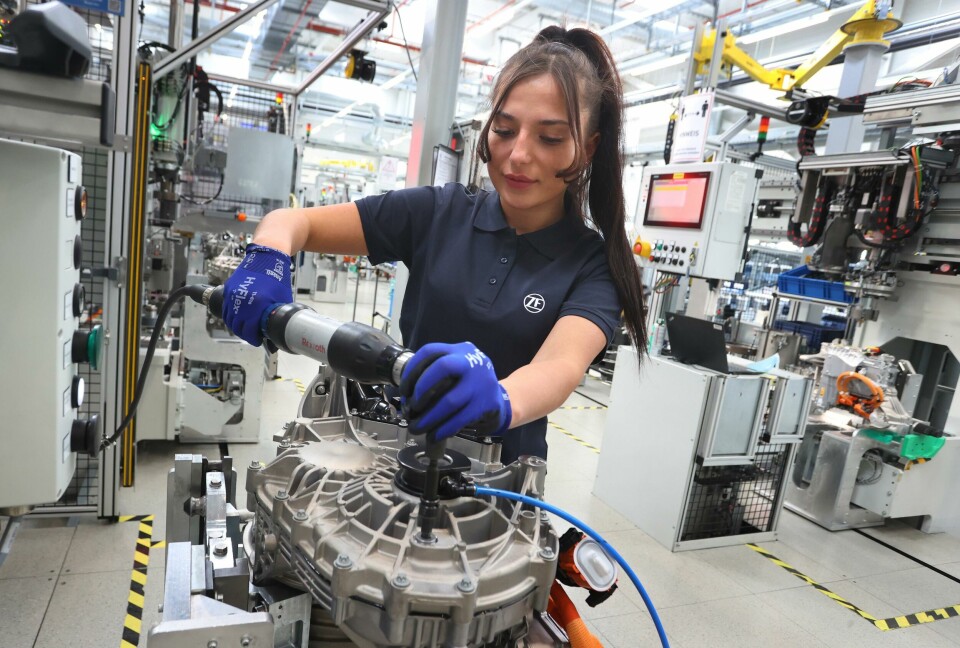

ZF has commissioned new production lines at its existing plants including in Germany, as well as building new facilities, for example in North America

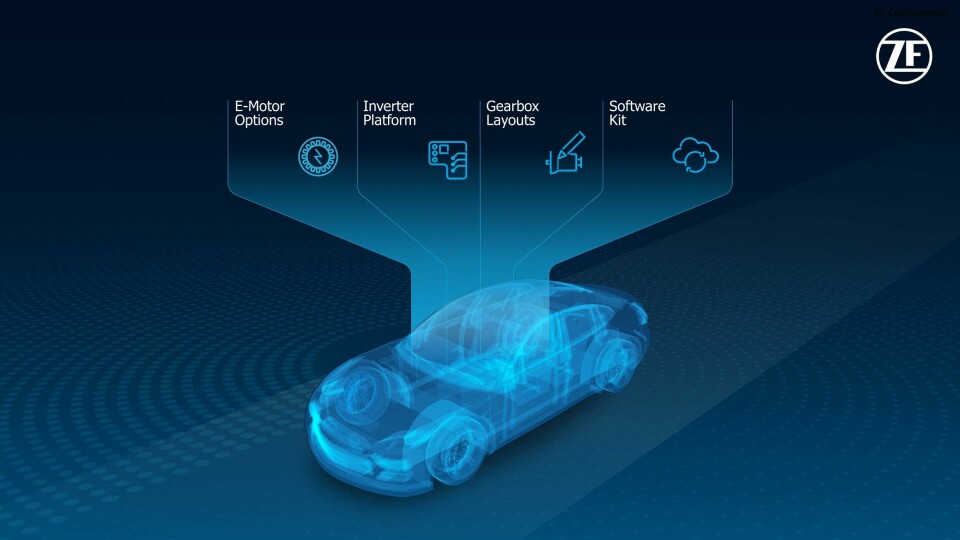

The electrified powertrain technology division at ZF is at the heart of the tier-1 supplier’s transformation to electromobility, its digitalisation of facilities and processes, and its push to reduce emissions and energy costs. The company recently produced its two millionth electric motor and has expanded production lines at its main plant in Schweinfurt, Germany, as well as in China and Serbia. It is also building a new plant in North America, which is set to start operations in 2023.

The division is also converting existing facilities globally to produce e-mobility systems, not only in electric motors but especially in electronics. ZF is now producing in-house inverters and power units, including almost all components for PCB (printed circuit board) and circuit box production.

In doing so, ZF is undergoing a dramatic shift in its product and technology focus, with huge implications for its manufacturing strategy and workforce as requirements shift from mechanical engineering and metalworking towards electronics and software, according to Arno Güllering, senior vice-president of operations for the company’s electrified powertrain division.

Güllering also points out that constraints in the supply chain of critical components, such as microchips, have led ZF to adapt the way it forecasts and plans its production, with more frequent updates and tracking of inventory. Following the energy squeeze in Europe, together with customer demand to reduce emissions, the automotive supplier is investing significantly to mitigate high energy costs and potential restrictions in natural gas supply, as well as accelerating the transition to clean energy sources across ZF’s manufacturing footprint.

Güllering, who is responsible for nearly 30 factories, is among those leading the charge towards electrification and transformation in ZF’s operations. He will join the upcoming AMS Automotive Evolution Europe Summit in Munich December 6-7 to share more on the implications for tier-1 manufacturing. In an interview ahead of the event, he points to the scale of these changes for ZF, as well as the opportunities for its manufacturing and operations team, especially as access to the company’s digital tools and ecosystem are decentralised across the organisation.

Christopher Ludwig: Automotive tier-1s are facing an ongoing ‘permacrisis’ and ‘VUCA’ conditions (volatility, uncertainty, complexity, ambiguity). What has been the most important changes that you had made to adapt to this in your manufacturing and operations?

Arno Güllering: To help us manage the inconsistency in market volume and disruption, we are keeping a very close track on our resources, to make sure we have the needed staff and material levels.

To do this, we have developed a new way of forecasting our volumes. We now update our three-month outlook every week. We’re no longer looking at the months gone by, but instead we have shifted resources from controlling and supply chain to forecasting so that we put all our capacity on looking ahead. It’s an iterative process but it has reduced the variance in our forecast and production to very minimal levels.

Has the energy crisis in Europe led you to make specific adjustments in your production?

In our division alone, we have invested €3m ($3.12m) in anticipation of a 20% mandatory energy reduction (in gas usage) year-on-year in Germany, which is what groups such as the VDA expected after Russia stopped supply. That requirement to cut energy hasn’t happened yet with the gas reserves full, but it could still come over the winter. We have nonetheless implemented measures, including reducing energy consumption in our facilities. We turn off external lights at night and use dynamic lighting in the plants. We also checked all areas where we use gas and switched where possible to other measures, such as wood chip heating.

We have also developed backup plans for components that are highly energy dependent, such as aluminium castings for gearboxes, exploring suppliers beyond Europe. This is not typically a change we would want to make as the logistics costs of moving these castings are high, but we needed to look to regions less dependent on natural gas prices, such as China.

So, is the situation forcing you to make changes which are less sustainable because of the crisis, or are you also accelerating the change to more sustainable alternatives and renewables?

There are cases where we unfortunately must take less sustainable options because of the lack of alternatives currently, however we focus much more on accelerating the switch to renewables. This shift is also quite separate from the Russia-Ukraine crisis, as our customers are putting more pressure on us to reduce carbon emissions. This applies even in best cost countries that aren’t impacted by Russian gas supply, such as Mexico, but where you might have limited supplies of green energy. In these cases, we are investing more directly in photovoltaic systems at plants at our own cost.

We have also set out clear roadmaps to reduce emissions for each plant, including installing energy monitoring systems. In Europe, many of our plants will be climate neutral by 2024-2025 thanks to purchasing clean energy. However, we are looking at where we need to intensify these plans and transitions, and for some projects we will even accept slightly longer returns on investment in clean energy. These demands are mainly coming from the market rather than the energy crisis, however if Germany were to mandate a 20% reduction year-on-year, that could change.

ZF is increasing connectivity both at new plants but also building use cases to upgrade and further connect existing plants

Is electrification leading you to digitalise production at a faster rate?

Yes and no. We are building up several new plants for e-mobility and especially for electronics manufacturing. Whenever we build a new plant, we install full connectivity. For example, we use ITech for data acquisition across production machines. However, this makes it easier to develop lighthouse projects to transfer to existing plants, and it is important that we feedback learnings from uses cases to all our plants. We see huge opportunities for operational excellence in data usage for continuous improvement, overall equipment efficient (OEE) improvement, condition monitoring and traceability.

We are moving as fast as we can towards digitalisation in existing plants because we need the efficiencies and profitability that it will bring.

Is this data collection across plants also feeding into how you forecast your production?

This connectivity helps less with forecasting, but it allows us to have a better view of our material flow. Cashflow management is key, and we need to effectively reduce stock and working capital in our production. Digital solutions allow us to see a real time analysis of inventory in the plant.

What are the most important capabilities and skills that you are introducing to your manufacturing teams?

As mentioned, manufacturing data processing is an important area, as we gather data from machines and processes to use for decision making or improving process. With even higher connectivity, we can even carry out more decision making through artificial intelligence.

One of the most important shifts for us is that we will decentralise data processing. Rather than collecting data into a central IT function, we will enable the plants to programme tools themselves. We are rolling out more digital competences, including hiring Python and Power BI experts at individual plants to help us to become more agile.

We have a strategy to provide data access for every employee, including those on the production line. We are providing all employees with email addresses and access to our digital ecosystem. We can improve data quality through having better availability, transparency and reliability.

We are moving as fast as we can towards digitalisation in existing plants because we need the efficiencies and profitability that it will bring.-Arno Güllering, ZF

How is the shift to electronics impacting your supply chain and production?

One key area is the dependence on semiconductors and microchips. We can see that access to this technology is becoming more important, with countries like the US encouraging more localisation, for example through the CHIP Act. At ZF, we have built up a new organisational unit and centre of competence for semiconductors, where we are analysing how we can reduce dependencies on suppliers and explore alternatives and multi-sourcing. We are also exploring how we can build more critical components in the supply chain ourselves.

ZF has adapted its apprenticeship programme in Germany, introduced new training and an online academy to help its staff learn new skills, including in software and mechatronics

Finally, I’d like to ask you about talent. On the one hand we see labour shortages across automotive manufacturers and suppliers. But electrification is also set to reduce labour demand. How are these changes impacting your workforce at ZF?

Speaking about numbers, we do require more workers to produce an ICE powertrain compared to an EV powertrain, at a ratio of about 2:1. That would suggest that we’ll need fewer people. However, because of our substantial growth plans in electronics, we strongly need a specialised workforce to manufacture these components. The challenge is that it is not easy to simply shift workers from one area to another, as electronic production has very special requirements. You need specialised people to operate a pick-and-place machine for PCB production, for example. It is very different to metal works. This is where we are seeing a war for talent evolving.

Our strategy is to develop as much of our own talent internally, as we see great potential in our existing workforce and its transformation towards e-mobility. To do this, we have several programmes in place. For example, in Germany we have shifted more apprenticeships from mechanical engineering to electric and mechatronic specialisations. We have also launched our online E-Cademy, an internal reskilling and upskilling initiative offering a wide range of trainings. These range from the basics of e-mobility up to so-called ‘learning journeys’, which offer employees the ability to shift their careers towards new technologies and products.