Design and manufacturing integration key to BMW’s Neue Klasse

To realise large cost and emission savings on its EV architecture, BMW is redesigning vehicles and manufacturing in parallel, and rolling out rapid digital solutions.

A class of its own: transforming BMW production for next-gen EVs

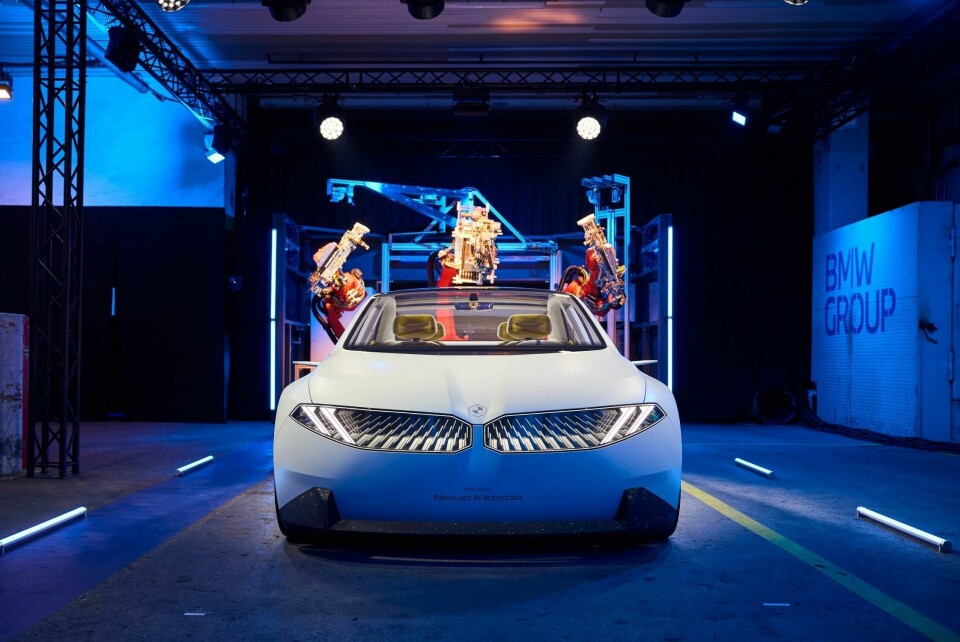

BMW Group has high expectations in making manufacturing more competitive for its next-generation Neue Klasse electric vehicle models, which it will build at its upcoming greenfield plant in Hungary in 2025, and at its revamped factory in Munich, Germany from 2026, before rolling out to other global locations.

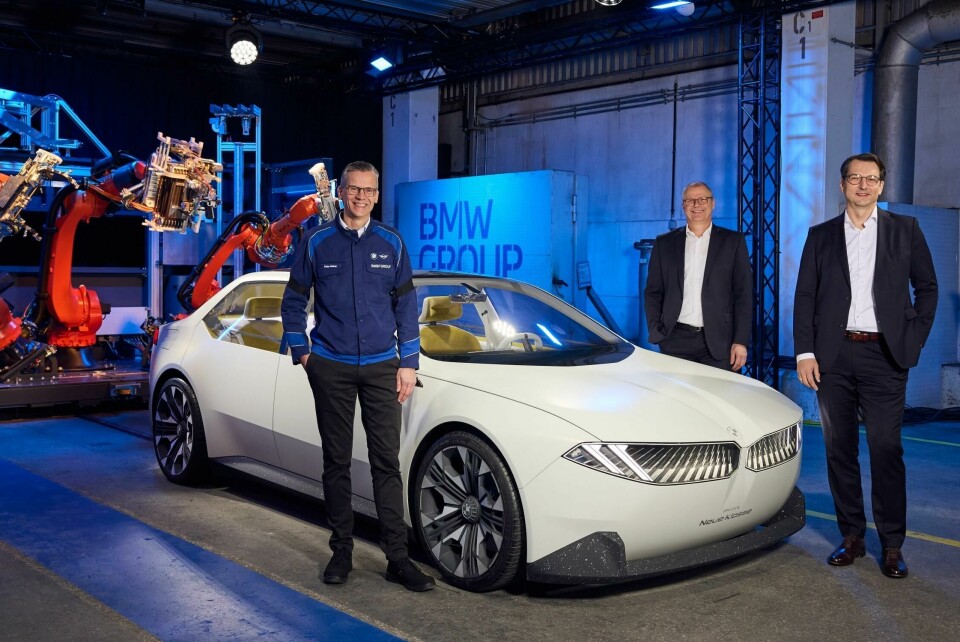

BMW’s product, R&D and production teams are working more closely together, including Peter Weber, Plant Munich director (left), Mike Reichelt, head of Neue Klasse, and Milan Neldeljkovic, board member for production

At the same time, the carmaker expects the Neue Klasse, a next-generation model series that will be based on an EV-focused architecture, to set a new tone in design language, innovation and user experience technology, along with a longer range and faster charging battery (read more about its new design at Car Design News). In another words, the new series should impress its customers as much as the original Neue Klasse, which was the basis for BMW iconic models, including the 3 Series. They should feel no cost was spared.

According to Milan Nedeljković, board member for production at BMW Group, the carmaker will reach new levels of efficiency, digitalisation and sustainability in production of the Neue Klasse. The carmaker’s goal is to cut manufacturing costs by 25% compared to 2019 levels – savings that would amount to even greater reductions compared to the increased costs that have followed the pandemic and supply chain shortages over the past four years. It also aims to increase the amount of recycled materials in the lifecycle of the vehicles to 50%.

Essential to achieving these manufacturing efficiencies and design ambitions has been “taking advantage of the production benefits” of the new EV architecture, said Nedeljković, including reducing part numbers and variations, better integrating the battery pack and simplifying body shop processes.

But to realise these efficiencies, he stressed the need for ever-closer alignment between R&D, design and manufacturing during product development and production planning phases. Such collaboration – which he has also stressed as it develops battery chemistry and production together with suppliers – is enabling the company to achieve innovations in design and engineering with production constraints and costs.

Methods for achieving these gains includes using digital twin and factory technology from early on, which allow engineers and production planners to simulate models and layouts. It is also through teams working towards shared objectives.

Plant Munich, in which BMW is spending €650m ($715m) to update facilities, layout and equipment for Neue Klasse, will be the carmaker’s first existing plant to convert to producing fully electric models by the end of 2027. According to Nedeljković, the plant, which is located close to BMW’s global R&D centre, is a chance to redesign the factory in line with the requirements of the new vehicle architecture.

He points to decisions such as using an all-steel body to support simpler forming and joining techniques, and reductions in clips, fasteners and screws, which save work, time and cost in body and assembly processes.

“Production starts in the product development phase,” said Peter Weber, director of the plant who has overseen its simultaneous transformation and ongoing operations since 2021. “For Plant Munich, our collaboration [with R&D teams] is a great opportunity to reduce complexity in production and simplify processes through intelligent product design.”

Designers and manufacturers have worked together to make material, lighting and interior decisions for BMW Neue Klasse

Working together early in the product phase has helped BMW to make innovative design, material and technology changes in ways that also supported efficiency and sustainability goals in manufacturing and supply chain, said Mike Reichelt, head of Neue Klasse at BMW.

For example, in designing the new face of the Neue Klasse, designers and engineers worked with manufacturing to use a new kind of chrome, and to reduce its overall use, supplemented by LED lighting. “In this way, chrome becomes light,” said Reichelt. The innovation not only gives the vehicle an updated, bright expression, but saves on materials.

In the interior, the car integrates driving information across the width of the windscreen, requiring further manufacturing adaptions. The teams also worked together to use more recycled material. “When we launch the Neue Klasse, around one-third of the materials used on the vehicle will be obtained from secondary raw materials, and this level will increase over the lifecycle of the car,” says Reichelt.

“Production starts in the product development phase. For Plant Munich, our collaboration [with R&D teams] is a great opportunity to reduce complexity in production and simplify processes through intelligent product design.”

The goal of using recycled materials and reducing lifecycle emissions also informed other design, engineering and material decisions, adds Nedeljković. Along with simplifying joining processes, the steel body enables BMW to use a higher proportion of recycled material and to implement loops. It was one of the reasons that the OEM ultimately decided against a ‘gigacasting’ approach that forms large, single aluminium body panels and parts, he said. Gigacasting, pioneered by Tesla and since favoured by other OEMs including Volvo Cars, GM and Mercedes-Benz, did not support the same level of circularity as a steel body for BMW, according to Nedeljković.

A digital production system, future proofed

Peter Weber stressed that the changes at the factory will further reduce cost and improve the competitiveness of production at Plant Munich, which is being redesigned to optimise manufacturing speed and flexibility. Investment includes the construction of a new body shop, along with new and expanded assembly and logistics operations, which will cut distances between each production phase (with body-in-white, painted bodies from the existing paint shop, and assembly linked in a compact U shape), supporting faster material flow, higher automation and reduced logistics handling. The buildings are also being built to support and automate the movement of batteries, which can weigh up to 600kg, including new conveyor and rail lines.

Weber also highlights advanced digital production systems in areas including data analytics, virtualisation and artificial intelligence to support employees in their work, especially in quality management, training, logistics, factory design and production planning. For example, a dashboard tool is available to all managers and team leads that shares real-time information on production performance KPIs, including material steering, incoming goods, assembly status and critical inventory. Augmented reality and video tools are used to support worker training.

BMW’s digital factory tools, which include mobile mapping and image specialist Navvis, and Nvidia’s Omniverse virtual reality, are helping BMW to improve processes at Plant Munich. The carmaker’s ‘Factoryverse’ combines master data from plant and vehicle designers to create a virtual version of future facilities under construction, allowing engineers and assembly planners to simulate changes and their impact on the shopfloor.

AI is also being used more widely in error detection scanning, maintenance and in supporting automation of more dynamic operations, including logistics picking and smart transport robots. According to Weber, Plant Munich has also begun to use large language models and generative AI to support production planning and process design.

The carmaker favours a “bottom-up approach” to digital production, said Weber. As part of its iFactory strategy, in collaboration with the OEM’s IT department, BMW encourages a ‘no code, low code’ approach, which allows employees to create new applications without coding knowledge. A recent hackathon, for example, saw 40 employees create 20 new apps; among them, a system to scan and capture packages for transport damage via mobile phones when goods arrive at the plant.

“We have a great variety of tools and we have terabytes of data. The most decisive success factor is to integrate the data, technology, process and people,” said Weber.

Self-steering, connected production – powered by smart batteries

Nedeljković suggested that Munich, along with other BMW plants as they produce next-generation vehicles, will accelerate digitalisation significantly once they start using the intelligent systems and software embedded within the vehicle, which BMW will use to steer production processes.

For example, by harnessing the visibility and control systems in the battery pack, which will be integrated early to the chassis, he anticipates that the vehicle will communicate directly with robots, manufacturing equipment and systems, helping to ensure installation of correct parts and modules, as well as to verify quality and diagnostics.

“We will come up with a completely different way of manufacturing and steering the whole plant by using the cars as an intelligent asset in the whole system,” he said. “Much of the testing equipment that we use today in the factory for testing software diagnostics, for example, will become redundant.”