UK industry faces EV & cost slump

UK automotive output slumps amid EV and cost challenges

UK automotive manufacturing faces its toughest half-year since 1953 outside the pandemic. While EV output grows, cost pressures, unclear incentives and supply shortages threaten recovery plans.

The UK automotive industry is under severe pressure, with production down 11.9% year-on-year and the worst first-half performance, excluding Covid, since 1953. The industry is facing challenges including the shrinking of export volumes, high energy costs, low domestic supply of EV components, and an imbalance in supply and demand for EVs. On top of this, there is confusion spanning from customers to OEMs about which vehicles qualify for EV mandates. However, recent government funding could provide hope for recovery.

Declining vehicle production in an export-heavy UK market

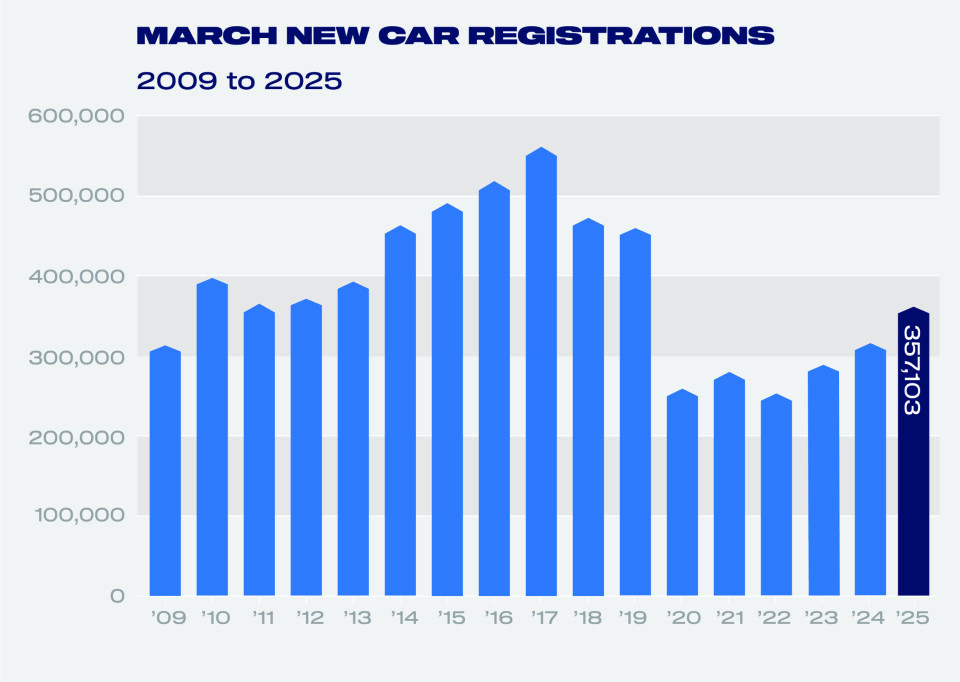

In the first half of this year, new vehicle manufacturing declined by 11.9% to 417,232 units, according to the latest figures from the Society of Motor Manufacturers and Traders (SMMT).

The UK’s output of cars this year to date declined by 7.3% to 385,810, while production of commercial vehicles almost halved, declining by 45.4% to 31,422 units, due in part to restructuring at commercial vehicle production plants.

It has been one of the toughest periods in the history of the UK automotive industry.

The overall year-on-year decline was softened slightly by a 6.6% increase in car production in June compared to the same month last year. In June 2024, model changeovers and supply chain issues held back output, accounting for the YoY increase.

While the forecast for the full year has been revised from 818,000 units to 755,000, the SMMT does expect a recovery, albeit a slow one, over the next few years. In a press briefing, Hawes said: “We do not expect to get back to a million [units produced annually] before the end of the decade under current conditions and current participants.”

For this to happen, there would need to be new entrants in the market, he said. However, the SMMT does expect to see production rise to more than 800,000 units next year, and 850,000 by 2030.

EV production rises but supply chain gaps persist

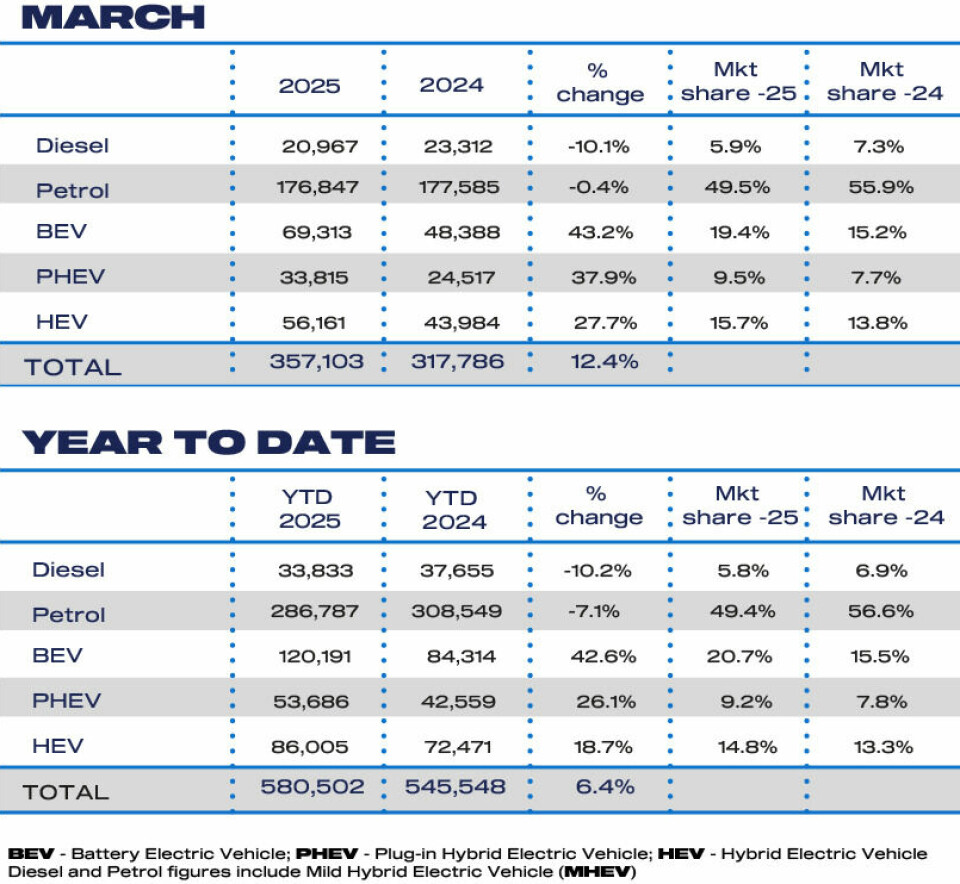

EV production not only saw a rise of 1.8% in the first six months of the year, but it also took on a record share of overall production, with EVs and hybrids accounting for more than two in five cars produced in the UK, at 160,107 units.

However, there is a mismatch between EV production intent and supply capability. The domestic EV supply chain is running short on components including e-axles, wiring and battery casings. Local production of EV batteries is still scaling, with assurances made for AESC’s second gigafactory in Sunderland, but is not yet widely operational.

Government funding and industrial strategy

The UK government has injected cash to boost incentives for domestic EV production through the £2.5bn Drive35 industrial strategy, which includes support for EV supply chains, skills and decarbonisation. Manufacturers including Nissan, JLR and Toyota have announced major investments this year, alongside recent projects in UK plant upgrades.

With rapid delivery and the right conditions, UK automotive can reverse the current decline

However, reducing energy costs remains the number one priority, according to the SMMT. UK-based OEMs and parts manufacturers are paying up to double what their EU peers do for energy. Because of this, Chinese and European manufacturers are investing instead in Hungary, Turkey and Spain, where energy costs less and renewable supply is abundant. Explore the impact of energy costs on UK competitiveness. “That is something that remains a focus to improve our competitiveness,” Hawes said.

EV grant sparks industry confusion

While the UK government has also announced a £650m consumer subsidy to stimulate EV demand, it has caused confusion among OEMs as to which models can qualify. The grant offers up to £3,750 off new EVs priced under £37,000, but its application is complex and was launched without consultation.

Hawes said: “Right now, your local car dealer can’t tell you for sure whether the car you’re thinking of buying will qualify.” The uncertainty adds another visibility gap in forecasting ability, putting production planning at risk.

A slow (and winding) path to recovery

The SMMT remains cautiously optimistic that investment, industrial strategy delivery and energy reform could help reverse the current decline. The UK retains strengths in engineering, R&D and premium manufacturing, but achieving long-term growth depends on securing at least one new entrant to the market and accelerating domestic EV supply chains.

“The industry is moving to the technologies that will be the future of mobility… With rapid delivery and the right conditions, UK automotive can reverse the current decline and deliver the jobs, economic growth and decarbonisation that Britain needs,” Hawes said.

We do not expect to get back to a million [units produced annually] before the end of the decade under current conditions and current participants

UK production analysis & Insights

The deeper story behind the numbers is one of structural competitiveness. Hawes was candid that tariffs and trade disputes have exacerbated what is already a fragile situation. The US decision earlier this year to impose a 27.5% tariff on UK-built vehicles forced manufacturers to adjust production and hold back exports. The subsequent deal to cut tariffs to 10% was described as “a significant diplomatic achievement,” but the quota of 100,000 units caps growth potential for luxury brands that depend heavily on US sales. Any future tightening of these rules could destabilise forecasts again.

Energy remains the Achilles’ heel for UK production. While government measures will shave around 20% off bills, costs will still be among the highest in Europe. Spain and Turkey have become attractive for new EV investments, offering lower costs and abundant renewable energy.

Intervention, electrification and a two-tier market

Without further intervention, the UK risks losing the race to secure new entrants - something Hawes called essential to meeting the government’s ambitious 1.3 million-unit annual production target by 2030.

On electrification, the rise in EV output masks underlying weaknesses. Critical production components such as battery enclosures, e-axles and wiring harnesses are still heavily imported. Domestic battery capacity is improving, but Hawes cautioned that timelines remain tight: AESC’s second Sunderland plant is expected online later this year, while Tata-owned Agratas is unlikely to start production before 2027. Until then, UK-built EVs will depend on imported cells, complicating rules-of-origin compliance and cost structures.

The need for energy cost reform, accelerated EV infrastructure, and consistent industrial policy

The EV grant was intended as a catalyst but risks creating a “two-tier market,” according to Hawes. Brands that fail to meet the science-based target requirements or miss eligibility criteria could see their competitiveness erode overnight. The timing has also been disruptive, coming ahead of the crucial September registration month, when manufacturers had already committed production schedules and marketing spend.

Looking ahead, recovery hinges on three factors: energy cost reform, accelerated infrastructure for EV supply chains, and consistent industrial policy. The UK’s strength in high-value engineering and R&D offers a foundation, but without competitive cost structures and policy clarity, production volumes are unlikely to rebound quickly.

Despite this UK production slump, however, the nail is not yet in the coffin, as auto producers fight to find ways to resurrect a once-burgeoning manufacturing hub. The project continues. As Hawes says, "I think one thing we have learned, anything can change."