Battery technology

CEA and ProLogium partner to develop removable and recyclable solid-state battery module

The prototype will aim to showcase how Design-for-Disassembly could reshape battery production and recycling in Europe, which will be demonstrated at IAA Mobility 2025.

French research organisation CEA and solid-state battery innovator ProLogium Technology have announced a strategic partnership to develop battery modules featuring "Design-for-Disassembly" architecture, marking a significant step toward sustainable automotive energy solutions.

A prototype of the innovative battery module will be demonstrated at IAA Mobility 2025 in Munich from September 9-11, providing automotive manufacturers and industry stakeholders with their first look at the technology's practical applications.

Addressing industry sustainability challenges

The collaboration, which began in November 2024, tackles one of the automotive industry's most pressing challenges - battery recyclability. Conventional liquid batteries have increasingly adopted closed architectures like Cell-to-Pack (CTP) and Cell-to-Chassis (CTC) designs to maximise energy density.

However, these approaches create significant sustainability issues. When a single cell fails, entire modules often require complete scrapping, generating substantial electronic waste.

"The enhanced module architecture enables individual cells to be replaced independently, thus significantly reducing electronic waste, shortening repair times, and optimising overall costs," the companies stated in their joint announcement.

Technical innovation meets sustainability

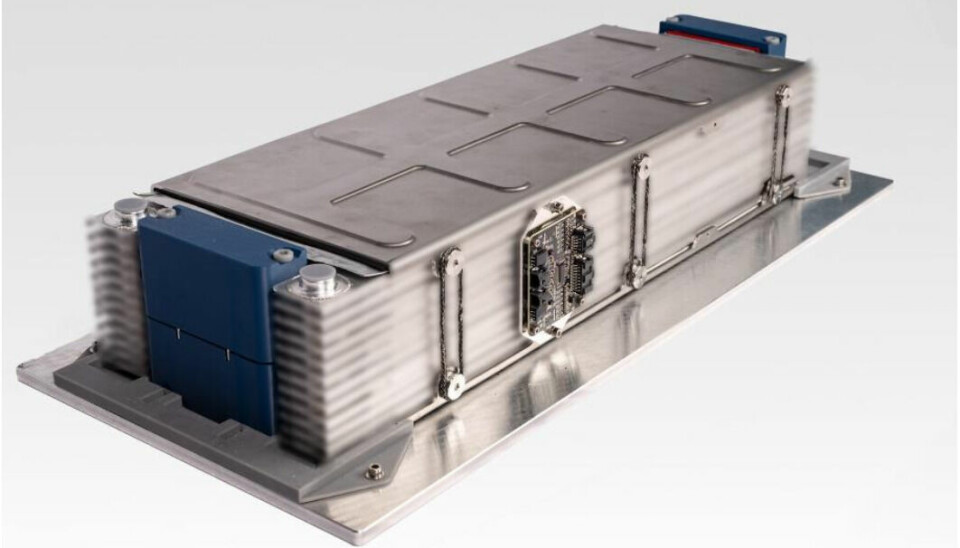

The partnership combines CEA's extensive expertise in module design, prototyping, and testing with ProLogium's proprietary "Superfluidised all-inorganic solid-state lithium ceramic battery cells."

The technology's ultra-fast charging capabilities could significantly reduce downtime for electric vehicles, while superior low-temperature performance addresses a key limitation of conventional lithium-ion batteries in cold climates.

The breakthrough lies in creating a non-welded, modular design that maintains both compactness and high energy density traditionally competing objectives in battery engineering. This enables the module to be easily removed from battery packs and disassembled to access individual cells, facilitating component separation for recycling and enabling targeted repairs rather than wholesale replacement.

The collaboration's approach also enables three critical sustainability metrics - enhanced reparability, improved recyclability, and increased reusability.

Unlike conventional modules where cell failure necessitates complete replacement, the new architecture allows technicians to identify and replace individual failing cells, dramatically extending module lifespan and reducing material waste.

Strategic implications for European battery independence

The collaboration supports broader European objectives for battery industry autonomy and the energy transition. As automakers face increasing pressure to demonstrate circular economy practices and reduce environmental impact, the partnership offers a concrete solution for sustainable battery lifecycle management.

The timing aligns with Europe's push for battery supply chain independence, particularly as the automotive industry transitions toward electrification. ProLogium's European expansion, including its planned Gigafactory in Dunkirk, France, positions the company as a key player in this strategic initiative.

Circular economy implementation

The Design-for-Disassembly concept extends beyond simple cell replacement. The architecture facilitates comprehensive material recovery, enabling separation of different cell components for specialised recycling processes.

This method supports the automotive industry's transition toward circular economy principles, where materials maintain value through multiple lifecycle stages rather than becoming waste.

The modular design philosophy also enables potential second-life applications, where batteries that no longer meet automotive performance requirements could be repurposed for stationary energy storage applications, further extending material utilisation and economic value.