Hybrids & Hydrogen in EV Age

Why range extenders, hybrids, and hydrogen ICEs still matter in the EV era

Mahle Powertrain’s Mike Bassett tells AMS how advanced simulation, clean-sheet design, and targeted hybrid integration are driving the development of next generation internal combustion engines for EV platforms.

Despite the automotive industry’s push toward electrification, demand for internal combustion engine (ICE) development remains strong – though increasingly specialised. According to Mike Bassett, Director of Engineering at Mahle Powertrain, the market has become “very polarized,” with interest focused on two extremes: high-performance hypercar engines and highly efficient range extenders.

The range extender needs to be compact, efficient, and optimised for a specific duty cycle. In many cases, it’s placed where an axle would go in a four-wheel-drive EV variant

“We’re seeing demand for very high-performance V12 extreme engines – sort of a ‘last hurrah,’” says Bassett. “At the other end, the focus is on range-extended applications, particularly for electrified platforms where space constraints require innovative packaging.” Mahle is currently engaged in multiple active OEM programs for both segments.

Range extenders gain traction

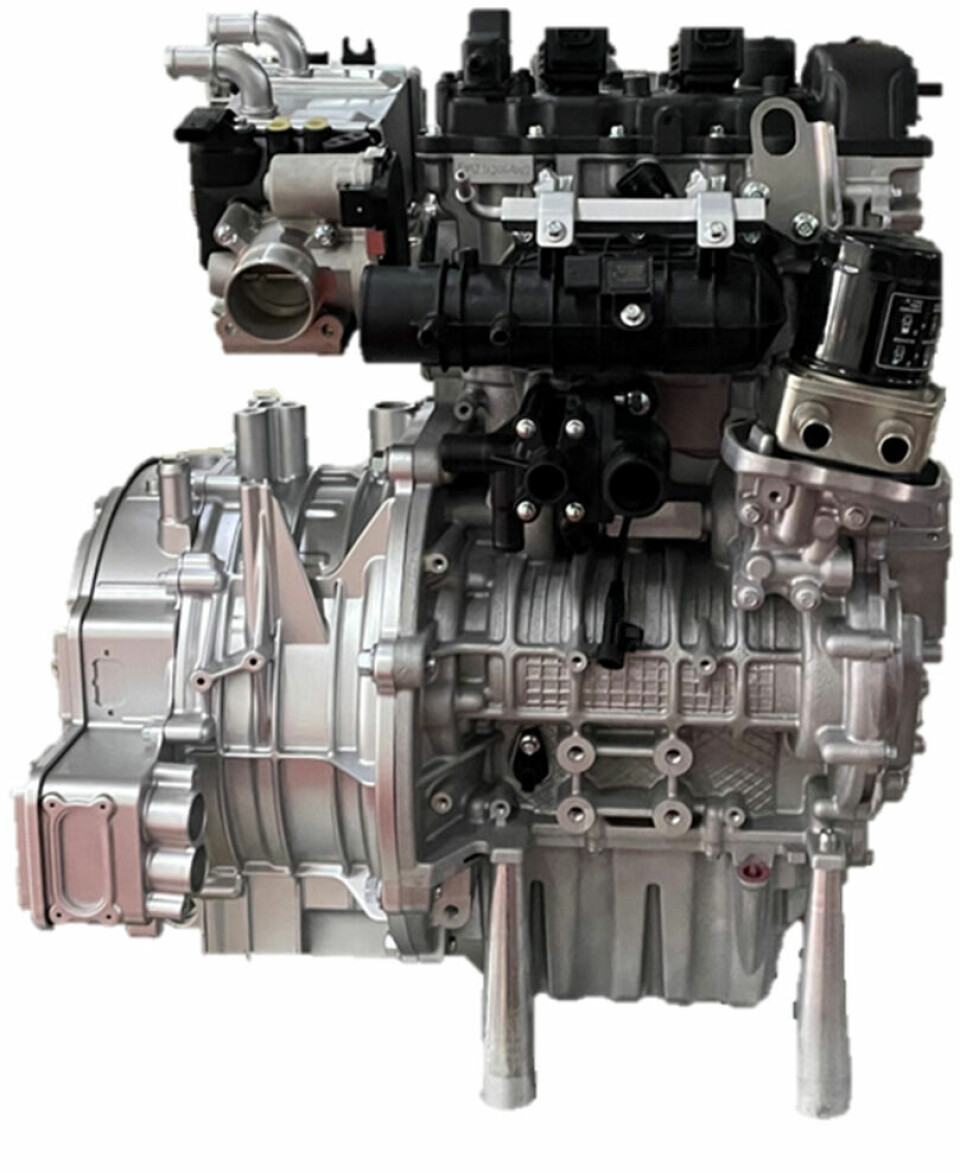

Interestingly, range extenders – once considered a niche or transitional technology – are now experiencing renewed interest. “We designed a clean-sheet range extender engine 15 years ago and demonstrated it in 2012,” Bassett notes. “Interest tapered off until recently. Now, we’ve got two large programs underway.” These clean-sheet designs are typically driven by the packaging needs of EV platforms, where space for traditional engines is limited or non-existent.

This resurgence in ICE development is often quiet, Bassett acknowledges, due to “bad marketing” optics. But from a technical standpoint, these systems are crucial. “The range extender needs to be compact, efficient, and optimised for a specific duty cycle. In many cases, it’s placed where an axle would go in a four-wheel-drive EV variant,” he says.

Efficiency and emissions are key metrics, especially in China, where regulatory pressure is high. “The fuel consumption targets are aggressive,” Bassett emphasises, noting that ICE systems for range extenders are often simpler than conventional engines due to steady-state operation and limited transients. “You’re not calibrating for harsh acceleration. That simplifies controls, emissions management, and noise, vibration and harshness (NVH) optimisation.”

OEMs are designing all-electric platforms and then realising they can serve more customers by integrating a range extender – but space is tight

Range extender technology and design

Range extenders differ from the mainstream ICE powertrains in being used to power a generator to charge an EV’s battery when it depletes, extending its driving range. These are most often used in series hybrid architectures where propulsion is handled by electric motors alone. “It’s not a hybrid in the traditional sense,” Bassett notes. “The engine doesn’t drive the wheels – it charges the battery.”

Interestingly, clean-sheet design is increasingly favoured over repurposing existing engines. “That’s driven by packaging challenges,” Bassett explains. “OEMs are designing all-electric platforms and then realising they can serve more customers by integrating a range extender – but space is tight. One of our engines is being designed to fit where a drive axle would normally sit.”

These packaging constraints push requirements for extremely compact, efficient engines. The architecture must also account for fuel tanks, exhaust routing, and thermal management – without significantly impacting overall vehicle design. Despite this complexity, the engines themselves are often simpler to operate and control. “Because they run in steady-state conditions, the calibration is more straightforward than conventional engines,” says Bassett. “You don’t have to handle rapid acceleration or driver-induced transients.”

Digital tools and simulation play a crucial role in speeding up development. “Chinese OEMs in particular want a one-phase programme – prototype to production with minimal iteration,” he says. “We often go from concept to working prototype in nine months. There’s no room for error – it has to be right first time.”

Noise, vibration, and harshness (NVH) considerations are also central to range extender design. “Contrary to the idea of running at a constant speed for efficiency, we sometimes recommend variable-speed operation,” Bassett notes. “It helps mask the engine sound under wind and road noise, making the experience more natural for drivers.”

Efficiency, cost, package, and NVH – those are the key criteria. Their importance varies by region. In China, efficiency is king. In Europe, NVH is a bigger concern

Fast development to be production-ready

As Bassett noted above, two other important criteria are rapid development cycles, and manufacturability.

Mahle employs advanced digital simulation tools and AI-driven modelling to compress development timelines. This accelerated development hinges on confidence in simulation accuracy. “We aim to get very close to the final production design before building anything physical,” he adds. This includes efficiency mapping and emissions modelling, often done on engine dynamometers to ensure compatibility with generator systems and optimal performance.

Bassett also stresses the importance of manufacturability. While performance and packaging are essential, the engine must also be cost-effective to produce at scale. “Efficiency, cost, package, and NVH – those are the key criteria. Their importance varies by region. In China, efficiency is king. In Europe, NVH is a bigger concern,” he says.

Mahle also assists with generator integration but typically hands off at the crankshaft. “We develop and validate the engine’s efficiency independently, but we’re involved in coupling and integration where needed,” he notes.

Alternative fuels and hybridisation

Emphasising the growing importance of alternative fuels and hybrid systems as crucial solutions with long-term relevance, Bassett confirms that Mahle is actively developing clean-sheet hydrogen internal combustion engines (ICEs), particularly for commercial vehicles. “We’re seeing interest in hydrogen for heavy goods vehicles,” he says. “A more pent-roof style combustion chamber, as you'd have in a gasoline engine, works better with hydrogen than traditional diesel swirl systems.” Hydrogen is attractive because of its near-zero tailpipe emissions, though it still faces infrastructure and legislative challenges. “It’s close to zero, but not absolute – there’s still a small amount of oil consumed, and that’s enough for some regulators to push back.”

Ammonia is another area of exploration – particularly for marine applications – though it's still early days. Other fuels like ethanol are also gaining attention, especially in international markets with supportive policy frameworks. However, gasoline remains the default choice for short- to medium-term range extender programs, due to existing infrastructure and known combustion behaviour.

In parallel, hybridisation – especially plug-in hybrids (PHEVs) – continues to gain traction. Bassett argues that PHEVs have been unfairly criticised due to tax-incentivised misuse rather than technical shortcomings. “People didn’t plug them in,” he said, referencing early models with limited electric range. But this is changing. “Next-generation PHEVs with 70–80 miles of electric range give people more reason to plug in, and that makes a big difference.”

Mahle has worked on several hybrid development projects and is a strong advocate of optimising ICE components specifically for hybrid applications. “As you increase the electric capability and battery size, you can actually drive down the cost and complexity of the combustion engine,” he explains. “You can take full advantage of the electric side and simplify the engine.”

Bassett also notes that hybrid and range extender systems will play a vital role for the next decade or two as the EV charging infrastructure scales up. “It’s a long stopgap – 10 to 20 years at least. Until charging is reliable and accessible everywhere, these technologies are essential,” he said. “You’ll still have pinch points where charging demand exceeds supply. Having an alternative propulsion source gives people confidence.”

From a manufacturing standpoint, the push for multi-fuel and hybrid-capable platforms has become more feasible with modern flexible production lines. “It used to be a nightmare adapting platforms,” Bassett noted. “Now with more automation and platform sharing, the integration challenges are more manageable.”