SSAB and Gestamp forge automotive sustainability partnership for fossil-free steel

Leading Swedish steel producer, SSAB, and Spanish metal component supplier, Gestamp, partner to transform automotive steel with sustainability and performance at its core.

Swedish steel producer, SSAB, has partnered with Spanish tier-one automotive supplier, Gestamp, to provide fossil-free steel solutions for body-in-white and chassis systems in the automotive industry.

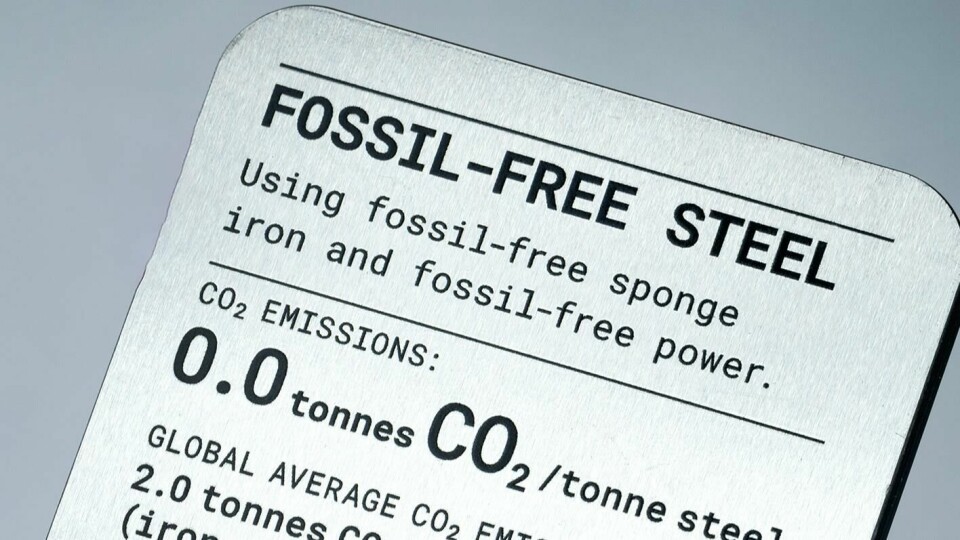

Recognised for its commitment to transforming steelmaking processes, specialised steel producer, SSAB, is set to introduce fossil-free steel to the market on a commercial scale by 2026. The company also aims to significantly reduce carbon dioxide emissions from its own operations by around 2030.

The production of fossil-free steel by SSAB involves a virtually carbon-neutral process, where the primary by-product is water. Notably, coking coal, traditionally used in iron ore-based steel production, will be replaced with fossil-free electricity and hydrogen, underlining the company’s resolute commitment to sustainability and environmental responsibility.

“These advancements are pivotal in our pursuit of safer, lighter vehicles, ultimately resulting in reduced energy consumption and a diminished environmental impact.”

Spanish multinational, Gestamp, is a global expert in the design, development and production of metal components for major automotive manufacturers. Its products are characterised by innovative design principles that enable the creation of lighter, safer vehicles, resulting in reduced energy consumption and a reduced environmental footprint.

The company’s expertise extends across the domains of Body-in-White (BiW), chassis, and automotive mechanisms. The multinational operates in 24 countries and has 115 production facilities (including five under construction), 13 dedicated R&D centres and a global workforce of nearly 43,000 employees.

SSAB and Gestamp already making strides towards sustainable steel

The two companies have already begun making strides towards sustainability in the industry. Gestamp recently partnered with the European division of ArcelorMittal in an agreement aimed at enhancing scrap steel utilisation across the automotive manufacturing sector.

”Together, we will provide invaluable support to the automotive industry, meeting the ever-increasing demand for substantial CO2 reductions from both manufacturers and consumers.”

SSAB has also already taken several significant steps in developing fossil-free steel to meet the automotive industry’s demand for sustainability. The company has several initiatives aimed at reducing CO2 emissions in steel production and enhancing supply chain transparency, positioning SSAB to support the industry’s sustainability goals.

Owing to the global reach and expertise of the two companies, this latest partnership marks a significant step toward achieving a more sustainable, eco-friendly and innovative automotive manufacturing landscape.

With fossil-free steel at its core, the collaboration paves the way for the creation of safer, lighter vehicles with a significantly reduced carbon footprint, ultimately benefiting both industry and environment.

Safer, lighter, sustainable vehicles

Javier Imaz, Chief Procurement Officer at Gestamp, commented: “The fossil-free steel partnership with SSAB will significantly enhance Gestamp’s ability to develop innovative and sustainable automotive components. These advancements are pivotal in our pursuit of safer, lighter vehicles, ultimately resulting in reduced energy consumption and a diminished environmental impact. This collaboration will also play a pivotal role in helping us achieve our sustainability goals.”

Tony Harris, Head of Sales and Business Development at SSAB Europe, added: “We are thrilled to welcome Gestamp as an SSAB Fossil-free steel partner.

“Together, we will provide invaluable support to the automotive industry, meeting the ever-increasing demand for substantial CO2 reductions from both manufacturers and consumers. Our joint efforts will lead to the production of more environmentally friendly vehicles.”

The agreement signals a new phase in the long-standing collaboration between Gestamp and SSAB, which encompasses a wide array of initiatives across the value chain.

These initiatives span across sales and production, through to rigorous testing, highlighting an example of inter-company cooperation within the steel products sector, with a common vision for sustainability.