Siemens smart data solutions for sustainability

Smart energy and data solutions power shift to green auto manufacturing

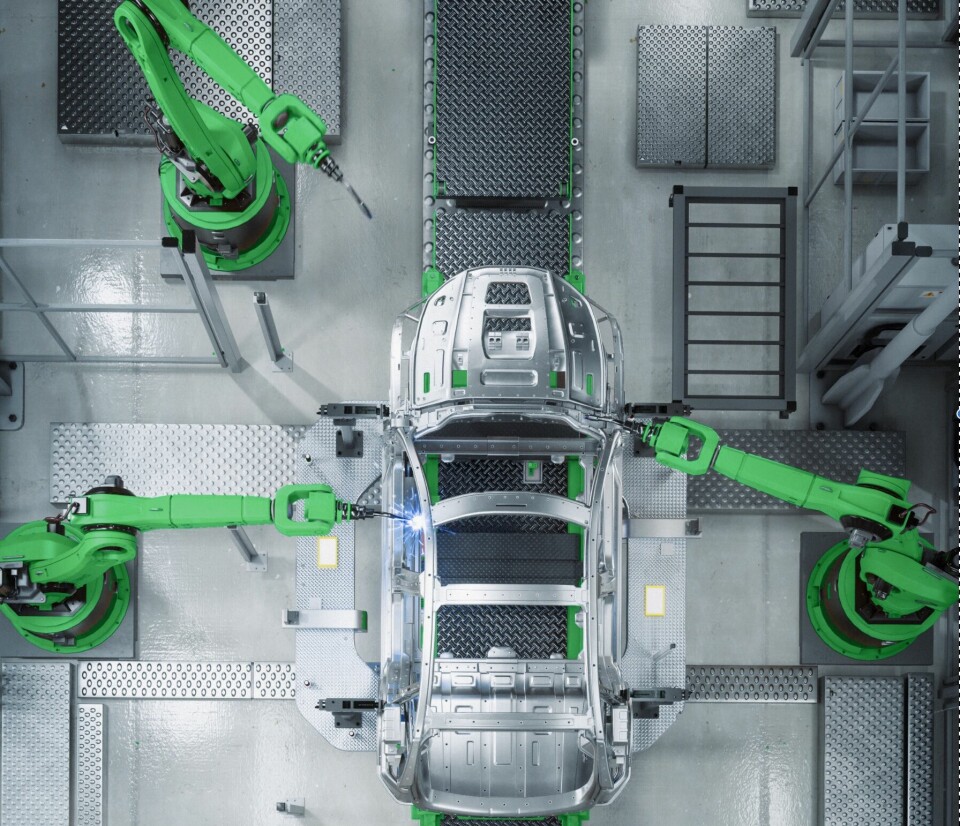

As sustainability has become a priority for global automotive manufacturing, OEMs and suppliers are adopting digital energy management systems to track, reduce and optimise energy consumption and carbon emissions across plants and supply chains. Siemens is helping to lead this transformation, enabling measurable reductions in CO₂ and operational gains, especially in paintshops and bodyshops.

With emissions regulations tightening and climate targets accelerating, the automotive industry is being pushed to decarbonise not only the vehicles it produces, but also the way those vehicles are manufactured. From electrification to circular material use, the pressure to decouple production from environmental impact is reshaping factory strategies worldwide.

One of the most effective levers available to manufacturers is improving energy efficiency across operations, particularly by increasing transparency of usage data, introducing smart controls, and reducing standby waste and energy consumption during downtime.

Siemens is addressing these challenges through its portfolio of digital energy management systems, edge connectivity tools, and scalable, standardised architectures that help plants cut consumption, costs, and carbon emissions without sacrificing performance.

Measuring and managing energy performance at scale

Energy management in automotive production remains highly complex and variable, often lacking visibility at the machine, process or cell level. Bodyshops and paintshops are among the highest consumers of energy with paintshops alone accounting for 45% to 70% of plant energy use.

Identifying inefficiencies here can deliver rapid sustainability wins, but historically this has been difficult due to fragmented or missing data. Siemens offers an integrated approach to energy management, deploying sensors, real-time data analytics and cloud platforms across the shopfloor.

These solutions enable manufacturers to monitor energy flows, visualise consumption trends, and benchmark performance across global operations. Siemens’ technologies support strategic decisions around load management, process tuning and investment planning while also helping customers align with Scope 1 (direct emissions released from a company's own operations and assets) and Scope 2 (indirect emissions from the generation of purchased energy) emissions targets.

Reducing idle energy waste with Siemens Profienergy

A significant yet often overlooked source of energy waste in automotive plants is machinery running during production breaks or idle periods. In bodyshops, robots are typically left powered on through weekends or maintenance cycles to avoid time consuming‑ restarts. But this comes at a high energy and emissions cost.

Siemens’ Profienergy protocol addresses this challenge by enabling intelligent standby control for robots and other equipment. Built to integrate seamlessly with the Profinet network, Profienergy allows machines to enter lowpower‑ ‘sleep’ modes during scheduled or detected downtime without the risk of failed restarts.

The solution has proven especially effective in reducing the CO₂ footprint of robot cells, while preserving plant availability and responsiveness. In one example, Siemens helped a major automotive manufacturer save more than 800 metric tons of CO₂ annually by applying Profienergy to implement automated standby modes across bodyshop robot cells, all without affecting shift plan flexibility or operational continuity.

Carbon transparency across the supply chain with Catena‑X

With as much as 90% of automotive CO₂ emissions occurring in the supply chain, improving transparency across Tier 1 partners is becoming essential.

Siemens supports this through its involvement in Catena-X‑, a decentralised data-sharing network that enables OEMs, suppliers, and recyclers to exchange verifiable Product Carbon Footprint (PCF) data.

By aligning to common data standards and enabling real-time PCF tracking, Siemens helps manufacturers visualise emissions hotspots, comply with regulatory frameworks, and collaborate across the value chain to reduce embedded carbon.

Its IT/OT-integrated platforms and cloud-based hubs support PCF aggregation and traceability, providing a foundation for dynamic sustainability management.

Supporting circularity with the Siemens Battery Passport

In the EV value chain, battery production presents a major sustainability challenge – from mineral sourcing and emissions-heavy manufacturing to safety, reuse and recycling.

Siemens has developed the Battery Passport, a digital solution that enables end-to-end traceability of battery attributes and carbon footprint across production, use and reuse.

This solution not only ensures compliance with the EU Battery Directive and Catena-X requirements but also aids OEMs and recyclers in optimising battery lifecycles and resource circularity.

By aligning upstream suppliers with open DPP 4.0 architecture, Siemens provides the tools to improve transparency, performance, and ethical sourcing across the battery ecosystem.

Digital transformation for sustainable manufacturing

As manufacturers ramp up efforts to decarbonise production, Siemens technologies are emerging as critical enablers of scalable and measurable impact.

From real-time energy visualisation and intelligent robot standby to supply chain emissions tracking and battery lifecycle monitoring, Siemens provides an integrated suite of solutions to support factory-wide and cross-industry sustainability goals.

Smart energy strategies are not only helping OEMs meet emissions targets, they are also supporting cost efficiency, productivity and operational resilience in an increasingly competitive landscape.

For the automotive industry, the path to sustainability runs through the factory floor, and Siemens is helping lead the way through digital transparency, standardised architectures and industry collaboration.