Watch: Keeping pace with battery demand and technology

Rising costs and fast-changing battery technology will make it hard to meet EV targets, but localisation and new business models can mitigate issues, according to Automotive Cells Company’s Francisco Carranza and Airbus’s Greg Ombach.

Related video

-

Watch: Partnerships to establish the battery value chain

-

Watch: How JLR Is futureproofing production and skills

-

Video: Opel’s Bilyana Stern on leadership, logistics and building resilience at Stellantis

-

Video: BMW’s Dr. Michael Nikolaides on AI, robotics, and resilience

-

Video: Arno Güllering on transforming Dräxlmaier’s global production

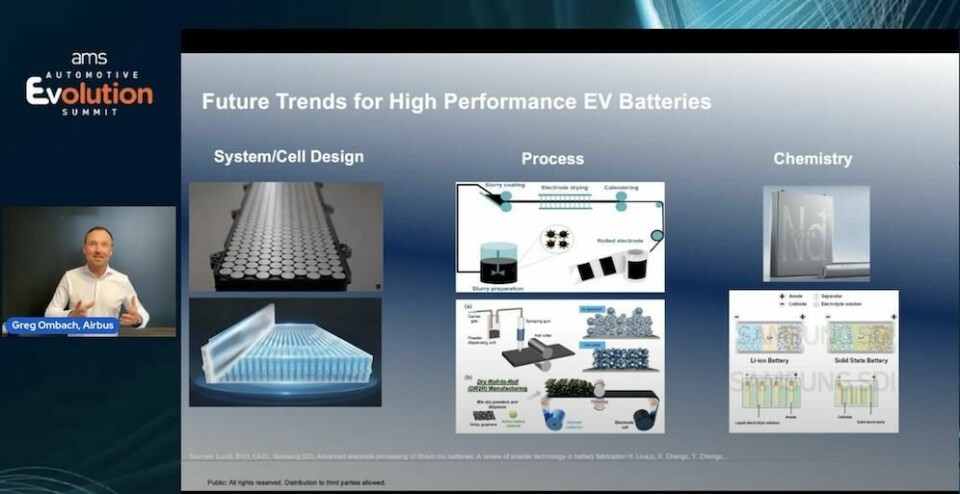

OEMs are accelerating the transition from ICE to electrification with large investments in start-ups, battery technology, production, upskilling, and smart factories to meet these electric vehicle commitments. But battery technology and chemistry are changing even faster than manufacturers can invest in them, while OEMs, tier-1 suppliers and battery cell producers are all vying to insource key areas of battery manufacturing and add more value, especially as input costs are rising fast.

In this session, hear from technology futurist Greg Ombach and Francisco Carranza from Automotive Cells Company (ACC) – jointly owned by Stellantis, Mercedes-Benz and Total – on how battery technology across the automotive and aerospace sectors will impact on production processes and the value chain. Wath the video and learn more about:

- What changing battery technology, from LFP to sodium to solid state, will mean for battery manufacturing

- Who will be the winners and losers in the manufacturing value chain?

- Opportunities in design for remanufacturing, design for recycling & design for circularity

- What to expect from EV and battery factories of the future

Hosted by Christopher Ludwig, editor-in-chief, AMS and Ultima Media