Making shopfloor management an asset in the smart factory

No matter how comprehensive the digitalisation and automation, the human factor still drives the modern smart factory. And yet, the intersection of man and machine, the shopfloor management, needs a rethink to become an asset in the data driven production line. Report by Chris Löwer

The smart factory may be highly automated, but on occasion, things will still go wrong and an intervention by staff will be needed to control the disruption and plan ahead. Except, it will be in an environment that is much more complex than it used to be.

This means that even in smart automobile production, shopfloor management (SFM) will remain a central topic for management to optimise process and staff management. Management needs to be in the factory hall, coordinating with the workers if they want to be able to react quickly to issues and improve processes. But for this to be possible, shop floor management needs to be up to date with the requirements of smart production.

A new way of thinking on the shopfloor

“Foremen and executives are increasingly becoming data managers,” says Heiko Weber, partner at Berylls Strategy Advisors. They have to identify the right information to extract from data lakes and industrial clouds – the data that will actually help to optimise production. That involves being able to ask the right questions. “It’s a whole new way of thinking,” Weber emphasises. But no matter how data-driven the SFM will be in the future, one thing will remain constant: People will lead people, just differently than before. You can learn how to work competently with large amounts of data. What is harder to pick up is a feeling for who to deploy where in an increasingly agile working environment in the smart factory.

“Leadership behaviour will have to change when hierarchies are levelled. Managers should see themselves as coaches in production”

That sense for people will be all the more important, because Weber is convinced that traditional hierarchies will increasingly dissolve. “Not least because employees on the assembly line may be more digitally versed in their area than the foreman.” Therefore, they and other managers should be prepared to learn from workers. “Leadership behaviour will have to change when hierarchies are levelled,” says Ralf Bechmann, partner at ROI Management Consulting. “Managers should see themselves as coaches in production.” For that to be a success, they will need a certain mental flexibility, as well as be prepared to figure out and use all the possibilities of a data-oriented SFM.

Flexibility is also required in other respects, for example when working with cobots. If a production robot decides to go on strike today, a maintenance technician is called in to help, who will then talk to those responsible for maintenance and planning and find a way to ensure the same issue doesn’t occur again. However, if workers and robots work together, the human will have to intervene directly. They have to take a certain amount of responsibility for the machine, and that will require much more know-how in the workforce, says Weber.

Acquiring this expertise and making it clear who is responsible for what and when, and ensuring information gets to those who need it, will be one of the central tasks of a shopfloor manager. Those who fail to master this new way of working and just stick to the traditional triad of instruction, classic division of labour and control will in the future, struggle to lead their team in regards to smart production processes.

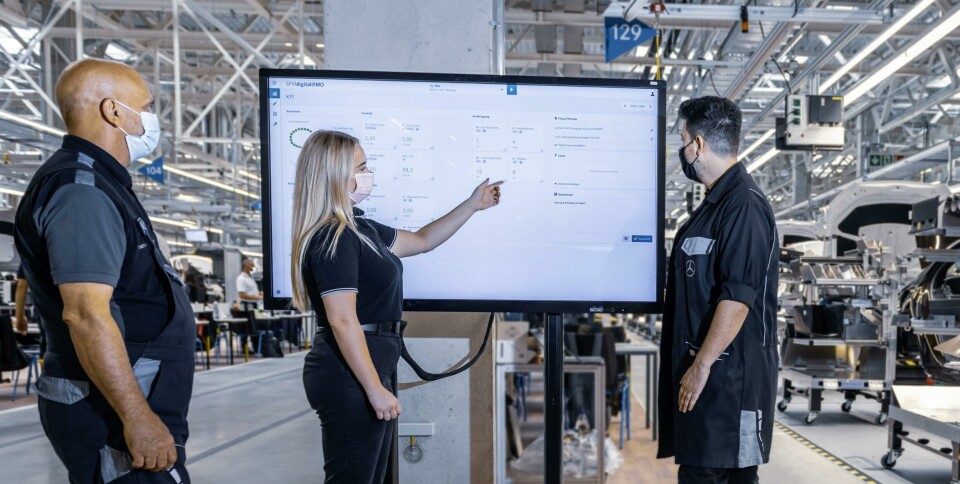

Just as important for a successful transformation is a corporate culture that thrives on courage, curiosity, the will to learn and tolerance for mistakes, explains Christian von Stengel, CEO of Germanedge. “In such an environment it becomes easier to venture into new territory. When the organisation goes a step further and puts people at the heart of operations – not just strategically, but also with the help of technology like intuitive user interfaces, then the transformation can really take hold.” The results will be tangible, with fewer process to manually control and less paperwork.

“It is crucial that data from different sources can be linked and that historical data from the SFM is available at all times. This makes it clearer when events are connected makes finding solutions quicker and more effective”

A good example of this would be engine assembly: The enormous amounts of data that accumulate in end-of-line testing could be analysed faster and better in the future using an AI tool that immediately sends the analysis to a worker’s smartphone. Here too, SFM will play a new, essential role. When regular troubleshooting and predictive maintenance is taken over by artificially intelligent systems, the employees will need to understand how the underlying algorithms work and where their limits lie. At the same time, it is important to control the flood of information and not to stress the employees with a constant bombardment on their screens.

Why digital platform solutions are needed in manufacturing

Von Stengel reckons digital SFM solutions will play a key role: “It is crucial that data from different sources can be linked and that historical data from the SFM is available at all times.” This way, all relevant information, including from production, employees and events during a shift is continuously recorded, historised and made available in real time: “This makes it clearer when events are connected makes finding solutions quicker and more effective.”

Properly organising the flow of information on the shop floor can be achieved through suitable platform software, explains von Stengel: “The reason for this is obvious: manually collecting and communicating information leaves the door open for errors and there is no chance of doing it in real time.”

To make matters worse, the old-fashioned way only records the current state of operations. “But from the moment where historical data can be used for things like troubleshooting, decision making is supercharged,” says von Stengel. And AI or not, in that decision-making process, the final word will always lie with people.

For Bechmann, the future of SFM therefore lies in the symbiosis of cooperative leadership that is close to the people in the factory hall on the one hand, and on the other with digital tools that provide meaningful support without being overwhelming. For him, one thing is clear: “The production environment and collaboration as we know it today will change fundamentally.” For everyone – from the worker to the manager.