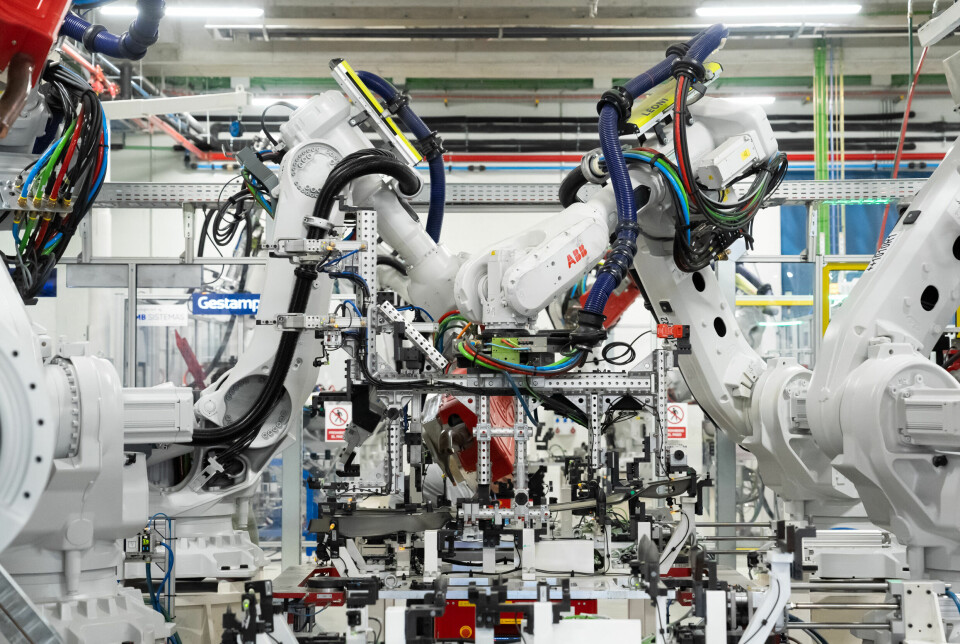

Gestamp boosts production flexibility

Gestamp’s digital pathway to flexible, efficient manufacturing

Jorge Vázquez Cancela, I4.0 Virtual Factory Project Management at Gestamp, discusses how the company has been developing its approach to Industry 4.0 principles and the integration of digital tools into production operations to boost efficiency and flexibility

How does Gestamp manage/share development/process data across the 115 plants worldwide Loire and Edscha divisions? How is Industry 4.0 (I4.0) being implemented in the 24 countries where Gestamp operates and in the company's subsidiaries?

Gestamp has undergone a complete, global transformation in digitalisation and Industrial IoT within the framework of I4.0. This evolution has been driven by the development of diversified IoT connection standards tailored to different technologies and processes, covering connectivity, cybersecurity, network segmentation, and an edge layer at plant level. Using big data and artificial intelligence, advanced analytical rules and models have been created to conceptualise a fully digital and intelligent factory.

Massive IoT deployment involves integrating both simple and advanced IoT devices, enabling comprehensive and detailed monitoring of each technology and process within a plant. To ensure global rollout and scalable development of I4.0 at Gestamp, a federated framework has been key in building a coordinated ecosystem. Concretely, for example, there is a person in each region in charge of the Digitalisation roadmap of the plants of that region.

Additionally, the integration of generative machine learning models, image recognition, and variable-based models is supported by the standards developed in the conceptualisation of the digital and intelligent factory.

Has Gestamp seen greater efficiencies on the shopfloor resulting the deployment of digital tools?

We have been working on I4.0 since 2016. Throughout this digitalisation journey, we have launched more than 400 I4.0 projects, each of which has taught us something valuable to advance efficiency and operational excellence. In total, to date, we have more than 70 digitalised production plants with all the main technologies connected and more than 10,000 AI rules applied.

Concretely, one of the greater efficiencies that we have achieved is through the development of a Digital Twin that virtualises the operations of the plant, to monitor and predict behaviours that help us to recognise opportunities to improve operations.

Another important example of this progress is in the company’s energy efficiency initiatives across production and operations. Since 2016, Gestamp’s Energy Efficiency department has been focussing on reducing the energy consumption of its operations to be as efficient as possible. Thanks to a global initiative to optimise and reduce energy use, the consumption of gas and electricity by equipment in production plants is monitored to model their performance. Based on these consumption patterns, algorithms are created to identify, quantify, and report deviations. This effort has been rewarded with a total savings of 107.535 tons of CO₂ between 2016 and 2024.

We’re seeing a greater emphasis on the human-centric approach to the digitalisation of production operations. Is this also a focus for Gestamp and how this is being implemented?

From Gestamp’s point of view, technology must follow a human-centric approach. That’s to say, the company’s value proposition lies on the goal of working every day for safer and more sustainable mobility. To make the next generation of mobility solutions a reality. Therefore, digital tools, such as AI, technology and innovation must always be aligned with that purpose: achieving a better mobility for society and the planet.

This purpose is reflected in our commitment to electrification, technology and innovation, ESG, operational excellence and, at the foundation of all these, talent.

So, digitalisation is not just about technology — it is always human-centric. As part of our ESG strategy, Gestamp promotes upskilling and reskilling programmes (both for internal and new talent) to ensure our teams are prepared for the digital transition.

Do you see AI supported, real-time analytics as a real breakthrough for shopfloor operations?

Generative AI is a clear lever that can, for example, increase productivity by reducing repetitive tasks on the production plants or, thanks to real-time analytics, detect and predict errors in the production chain and help our people choose the best solution — striking a balance between automation and human decision-making, with a focus on quality and operational excellence. In other words: competitiveness.

In fact, we have more than 350 installations connected following our standard in our IoT platform, and we have deployed our real-time analytics. From that we are starting to create and develop AI models that will help us to boost the optimisation of the process.

Automation is becoming smarter and capable of performing complex assembly tasks. Does Gestamp see more opportunities for human-machine collaboration with this development?

Thanks to a fair digital transition and the smooth integration of automation into existing systems, we achieve a balance between automation and human participation.

In this way, we can preserve the creativity and adaptability of our teams, while automating repetitive tasks and enhancing efficiency.

On this path, Gestamp is driving innovation within a culture of continuous improvement, where enabling technologies – such as AI – support our teams in identifying new technological opportunities.

With 5G networked factories connected and AI supported, real-time data do you see AGVs and AMRs being deployed more widely in a greater range of roles?

Our point of view is that the implementation of AGVs is a must, and we have a strategic plan to deploy these widely, but currently we cannot link a 5G network or AI implementation to the deployment of the AGVs.

AGVs (or AMRs – Autonomous Mobile Robots) play a key role in the new smart and flexible industrial ecosystem that Gestamp is developing. Interaction between equipment, products, and people is already a reality through movement. Thanks to the digitalisation of the plant and the analysis of real-time data, there is a continuous flow of movements and actions aligned with the previously defined production plan.

This flow is always managed in real time, optimising routes, circuits, and traffic within the production plant. Such efficiency is essential to the flexible manufacturing concept and represents a great opportunity to be at the forefront of the industry.

With this flexible (and intelligent) manufacturing concept, Gestamp addresses the major challenges of the automotive industry: ESG, electrification (due to uncertainty regarding volumes), and industrial transformation driven by digitalisation. This concept offers the possibility of manufacturing different references with different technologies in the same production facility. Therefore, supports the adaptability to market changes.

Do you see the shopfloor teams playing an important role in the security of factory digital networks?

Internal talent is key in this era of transformation, because Gestamp’s talent holds the broadest know-how of the business — each person in their own area of specialisation.

Therefore, it is essential to develop upskilling and reskilling programmes to keep our teams at the forefront of the industry, especially in digital tools that help preserve, for example, the security of factory systems.

Additionally, attracting new talent with the necessary skills in technical maintenance for shop floor tasks, programming, data science, etc., is equally important.

The reality is that, at this moment, shopfloor teams are the main actors in the development of the tools. They are the ones that define the requirements and analyse the developments.

In conclusion, investing in global learning is just as important as investing in innovation, as both pillars are the driving force behind a state-of-the-art company.