Smart Quality Control

Augmented Reality transforms automotive production quality control and efficiency

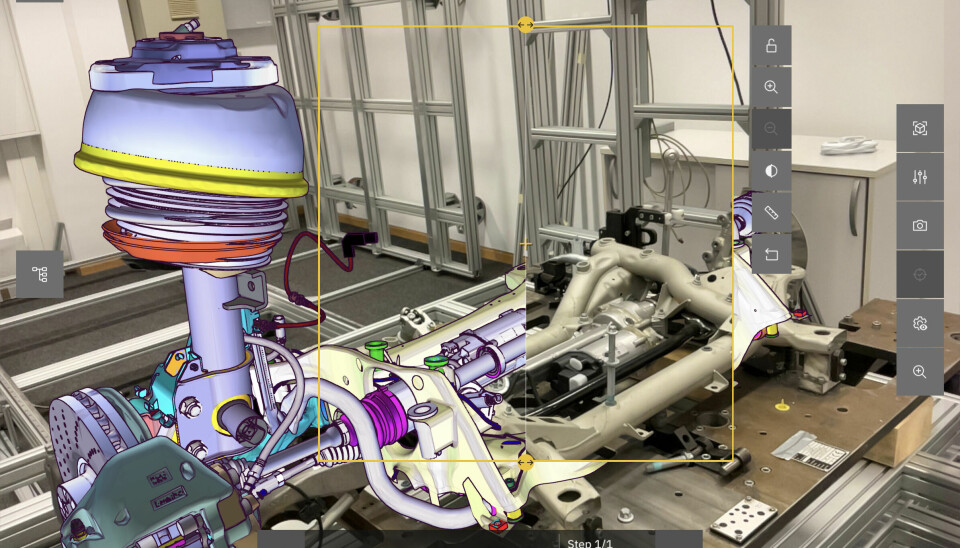

Visometry's Twyn AR solution boosts Quality Control, accelerates vehicle production and enhances Human-Machine collaboration on the shop floor

Modern manufacturing methods demand advanced solutions to keep pace with new processes. As the role of automation continues to grow, inspection protocols must work to enhance human capabilities and enable operators to react quickly. While robotics and automated machinery can streamline production, these systems are not infallible.

We hear a lot about the potential of AI technology but Florian Schmitt, Product Manager for Twyn at Visometry argues AR is the key to unlocking operational efficiencies and flexible inspection processes.

Quality inspection through Augmented Reality: Reducing inspection time by ≤80%

Discussing Twyn, Visometry’s AR platform, Schmitt says, “automotive manufacturers use Twyn to inspect incoming and outgoing goods, such as parts, pre-assemblies, or logistic racks, by overlaying CAD data directly on the real object.

“Unlike traditional methods that rely on 3D scanners or off-site measuring stations, Twyn enables fast, on-site validation of completeness and geometry. This reduces inspection time by up to 80% and helps detect deviations earlier. As a result, error rates drop by up to 90%, significantly improving quality workflows under high time pressure.”

Thanks to the platform’s model-based tracking system, it has good tolerance for various shopfloor conditions including reflective surfaces, poor lighting or comprehending large components which are only partially visible to the camera.

Improving stability for complex components

Schmitt adds, “the ‘Stationary Object’ mode, introduced in release 2.3, further improves stability for complex components by using the iPad’s SLAM sensors, even when walking around or inspecting low-structure areas. A built-in tracking cache stores anchor poses from previous sessions to speed up initialisation and maintain consistent overlays, even in constrained environments.”

Launched in 2021, the system has already been successfully implemented across various industries including automotive, rail, agriculture, welding, and toolmaking. Well-known automotive manufacturers, such as Porsche, Skoda, Daimler or Suzuki, are among Twyn’s users.

With AR overlays, CAD data is projected directly onto the body shell, allowing inspectors to identify missing or misaligned parts instantly. This not only speeds up inspection but also reduces errors and simplifies the process across teams, making it ideal for pilot builds and high-variant production

One typical application in the automotive sector involves replacing costly hardware templates used to verify joining elements such as bolts or studs. With Twyn, AR overlays assist in the inspection of welding spots, bolts, and fasteners, by combining visual guidance with semi-automated evaluation. Predefined viewpoints guide workers to each inspection point, where CAD data is precisely aligned with the physical part. Twyn is also used as a digital guide during assembly and quality assurance processes.

For example, it supports locating missing components like bolts or welds when discrepancies are detected. In highly time-sensitive workflows, workers benefit from visual cues that lead them to the exact location requiring attention, minimising manual search time and reducing costly delays or reworks.

Body-in-white, AR overlays and CAD data

For body-in white inspections, Schmitt explains, “Twyn addresses key pain points by replacing physical templates, measuring arms, and 2D drawings – tools that are often slow, rigid, and prone to misinterpretation.

“With AR overlays, CAD data is projected directly onto the body shell, allowing inspectors to identify missing or misaligned parts instantly. This not only speeds up inspection but also reduces errors and simplifies the process across teams, making it ideal for pilot builds and high-variant production.”

The adaptability of the platform allows it to be used as a design tool for pre-series and prototype validation. Before the final design is complete, Schmitt says, “in grey zones, Twyn allows teams to review and simulate design revisions directly on physical mockups using virtual overlays. This eliminates the need for costly clay models and enables collaborative evaluation between design, manufacturing and quality assurance.”

Similarly, Twyn’s AR functionality can be leveraged to validate jigs and fixtures. In the interest of identifying inaccuracies as early as possible to minimise disruption later in the manufacturing process, the tool facilitates quick detection of unintended changes.

“By overlaying CAD data onto physical tooling structures, teams can check alignments, completeness, reference points, and clearances early on. This is particularly helpful when positioning elements like clamps or locating pins, where even small deviations, such as shifted hole patterns on a master jig, can lead to issues during part loading or clamping,” Schmitt explains. “Twyn ensures that all elements are mounted exactly as designed, reducing the risk of fitment problems.”

Twyn's intuitive studio hub designed for technicians, engineers and more

With any system like this, the success of its implementation is, in part, linked to the operator’s ability to maximise the functionality of the software. When designing Twyn, Visometry considered this from the perspective of inputting CAD data into the system as well as ease of use for the technician on the factory floor.

Twyn Studio is a hub for importing and manipulating CAD data. The platform accepts all industrial CAD formats and allows manufacturers to upload existing inspection routines from spreadsheets.

“Twyn was designed with usability in mind. Most technicians and engineers are productive with the system after a short introduction. The intuitive interface, markerless tracking, and guided inspection views eliminate the need for extensive training or CAD expertise. This accessibility significantly reduces onboarding costs and supports scalable deployment in production environments,” Schmitt says.

The future of Twyn: Smarter, more integrated manufacturing

Looking ahead to future iterations of Twyn, Schmitt concludes, “as manufacturing becomes more digital and competitive, Twyn is evolving into a smarter, more integrated platform. Support for mobile device management (MDM) enables secure deployment across global plants. Planned machine learning features will further automate inspections, especially for welds, bolts, and geometry checks, boosting speed and precision.

“At the same time, the introduction of a CLI interface will allow seamless integration with PLM and PDM environments. This ensures that inspection workflows can be connected to engineering data and product revisions, enabling fully traceable and scalable quality processes. Twyn is helping manufacturers manage growing complexity, variant pressure, and tight cycle times with a visual, flexible inspection system.”