Charpy test for laser welded blanks

Accelerating Development with Charpy: A Faster Path to Crashworthy Laser Welded Blanks

Tommy E. Yoshimura, Director of Product and Solution Development at ArcelorMittal Tailored Blanks Europe, explains how ArcelorMittal’s pioneering Charpy-based testing protocol for hot-stamped laser welded blanks ensures weld integrity in real-world crash scenarios

In today’s race to develop lighter, safer vehicles under increasingly tight timelines, carmakers need faster, more predictive tools to validate crashworthiness. ArcelorMittal’s innovative adaptation of the Charpy V-notch test for hot-stamped laser welded blanks (LWBs) provides exactly that — a dynamic, development-stage solution that enables car manufacturers to make confident decisions in days instead of months.

For ArcelorMittal, this means going beyond conventional tests. By replacing lengthy crash simulations and complex test loops with a robust, production-ready methodology, the Charpy test empowers engineers to identify brittle welds early, optimise designs faster, and bring new models to market sooner, without compromising safety — supporting advanced automotive steel solutions like ArcelorMittal Multi Part Integration® (MPI) whilst meeting the toughest safety standards.

Why conventional tests fall short

Traditionally, automotive suppliers have relied on quasi-static tensile tests, dynamic tensile tests, or full Omega section crash tests to assess the behavior of laser-welded blanks under crash conditions. While effective to some extent, these methods can be time-consuming and costly. In some cases, a full dynamic crash test can take up to six months to deliver results, a bottleneck when carmakers are under pressure to shorten development cycles and launch new models faster, often in less than 24 months.

Moreover, while tensile tests confirm the strength of the base material, they can miss hidden weld defects or fail to capture how a weld behaves under sudden, high-speed impact. This is especially important for hot-stamped steels like Usibor® and Ductibor®, which rely on protective AlSi coatings . If these coatings are not properly managed during welding, the excess of aluminum can be concentrated in the weld pool — a risk that can embrittle the seam and compromise crash performance.

Tensile tests can miss hidden weld defects or fail to capture how a weld behaves under sudden, high-speed impact

A smarter solution: Partial ablation and Charpy impact testing

To tackle this, ArcelorMittal’s R&D teams introduced partial ablation: a robust and controlled process that removes a narrow strip of AlSi coating along the weld path. This reduces any detrimental effect related to aluminum contamination, maintaining the weld ductility while preserving corrosion resistance in the rest of the part.

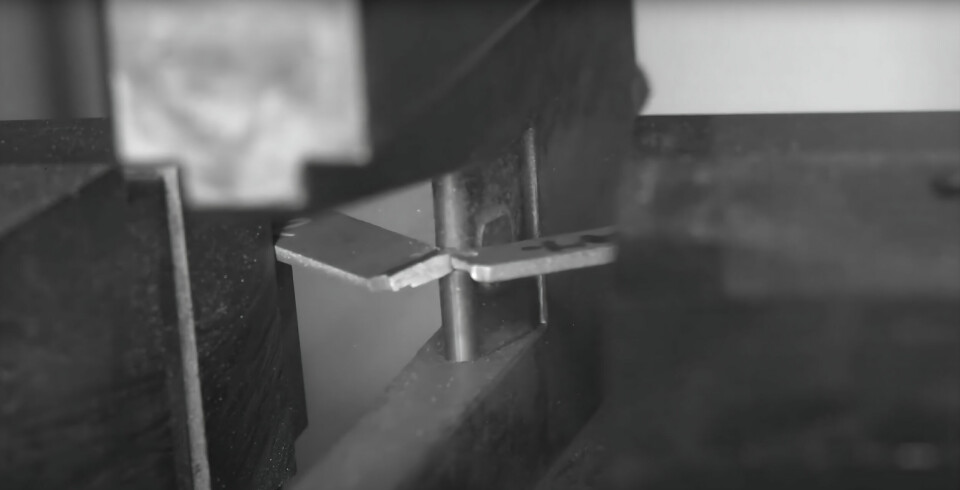

But proving that these welds will hold up under crash loads required a new approach. Enter Charpy V-notch test — a universal and dynamic impact test traditionally used for thicker heavy plates, but now tailored for today’s thin-gauge LWBs.

This tailored test measures the energy absorbed by a notched sample when struck at high speed, directly replicating the sudden deformation forces experienced in a crash. By setting clear thresholds it can quickly distinguish brittle welds from ductile, crashworthy ones.

The Charpy test method directly replicates the sudden deformation forces experienced in a crash

A universal and robust methodology built for real production

The new Charpy methodology adapts standard ISO 148-1 and ASTM E23 procedures to suit welded blanks. It defines precise sample geometries, careful notch positioning, and tight tolerances on misalignment to ensure repeatable, reliable results. By applying this test at room temperature and low temperatures (as low as -50°C), this method validates that the LWBs deliver robust crashworthiness even in severe climates.

Charpy enables manufacturers to make faster, data-driven decisions and reduce validation timelines

The Charpy V-notch test is a universal and fair methodology that enables carmakers to validate weld integrity early in the development process, regardless of the welding method used. By combining this standardised test with robust coating strategies and advanced welding practices, manufacturers can make faster, data-driven decisions and reduce validation timelines. ArcelorMittal’s commitment to promoting this approach helps accelerate the development of the next generation of body-in-white, empowering carmakers to deliver lighter vehicles — without sacrificing safety or timelines.

Find out more by contacting ArcelorMittal, here.