McLaren Applied and Elaphe aim to boost EV performance

New partnership combines McLaren Applied’s next-generation inverter with Elaphe’s range of in-wheel motors

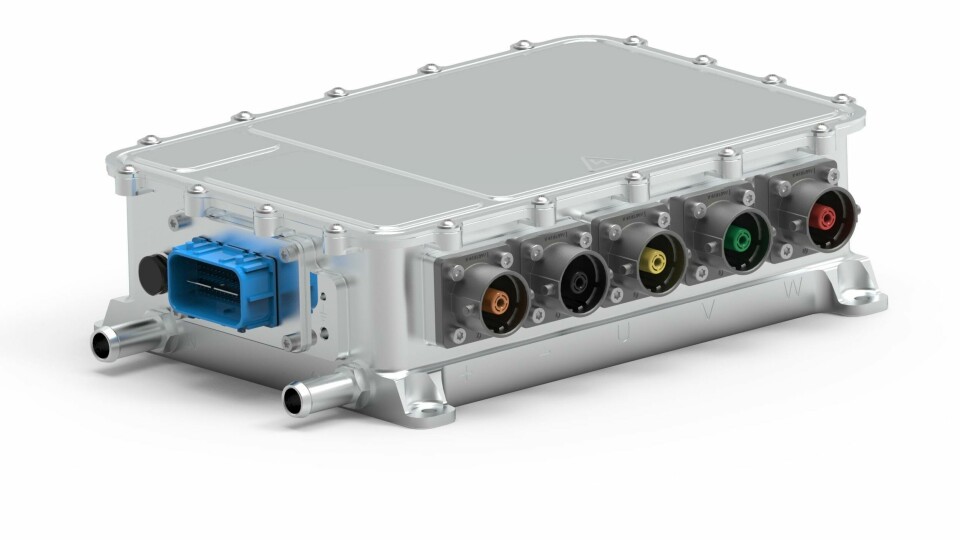

McLaren Applied is combining its next-generation IPG5 800V silicon carbide inverter with Elaphe’s range of in-wheel motors, which it’s claimed will create a highly efficient system that will offer enhance EV packaging, efficiency and driving dynamics.

“We believe efficiency and driving dynamics will play an important part in the next waves of electrification,” commented Stephen Lambert, Head of Electrification at McLaren Applied.

The company describes the first wave involving early pioneers of technology, the second, current wave marked by EVs becoming mainstream. The third stage is efficiency and, the company says, will see inverter technology rapidly adopt silicon carbide (SiC) semiconductors, especially in 800V architectures and vehicles that need longer range where efficient power electronics are key.

McLaren Applied’s belief is that the fourth stage will focus on drivability and adding character back into the powertrains of electric vehicles, improving driver engagement and differentiation from the competition. “High switching frequencies and the ability to control the drivetrain more sensitively enables you to start programming different characteristics into the drivetrain. With this, we can introduce character that some might say is lacking from EVs,” adds Lambert.