Coding & marking for the automotive industry

Linx Printing Technologies explores how effective coding and marking solutions can deliver important benefits throughout the vehicle manufacturing process

With a modern vehicle containing thousands of individual components, many needing to carry a specific part number, there is no room for error in the selection of coding and marking equipment. From suppliers manufacturing the smallest parts, to vehicle-makers relying on the correct coding for traceability throughout the assembly process and beyond, the inclusion of information which stays in place – whether on metal, rubber, plastic, glass, fabric or card – is a crucial part of the process.

In the UK alone, over 1.5m vehicles and 2.5m engines are produced each year, and car manufacturing volumes are predicted to reach a record high by 2017. Indeed, the UK Government has identified a £3 billion opportunity for domestic suppliers to provide parts to UK-based vehicle manufacturers. Furthermore, industry operating profit margins are predicted to grow to 8.1% in 2017-18 due to better stock controls, more efficient supply chain systems and more stable demand than during the previous five years.

It is against this background that the importance of robust coding for traceability and supply chain management becomes clear. Manufacturers are looking to global traceability and containment solutions to maximise their responsiveness and minimise the impact of vehicle recalls due to faulty parts, such as the 2013 recalls relating to Tataka airbags. The financial impact for the manufacturer of a defective part can be huge; not only recall costs, but perhaps also fines, loss of share value and reputational damage.

Coding can also help in the fight against counterfeit parts, at a time when an estimated $12 billion of global counterfeiting is linked to the automotive industry. Fake brake pads, tyres, suspension components, steering linkages and other accessories are being distributed universally and sold to consumers in increasing volumes.

The World Trade Organization (WTO) has highlighted areas where coding and marking can assist the battle against counterfeit parts, not only scannable barcodes but invisible anti-counterfeiting printing inks and even smartphone technology. These days, simply text messaging a product code to a specified number can allow end customers to confirm at the point of sale that a product is genuine.

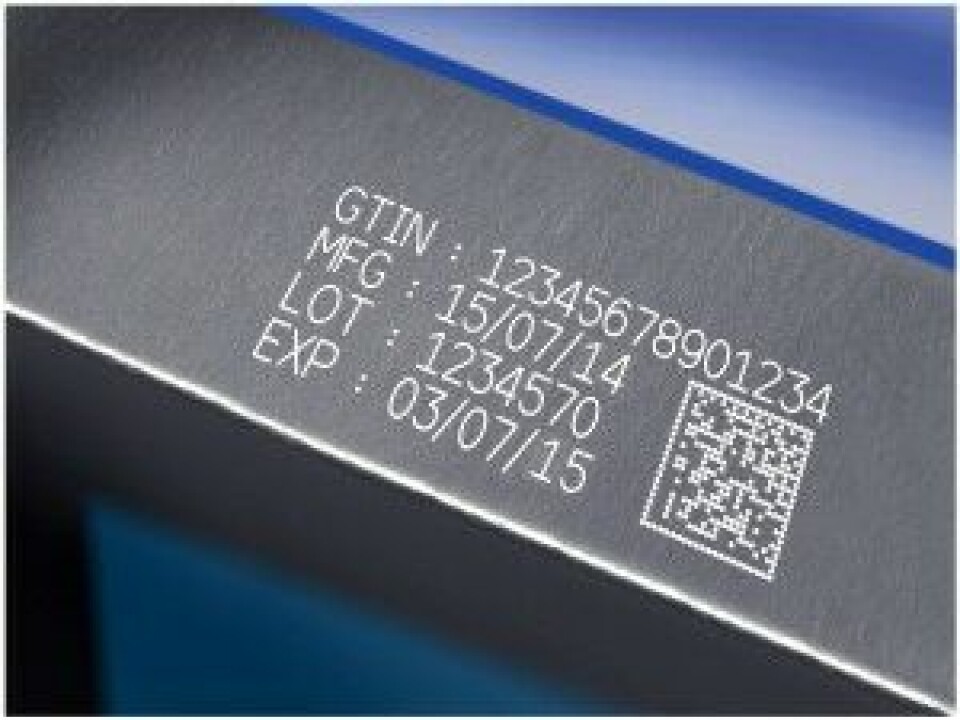

Direct part marking, combined with effective vision systems, can tackle all of the above issues and make the component traceability process both easy and reliable.

Complex coding requirements

In an industry which requires information to be printed onto individual components at various stages of the production process, coding and marking equipment must be able to comfortably meet the complex demands of automotive manufacturers. Robust coders must offer trouble-free integration into existing processes and thereafter operate reliably in challenging production environments.

Code functions can vary, too. Codes may need to be: removable for internal traceability; discreet for anti-counterfeiting purposes; or long-lasting to meet customer traceability requirements.

An effective coding solution, tailored to the manufacturer’s requirements, can help to facilitate smooth production and assembly processes, as well as helping vehicle manufacturers to deliver top-quality after-care to drivers. Whether for monitoring components through the assembly process, stock control or to meet customer expectations, codes that are durable, clear and accurate are a must.

Coding considerations

However, no two applications are exactly the same and the following are all factors to consider when selecting a coding solution:

- Code content – will increased code complexity such as additional lines of print, or printing in different orientations, be supported by the printer you choose, or will you need to purchase another printer?

- Substrate – consider the range of materials you need to code. Ensure that you have each of these sample-coded by the printers you are considering. Is the code legible? Also consider the range of colours of the materials you want to code: could one coding solution be suitable for all?

- Line speed – will the coding solution keep up with your line speeds? Will the print be compromised if it cannot? Do you need to code across multi-lane production lines now, or will you need this capability in the future?

- Factory environment – if your coding environment is hot and dusty, for example, ensure that your solution has the right IP rating and features to perform reliably

- Available budget – not just the initial purchase price, but consider the overall cost of ownership and factor in reliability; by compromising on price you may pay more with unexpected breakdowns. Is leasing a better option, as a revenue rather than capital cost? During peaks in production, will rental give you the flexibility to meet coding demands?

- Testing – will your coding and marking provider offer a free trial? You need to be sure the machine is capable of meeting the demands you will place on it.

A wealth of options

There is a wide range of technologies designed to satisfy the key coding considerations, each with its own particular strengths in different applications.

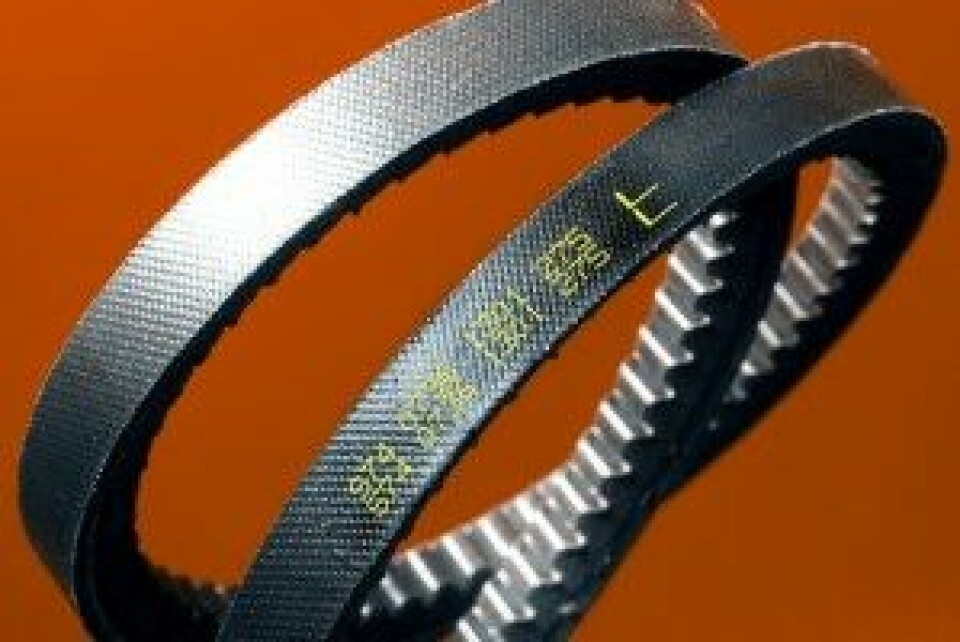

Laser: Particularly strong at delivering the 2D codes commonly required for effective automotive traceability, laser coding also provides a permanent code on a wide range of materials at high line speeds, including rubber and plastic, for example on rubber door trims or windscreen wipers. As there is no ink involved in the coding process and therefore no drying time, there is no risk of smudging when the coded product comes into contact with other products or handling systems soon after coding. Laser coders are particularly attractive due to their low downtime, high speed and the fact that there are no consumables involved. Together, these bring down the long-term cost of ownership in comparison with some other coding technologies.

Steered beam laser systems are highly versatile as they provide clear, consistent and perfectly formed characters in a variety of fonts and message formats, and enable the use of high-quality graphics and logos across a wide range of print sizes. They are particularly suitable where high-quality codes are required, for example to blend in with the style of pre-printed packaging.

Developments in design have also recently given rise to a new generation of lower cost compact laser coders, which offer an affordable alternative to other technologies whilst still maximising functionality.

Continuous inkjet (CIJ): Perhaps the most cost-effective choice, CIJ occupies an important place in coding, as it can print on almost any substrate. A wide range of inks is available for use with CIJ printers, including inks of different colours to ensure legibility on any colour substrate, plus UV-readable inks for anti-counterfeiting or water-removable inks for internal traceability.

CIJ can print from one to multiple lines of text and simple graphics at speeds of over 2,600 characters per second. Further versatility is delivered by the compact printhead that can be situated above, beside or beneath a production line – even traversing from side to side across the line if necessary. With lighter models increasingly available, the CIJ printer is capable of being quickly moved from line to line and is quicker to install and set up than laser coders.

Large character marking: Case coders are particularly well-suited to printing variable information onto secondary packaging such as cardboard boxes containing components; these outer cases usually require text and graphics which are easy to see.

Case coders can print to a high-resolution quality and are versatile enough for use on a variety of surfaces and materials. Easy to set up and adjust, their reliability and predictable cost of ownership make them suitable for production lines in a range of industries. They are also a cost-effective alternative to pre-printed boxes or labels.

Thermal inkjet (TIJ): TIJ printers offer a flexible coding solution for both outer cases and primary packaging. Although they have a smaller print area than case coders, these high-resolution coders generate superb print quality for premium packaging, and are a cost-effective solution for slower production lines or where production is not 24/7.

The case for coding

Less downtime on your production line means reduced costs for your business, and less downtime on your client’s production line due to an incorrectly coded component means less chance of you losing their custom. This is why the leading coders are built for durable coding during continuous operation; ultra-reliable, with long service intervals and low-cost maintenance to maximise production performance while minimising operating costs.

IP55 and IP65-rated steel enclosures offer protection against water and particle contamination such as carbon or rubber dust, preventing stoppages and offering high-quality continuous coding. Other features such as a positive air printhead also contribute towards reliable operation even in exceptionally dusty production environments.

The inks that are used are designed to withstand the effects of even the harshest production environments, offering resistance to heat, dust or oil and delivering longer-lasting codes. High-contrast pigmented inks offer better clarity for durable traceability right the way through to end use. These are available in a range of colours from white and grey through to yellow, black and blue to provide clear, legible codes on any colour material.

Some printers are also easily transferrable between lines, giving extra flexibility and saving time in production. Traversing printheads give greater flexibility for larger components, such as sheet metal, or across multi-lanes. Built for busy production lines where coding requirements frequently change, coders can be linked to a central PC to reduce the chance of manual errors when producing multiple products or for multiple customers.

The latest coders are easy to set up and manage on busy, highly automated production lines. Simple message selection, intuitive user interfaces and a large message storage capacity help to ensure that the right code is selected first time, every time. Automated message selection and remote monitoring, even by smartphone, further reduce the risk of code errors.

And with vehicle manufacturers often managing their supply chain on LEAN principles, effective coders enable a rapid reaction to fast-changing customer requirements.