Size me up, smart

As the only car still in production to feature in New York’s famous Museum of Modern Art, the smart has certainly succeeded in capturing attention. AMS reports on how the carmaker plans to take on the competition

The city car segment is about to get very crowded. Soon there will be an influx of new models from global vehicle makers, including the Fiat 500, Toyota iQ and Volkswagen Up!, as companies vie to attract customers cash with various combinations of style and fuel economy. What stands in the way of the newcomers is Daimler’s iconic city car model, the smart. The smart fortwo coupe has been in production since 1997 and the company plans to use that 11-year head start to stay well ahead of the competition as the city car market goes from lukewarm to red-hot. Located in Hambach, France, the smart production facility, or ‘smartville’ as it is known, appear to be in a remote location, but geography alone does not tell the whole story – the Hambach site (in the north-eastern region of the country) was chosen from 70 possible locations and there were good reasons for the choice. Plant Manager Bernard Lejeune explains, “Producing the car in France was less expensive than doing so in Germany, where labour costs are higher. In earlier years, this region produced coal and, following the demise of the industry, the government offered a number of incentives to locate to Hambach.

“This is a central location in terms of suppliers. As part of the Daimler group, we can take advantage of its supply strategies. Smart alone would have been too small to use the same suppliers, but located here, we can use all the same suppliers that provide parts to Daimler. This is key. Losing access to its supplier network by moving out of the region would not offset the gains made from reduced labour costs alone, in other lower-cost regions such as Eastern Europe.”

Daimler engineered the ‘smartville’ site

The plant was completely engineered by Daimler, for production by smart, with a team visiting from Germany to lead the operation. “In this region,” says Lejeune, “people speak French and German, so it was easier for the engineers from Daimler to come to Hambach and explain their processes to people who spoke both languages. Proximity in terms of culture and language also played a part in influencing the choice of site.”

The plant represents a total investment of FRF2.8 billion (approximately €400m in equivalent value at the time), with a further FRF1 billion (about €150m in equivalent value) invested in the supplier park surrounding the main production facility. The total investment in ‘smartville’ amounted to approximately FRF 8 billion (or about €1.2 billion in equivalent value). Constructed in a distinctive cross design, the plant has a production line running up and down each of its extended arms. Daniel Grimm, Quality Production Manager, explains: “Every wing is dedicated to a particular part of the production process.” Each floor is colour-coded and there is an open circle in the centre of the cross where the cars failing quality checks are parked before being repaired.

Close links to suppliers

The park is home to a number of suppliers delivering individual parts and completed modules to the production line in both just-in-time and just-in-sequence arrangements. These include Magna Steyr (providing the Tridion safety body frame), Plastal (customised body panels), Continental (cockpit), Magna Uniport (doors and tailgate) and ThyssenKrupp (drivetrain). Panopa acts as a logistics centre for small assembly parts, while MLT operates distribution.

The benefit of having your suppliers onsite is clear, with a shared responsibility for shipping and logistics costs. Most are system partners, meaning that they have worked with smart to develop a manufacturing strategy for the modules they deliver, while taking full responsibility for quality control. Others, like ThyssenKrupp, are assembly suppliers. Grimm says, “The assembly suppliers take parts from different suppliers that Daimler has chosen and assemble them for delivery to the production line. They do not have any responsibility for the parts received from the suppliers. If there are quality issues, they notify us and we resolve the problem.”

From the building of a chassis by Magna Chassis (painted either black or grey in the smart paintshop depending on body colour), to the final water ingress test designed to simulate a variety of wet weather conditions, it takes approximately seven hours to build a car. “We run a combination of coupes and cabriolets on the production line,” says Grimm, “although, for example, we can’t run ten consecutive cabriolets as it takes longer to add the roof.” He reveals that very few parts are stored near the production line. “Most parts are simply stored in delivery trucks. An advantage is that the storage area can easily be changed. If we need to move a station, we simply ask for the truck to be placed next to the new location.” The supply of wheels to the production line is a case in point. With different wheel sizes for the front and back of the cars, and for petrol, diesel and Brabus versions, delivery of wheel sets is a critical part of production. Arriving at the dock, trucks are automatically unloaded and the cargo is taken directly to the production line only a few metres away. “Continental builds stacks (of wheels) with barcodes, that are delivered just-in-sequence. There is a fullyautomated unloading procedure, with all remaining stock staying in the trailer until it is needed,” explains Grimm.

Stop system on the line improves quality

As part of the Daimler family of cars, smart is still in the process of incorporating the company-wide tooling standards. Other elements of the group’s process are already firmly in place. “We have the same reporting methods as any other Mercedes plant, in terms of the production process and expectation of production,” Grimm tells AMS.

“A defect can happen at any time and for any reason. If it happens a number of times, we analyse it but we want the defect to be recorded at the place of appearance. For this, we have installed a series of terminals on the production line that can be used to record the defect. Early traceability in the system allows us to organise the spare parts for the repair. When the car is finished, we can have all the parts needed waiting for the car, which also helps our logistics.” In a system similar to the one used by Toyota, there is a dual-coloured (yellow and red) quality stop system of hand-operated pulleys at intervals along the line. “(Pulling) Yellow means: ‘I was supposed to do this but I could not, for whatever reason, and now I am asking for help’, from a specialist for example,” says Grimm.

“Within the team, they can organise an evaluation of the problem. Red means ‘I have a problem on my assembly station that will have an effect on the next assembly station’. For example, if there is a problem with installing the carpet, the person installing the seat [next on the line] won’t be able to do so if the carpet has not been installed. So we might need to stop the line for a few seconds, with the reasons for that stoppage being analysed. Ninety-five per cent of available production time is supposed to be used for just that and as such, line stoppages are avoided at all costs.

“The takt time for each station is 107 seconds, with five cars being passed to each section of the line at a time. So if we stop a section of the assembly line, it means it would take five times 1 minute and 47 seconds to stop the other side of this line (considering that each wing has both an outward and return line sections). Then it would take ten cars times 1 minute and 47 seconds to stop the next line and so on. Within an hour, the whole plant would be stopped. This is why not stopping the line is so important.”

Automation is at about two per cent

In 2006, after a production run of 770,000 units, the original fortwo was replaced with a second-generation model. Production was halted between November of that year and January 2007 to make the necessary changes to the assembly line for the new model. This included installing a limited number of robots.

Berard Lejeune explains: “We have two robots to fit the screws, where the underbody is married to the chassis and two for the glueing stations, where the windscreen is added to the car.” When asked if the facility could benefit from extra automation, he says: “It’s difficult to look at operations and compare manual and robotic processes, when you have to look for the added value of every operation. Where we do have robots on the line, the job is very difficult to do manually.”

Daniel Grimm offers further insight as to why the decision was taken not to install more robots. “We actually have an automation rate of less than 2 per cent, the advantage of which is flexibility; we can, at any time, change an assembly station. That does not mean that people on the assembly line have to do all the jobs. We pay a lot of attention to ergonomics, focusing on worker comfort within the individual stations,” he says.

He explains the decision to automate the marriage and glueing stations: “At the marriage station approximately 50 screws are added to the underside of the car. Clearly, this is something that is better done by machine. Key to this process are the four screws that hold the rear axle to the chassis. These are inserted by robot and are self-threading. From an ergonomic aspect, its very hard to lift the glass, and installing manipulator arms speeded up the process. However, the positioning of the glass is still done by hand, assisted by the handling equipment.”

Improving the production line is an on-going process according to Grimm. “We undertook a kaizen project with a view to making improvements to the production line. One of the outcomes was to add a parts wagon to some stations. While the worker adds parts to the underside of the car, the parts wagon travels along with the car so that the worker doesn’t have to return to a fixed parts bin. Also, seats that were installed manually on the older model are now added using a handler.” Takt times have improved considerably since the production line was revamped for the new model, also as a result of kaizen.

Other features of the production line include approximately 20 workstations that allow individuals with reduced physical capabilities to continue working. “Our staff are very motivated, they want to work. These workstations allow them to be productive while recuperating from illness or injury. This set-up allows for that.”

It’s all about quality

Smart has announced plans to start exporting its products to China in 2009. This is a two-pronged strategy, designed to introduce the fortwo to the world’s highest growth car market, while challenging the locally-produced Shuanghuan Noble, the notorious ‘smart clone’ on its home territory. Grimm says that there never was a question about exporting the car in CKD form. “We will deliver a finished product. We discussed supplying the car CKD for assembly in-country, but when you consider the industrial security aspects, we did not want to hand over the responsibility to another manufacturer.”

There is also the question of liability. “If there is a vehicle accident, you (the manufacturer) want to be sure that the car has left with the right screws, for example. We can supply that information for up to 15 years. Fourteen years from now, I could tell you the date and time your car was produced. We have to provide this kind of information, for liability issues. We have to be sure that the car has left the factory in perfect condition,” he explains.

“The cars we manufacture are exported to more than 37 countries. The cars leave the plant in France and are shipped the same day. If any defect is found, you need to be sure of traceability. Over the last few years, we have increased this. You can trace cars by VIN – this shows which cars are on which ships and when they are scheduled to arrive at their destinations. If this traceability does not work in the field, it’s useless, so dealers need to have access to our systems, with the ability to update the data,” adds Grimm.

Suppliers are held to similarly rigorous checks, to assist with parts tracking and security. “Parts are marked with barcodes, to help with traceability. ThyssenKrupp builds up a complete rear axle, incorporating the axle, engine and brakes. The brake supplier makes his brakes, each part of which is marked for traceability. ThyssenKrupp keeps a record of which brakes are assembled on which axle and we keep records of the full module. There is a cascade of information, so if someone in the field says that they had an issue with a brake, we can trace the part’s history upstream,” Grimm tells AMS. “You need to have good traceability not only on the manufacturing side, but also with suppliers and aftersales, so that there is full accountability.”

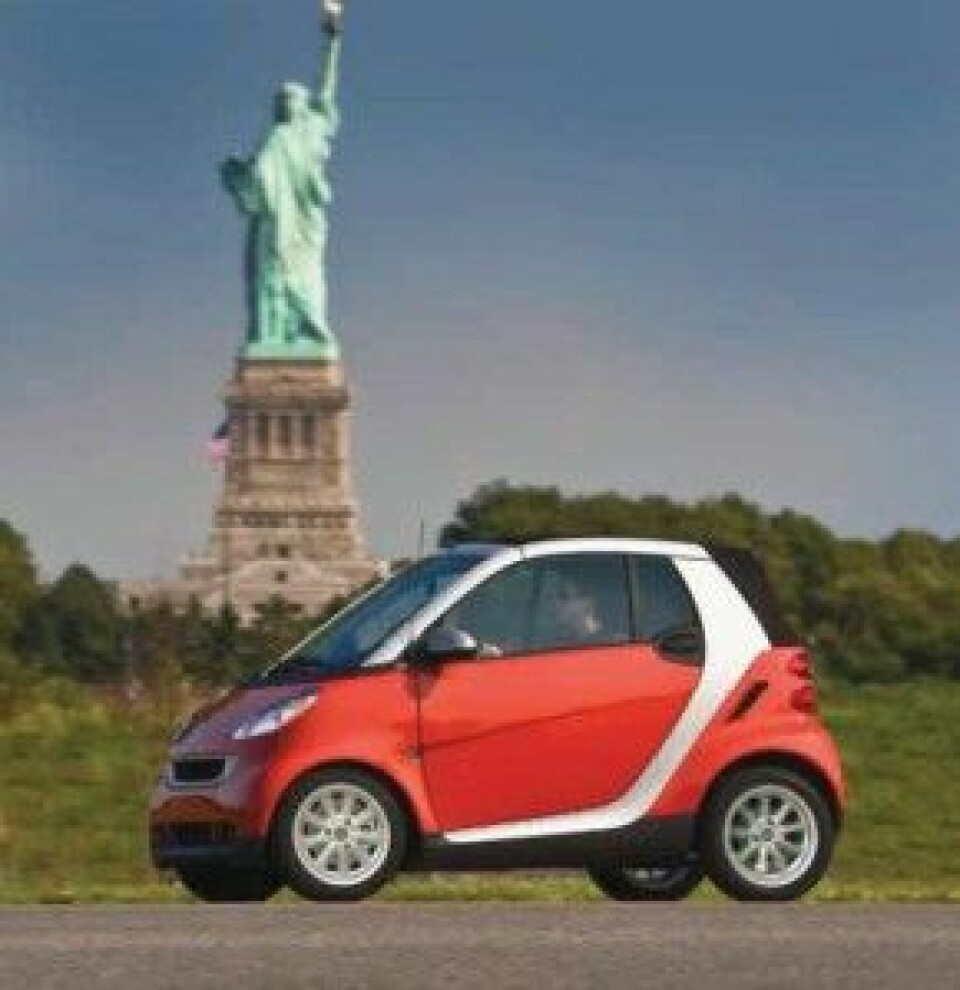

Getting smart stateside

Earlier this year, the fortwo was introduced to the American market. Penske Automotive Group, the official importer in the United States, is already reported to be interested in increasing its allotted annual supply of 30,000 units, claiming that the market could support twice that number. “Extending production to supply Penske Automotive Group is under serious analysis,” says Grimm. “The main issue is currency. If the dollar continues to fall, we might reach a point where we deliver too many vehicles and start to negatively influence the return on the investment. The facility is at its maximum production capacity and there would have to be more investment to produce the requested number of vehicles.” There is potential for extra production in the current operational arrangement, with the possibility of a Saturday shift being added to the two shifts now running on weekdays. The Hambach plant layout lends itself to expansion. “Having the plant designed as a cross means that you can extend any arm of the building to add production space,” Grimm points out.

1989 Swatch inventor Nicholas Hayek announces idea for adaptable citycar

1994 Mercedes-Benz partners with Swatch in joint venture

1997 smart makes its debut at the International Motor Show in Frankfurt

1998 Full production begins in the new Hambach plant in France

Hambach produces 200,000 cars annually. The USA will be the 37th country into which the smartfortwo has been introduced

This is not the first time that smart has attempted a North American introduction, the first smart model having been available through a limited number of Canadian Mercedes- Benz dealers. But this is the first official US launch, and the reaction has been favourable. “This is the perfect time for smart to be arriving in the US. The commercial environment is right, and buyers have never been so sensitive to environmental concerns. The smart’s arrival in the US has opened a whole new discussion. It’s not just about smart, it’s about how there’s an alternative transport solution.”

Sales of the smart for two have doubled year-on-year since the launch of the new model, a strong position from which to battle the latest city car offerings. As for the California mandated 2014 regulation that manufacturers supply a percentage of zero-emission vehicles in line with total sales (matched by 12 other US states), a planned electric version of the for two (100 of which are currently testing in London, UK) will likely play a part in fulfilling any requirement. “The current focus on the environment is a great opportunity for smart,” says Grimm. “We are a showcase for Daimler’s environmental aspirations, a window that shows how the carmaker can give customers a personal mobility solution that is reliable and fuel-efficient.”