India: The last BRIC standing

As other emerging markets decline, India is still seeing significant investment by global vehicle-makers

Vehicle-makers are stepping up their campaigns to crack the difficult Indian automotive market after the country became the most promising of the emerging BRIC nations following market collapses in Brazil and Russia and a cooling in China. Combined car, commercial and motorbike sales recorded their best year for five years at 19.7m in the 12 months ending March 2015, with cars rising 4% to 2.6m. Sales of medium to heavy commercial vehicles reversed a slump to climb 16%, to the relief of their makers, while sales of motorbikes and scooters were back almost at full throttle, rising 8% to just over 16m, according to the local manufacturers’ association, SIAM.

To sell in India, almost without exception you have to make in India, and production hit 23.4m cars, motorbikes and commercials in the 2014-15 financial year, up 9% from the year before to a five-year high. According to SIAM, the automotive industry in India now accounts for 7.1% of the country’s GDP and employs around 29m people. And there is still plenty of room for expansion; analyst IHS Automotive believes that car production will rise from 3.2m in financial year 2014-15 to 6m by 2020. Newcomers might be finding it tough to break the long-term stranglehold on the car market of Maruti Suzuki, which took a 45% share in 2014-15, but they still anticipate plenty of future growth.

Renault, for example, points out that at the moment car ownership in India is just 20 vehicles per 1,000 inhabitants, compared with 105 in China, 300 in Russia and 600 in Europe. In a country with a population of 1.25 billion – not far behind China’s 1.36 billion – that is an untapped market to attract any ambitious carmaker; Renault reckons it will hit 5m sales by 2020 and is aiming for a 5% share, up from 2% at present.

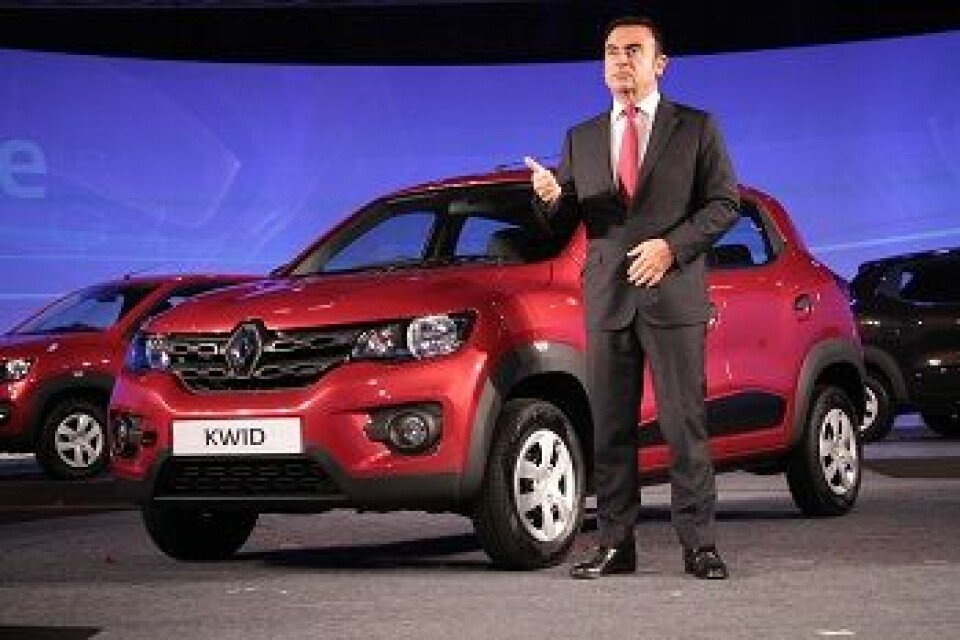

The French OEM will make its most determined push yet this September, when it starts selling the locally styled Kwid, an A-segment micro-SUV retailing at a price low enough to lure business away from the dominant maker of budget cars, Maruti Suzuki. The keen pricing is mainly down to the parts localisation, which is among the highest in the world, the company told AMS (see interview below). After several false starts in the country, Renault predicts that this will be its breakthrough model.

The French vehicle-maker has invested money in a new engine facility at the plant it shares with alliance partner Nissan in the automotive hub of Chennai, on the east coast – and it is not alone in piling in the investment cash. Honda, India’s fourth-largest carmaker in terms of sales with a 7% share, is plotting plant number three, this time in Gujurat, the western state which is vying to become the third automotive production hub after Chennai and Pune. The CEO of Honda India told news agency PTI in July that it had started buying up land in the state for a greenfield site. Back in March, Honda announced that it would invest a further 3.8 billion rupees ($59.6m) to increase the capacity from 120,000 to 180,000 units per year at its Takapura, Rajasthan plant, which was only opened in February 2014. Honda reckons it is the fastest growing car brand in India, based on its 44% growth in the 2014-15 financial year.

Maruti Suzuki has also said that it will expand by building a new plant in Gujurat, after admitting in June that it had no room to boost capacity at its two plants in Haryana state, which together can produce 1.5m cars per annum. Maruti sold 1.17m cars in the 2014-15 financial year, led by the evergreen Alto A-segment car but also the Dzire booted supermini, which in a rare event overtook the Alto in June sales this year to become India’s bestseller.

While carmakers are closer to finding the secret to success in battling the mighty Maruti, commercial vehicle manufacturers are struggling to make their business pay as the sector pulls out of a long-running trough. Even the dominant Tata Motors is having problems. Sluggish van sales hit overall commercial sales, which at 614,961 in the 2014-15 financial year were still below the peak of 810,000 in 2011-12. But medium and heavy commercial vehicles were up 16% on the year and are still going strong now. Tata’s truck sales rose 19% in June to 11,450 units, while third-placed Ashok-Leyland’s sales climbed 46%.

The return to health of the big truck market will give Tata Motors cause for hope after a loss of 47.4 billion rupees ($730.6m) in the last financial year, when it launched the Ultra light truck as well as the Zest and Bolt small cars. Poor sales of the latter will be giving the OEM a headache this year too, although IHS says the growth of the truck market “is a big positive factor for the company”.Fourth-placed commercial maker VECV Eicher, a joint venture between Eicher and Volvo Trucks, is in a better position, and claimed in its annual report for the last financial year that it was “the only CV company to remain profitable in every quarter during the longest downturn in the recent decades for the Indian commercial vehicle industry”. But margins are nowhere near the double-digits achieved by Indian motorbike makers. The Indian truck industry might be just as over-reliant on old technology and designs, but Eicher could manage only a margin of 3.7% in the most recent financial year.

In the first four months of the year, heavy-duty trucks were up 37% compared with the same period last year, but medium trucks were flat and light trucks were down. In May, VECV Eicher’s managing director, Vinod Aggarwal, told the Times of India that makers were playing a waiting game until internal investment promised by prime minister Narendra Modi materialised. “Mining has seen significant improvement but the road construction sector is not growing as infrastructure projects are not taking off yet,” he said.

Meanwhile, Ford opened its second plant in March, also in Gujurat, to complement its Chennai facility and make the new Figo Aspire booted A-segment car. This new plant in Sanand pushes Ford’s investment in India to $1 billion and doubles its installed capacity to 440,000 vehicles and 610,000 engines.

Second-placed seller Hyundai will need another plant to fulfil its expansion desires, according to IHS Automotive’s Gaurav Vangaal, senior forecast analyst for the region, while long-time Indian player (and struggler) Fiat announced in July that it would build a Jeep plant with its joint venture partner Tata Motors near Pune. Production of an as yet unnamed model is likely to start in 2017.

Exports the key to success

The disparity between Ford’s Indian capacity and sales looks like madness – last year the brand sold just over 75,000 in the country, mainly its successful B-segment SUV the EcoSport. But Ford also sees India as an export base. Last financial year, Ford was the fourth-biggest exporter from the country with just over 81,000 units, ie more than its sales in India. The vast majority were EcoSports from the Chennai plant, with Europe being one destination.

Ford is now gearing up to export the new Figo hatch from its Sanand plant as the next Ka A-segment car, and earlier this year Ford CEO Mark Fields was quoted by the Indian Express as saying that he wants to triple exports from India within five years and expand the number of export markets from 37 to 50. “[We will] pitch for India as an export hub,” he said.

India’s long-running motorbike success story continues, with two-wheeler sales up 8% to just over 16m in the financial year ending March 2015, and production up 10% to just under 18.5m in the same period. That is not far off the 18.9m made in China over the same period. With Chinese volumes in decline, India is poised this year to overtake its neighbour for the title of world’s biggest motorbike producer – a huge achievement.

TVS, now the country’s third-biggest brand after it overtook Bajaj, said in its annual company report that it expected similar growth in the overall market this year, at around 9%, with the continuing popularity of scooters driving the rise. In June, for example, scooter sales rose 14%, pushing total two-wheeler volumes up by 4%.

As ever, the two-wheeler market is dominated by Hero, which took a 40% market share in the 2014-15 financial year with sales of 6.4m, according to SIAM figures. That was led by the budget Splendor, which costs just 46,300 rupees ($713.8) before local taxes. Former partner Honda is fast catching up thanks primarily to its strong scooter range; sales were up 20% the last financial year to 4.3m and its Activa scooter was the second-biggest seller of all in May this year.

Premium bikes are another growth market, rising 19% in the last financial year. This has propelled the veteran Royal Enfield, owned by Eicher Motors, to new heights. The company reported that it made 300,000 bikes in 2014 at its two Chennai factories, up from around 50,000 in 2010, as its ‘retro-cool’ machines such as the 350 Bullet, a bike that can trace its roots back to 1949, captured the local imagination. This surge in sales pushed the brands’ profit margins to 22.5%, Eicher declared in its 2014 report, saying this was “better than that of any other motorcycle company in the world, and possibly the highest level compared to any automotive brand globally”. The manufacturer will build a third plant, also not far from Chennai, to reach a capacity of 600,000 in 2016.

Bike sales by brand for the 2014-15 financial year (sales, increase, market share)

- Hero: 6,431,686 +5% (40%)

- Honda: 4,263,967 +20% (27%)

- TVS: 2,107,696 +20% (13%)

- Bajaj: 1,770,778 -16% (11%)

- Yamaha: 565,273 +17% (4%)

- Suzuki: 340,506 -4% (2%)

- Royal Enfield: 324,055 +60% (2%)

- Mahindra 2 Wheelers: 165,344 -18% (1%)

- Piaggio: 28,062 -12% (0.2%)

- Harley Davidson: 4,641 +141% (0.03)

*SIAM figures

[sam_ad id=17 codes='true']Last year, the top exporter was Hyundai with 191,221 units, followed by Suzuki and Nissan, each shipping around 120,000. Exports are key to domestic success too, argues Vangaal at IHS, because it gives the economies of scale necessary to keep sticker prices low in price-obsessed India. “Look at what VW has done with Vento [a Polo-based saloon]; they were struggling, then they started exporting, and they’re doing much better,” Vangaal states. The Vento is made in VW’s factory in Chakan, near Pune, and the company exported around 55,000 units last year, mainly to Mexico. VW’s India sales in June this year were up 31% to just over 4,000 thanks to the success of the Polo and Vento, moving above Nissan and a struggling Chevrolet.

It is not only cars themselves that are a focus of export strategies; Honda, for example, wants the country to be a global parts hub too. In July, the president of Honda Cars in India, Katsushi Inoue, told news agency PTI that he wanted a 50% increase in exports of parts such as forgings, transmissions and engine parts made at its Tapukara plant, adding the US, China and Canada as destinations.

Meanewhile, Renault-Nissan’s CEO, Carlos Ghosn, admitted at the launch of the Kwid earlier this year that “India is not an easy market”. But he added that the rewards for succeeding will be huge: “If an affordable car succeeds in India with big numbers, it will be successful in whichever global market we launch it in.”

Unlike current Renaults built and sold here, the SUV-styled Kwid is designed locally using a platform developed specifically for markets like India. That helps to keep the cost down and give it a reported starting price of just 300,000 rupees ($4,627). AMS spoke to Pascal Felten, Renault’s head of manufacturing and supply chain for Africa, India and Middle East, to find out how the OEM made it happen.

AMS: How will the Kwid succeed in the small-car market?

Pascal Felten (PF): Kwid is well-equipped. That’s not always the case for cars of that price.

AMS: How have you managed to keep the price low?

PF: We made it for the Indian market, by Indian designers and by Indian suppliers. The main reason is that we buy all parts in India. It’s probably [the] only car in the world so localised, at around 98 or 99%. We also make our own engines, cheaper than anywhere else.

AMS: The Kwid has a 0.8-litre engine also made on your Chennai site – how did you reduce the costs?

PF: There we also deeply studied the cost of it. It’s made in a new building that itself is very innovative because it only has two walls; the other two [sides] are open. It’s cheaper but also the temperature in summer is 5% lower than [the] other building.

AMS: What is the utilisation rate of Chennai – anywhere near its 400,000 capacity?

PF: Volume last year was around 310,000, roughly [the] same this year. With a full year of Kwid manufacturing, [it] should be hopefully more. In the future we are planning to have full capacity of the plant, but not next year.

AMS: What are the exact figures for the Kwid in a full year?

PF: We are planning a capacity of 20 per hour, more than twice that of the Duster [B-segment SUV]. We sell around 40,000 Dusters a year in India.

AMS: What is the local content of the Duster?

PF: Duster is around 70-75%. We are importing a lot of stamping parts from Romania because we are making from the mother plant. We are working to localise these parts; they should be cheaper to make locally.

AMS: You’ve just started making the Lodgy MPV. How is that going?

PF: It’s starting quite well. The quality and feedback from the customers is good. It was a quick ramp-up so I’m quite happy with the launch.

AMS: Are you responsible for Nissan output in the Chennai plant?

PF: No, [the] managing director of the plant is from Nissan. I am responsible for Renault output; there are French Renault guys in the plant.

AMS: How does the supplier network compare with Russia, Brazil and China?

PF: We find nearly all technologies in India, [but] some we have to buy abroad, that is why we are not 100% localised for Kwid. We can’t find sensors, for example. It’s clear that we don’t always find the best suppliers as we do in Europe, which is also the case in Russia, so we have to train them to make sure they supply to the right standards.

AMS: Will the CMF-A platform yield more models from Renault?

PF: Datsun will launch a car on the platform next year but there will be also be more.

AMS: What are the key advantages of CMF-A in terms of cost, compared with the Logan M0 platform?

PF: Logan was too expensive for India. CMF-A is made and partly designed by Indian people, and locally produced with suppliers. It’s a platform for India.AMS: Will you carry on making the Scala and Pulse [a rebadged Nissan Sunny and Micra, respectively]?

PF: There are discussions whether or not we should continue to make these cars, but at the moment the 'No' decision has been made. Volumes are quite low, which makes the cars quite complicated.

AMS: Are they too expensive?

PF: It’s probably not the only reason we don’t find enough customers, but it’s certainly a reason, because the platform was not designed and optimised for the market.

AMS: Why do you think Maruti Suzuki is so successful?

Because they have had a presence here for a very long time; because they are Indian, or at least [have] a very high level of ‘Indianisation’; and because they have the right product. And they very widely spread in India. Kwid is a fantastic opportunity; it’s the right car for India and it will help the company accelerate the dealer network to the next level.