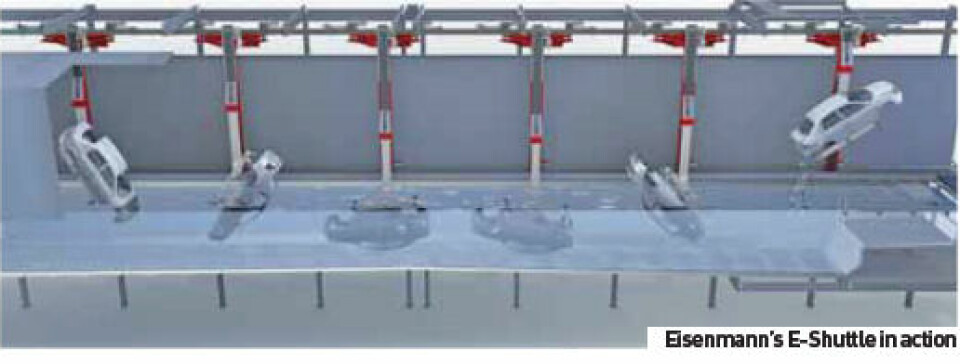

Eisenmann introduces the E-Shuttle paintshop conveyor

The new E-Shuttle paintshop conveyor system from Eisenmann combines dipping electric monorail systems (EMS), heavy-duty EMS and the VarioShuttle. The result is a highly-fl exible system which offers individually programmable dipping curves and process times for each basin. The rotary principle allows every possible mode of operation to be achieved, optimizing fl ooding and draining characteristics. The E-Shuttle has three programmable axes: traversing, lifting and turning. In addition to customised dipping curves, these allow virtually limitless modes of operation, such as roof up, roof down or any position in between. Bodies are dipped with a combination lifting/ turning movement, meaning that the bodies can be turned through 360° even when vertical. This allows the bodies to be quickly fl ooded and fully drained, reducing bath entrainment and consumption of chemical solutions. E-Shuttle guarantees high surface quality for every body type, with the added benefi ts of sustainable process control and lower operating costs in comparison to conventional systems. Due to its compact design and low net weight, the energy-effi cient E-Shuttle system will be of particular interest to companies developing greenfi eld car plants. Eisenmann’s VarioShuttle system remains available for large bodies weighing more than 1,000kg. www.eisenmann.com