Nissan material specialists explore lightweight NVH technology

Continuing its meta-material projects, the OEM has developed an acoustic barrier innovation that is 75% lighter than conventional sound insulation materials

Nissan is working on a new NVH application with a dual advantage of helping to make cabins quieter while also assisting energy efficiency. The new lightweight sound insulation material, known as acoustic meta-material, is the latest step in Nissan’s long-term materials development.

The OEM began its research on meta-material technology in 2008. Back then, meta-material was used in high-sensitivity antennas used for electromagnetic wave research. Nissan has explored how this application of meta-material technology could be extended to include sound waves, work which has led to the successful development of acoustic meta-material.

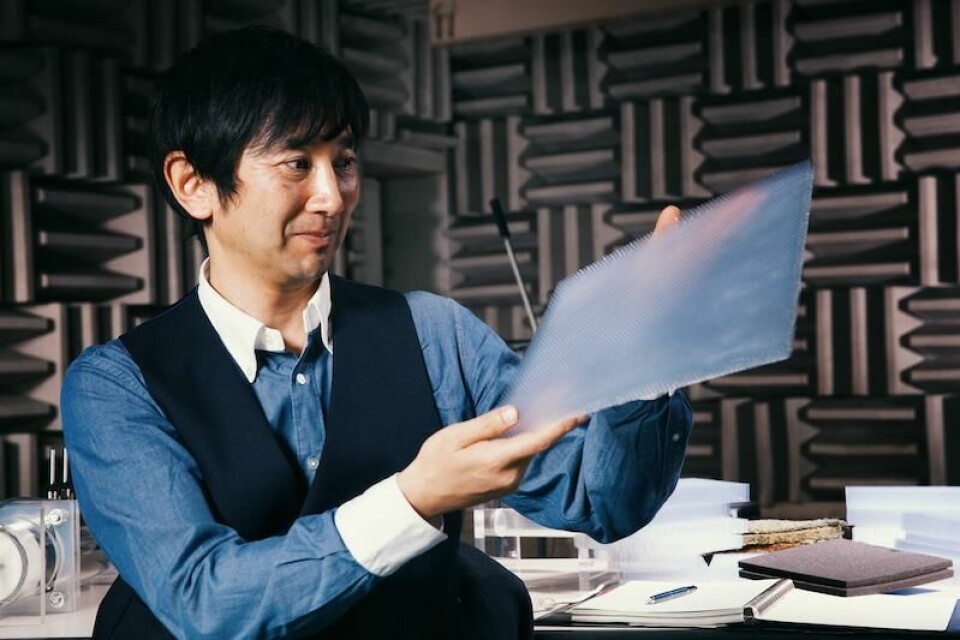

Susumu Miura, advanced material engineer at Nissan, highlights the importance of improved NVH technology as the e-mobility age advances: ”When you drive, you hear road noise. Electric vehicles have no engine sounds, making them quieter – but that makes road noise more distinct.”

Reducing that noise is a challenge, Miura adds, and it is this challenge that prompted Nissan to developed its acoustic meta-material.

The makeup of the new material is simple – a lattice structure, covered with a plastic film, controls air vibrations thereby limiting the transmission of wide frequency band noise (500-1200hz). Road and engine noises comprise soundwaves in this band and, conventionally, OEMs use heavy rubber or bitumen mats to isolate them. OEMs, in Germany particularly, have also investigated the alternative of sprayable, liquid-applied sound deadening (LASD).

Nissan says its new acoustic meta-material weighs just 25% of the equivalent-sized rubber matting while providing the same degree of sound isolation.

Because of its simple structure, Nissan says, the material’s cost competitiveness in terms of series production equates to or improves upon current heavier materials. As such, the material can be rolled out to models where the use of sound insulation materials is currently cost or performance prohibitive.